Process and an apparatus for producing coarse count and tridimensional crimped multifilament bcf yarns, yarns thus obtained and applications thereof

a multi-filament bcf and yarn technology, applied in the field of yarns, can solve the problems of uncontrolled chemical-physical, mechanical, chemical and physical properties of multi-filament bcf yarns available, and achieve the effects of improving the agglomeration and homogeneity of bcf yarns, and increasing the volume of yarns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052]While the invention is susceptible to various modifications and alternative constructions, certain preferred embodiments are shown in the drawings and will be described in detail below.

[0053]It should be understood, however, that there is no intention to limit the invention to the specific illustrated embodiments, but, on the contrary, the invention is intended to cover all modifications, alternative constructions, and equivalents that fall within the scope of the invention as defined within the claims.

[0054]In the following description, therefore, the use of “for example”, “etc.”, “or / or else” means non-exclusive alternatives without limitation, unless otherwise indicated; the use of “also” means “including, but not limited to” unless otherwise indicated; the use of “includes / comprises” means “includes / comprises, but not limited to” unless otherwise indicated.

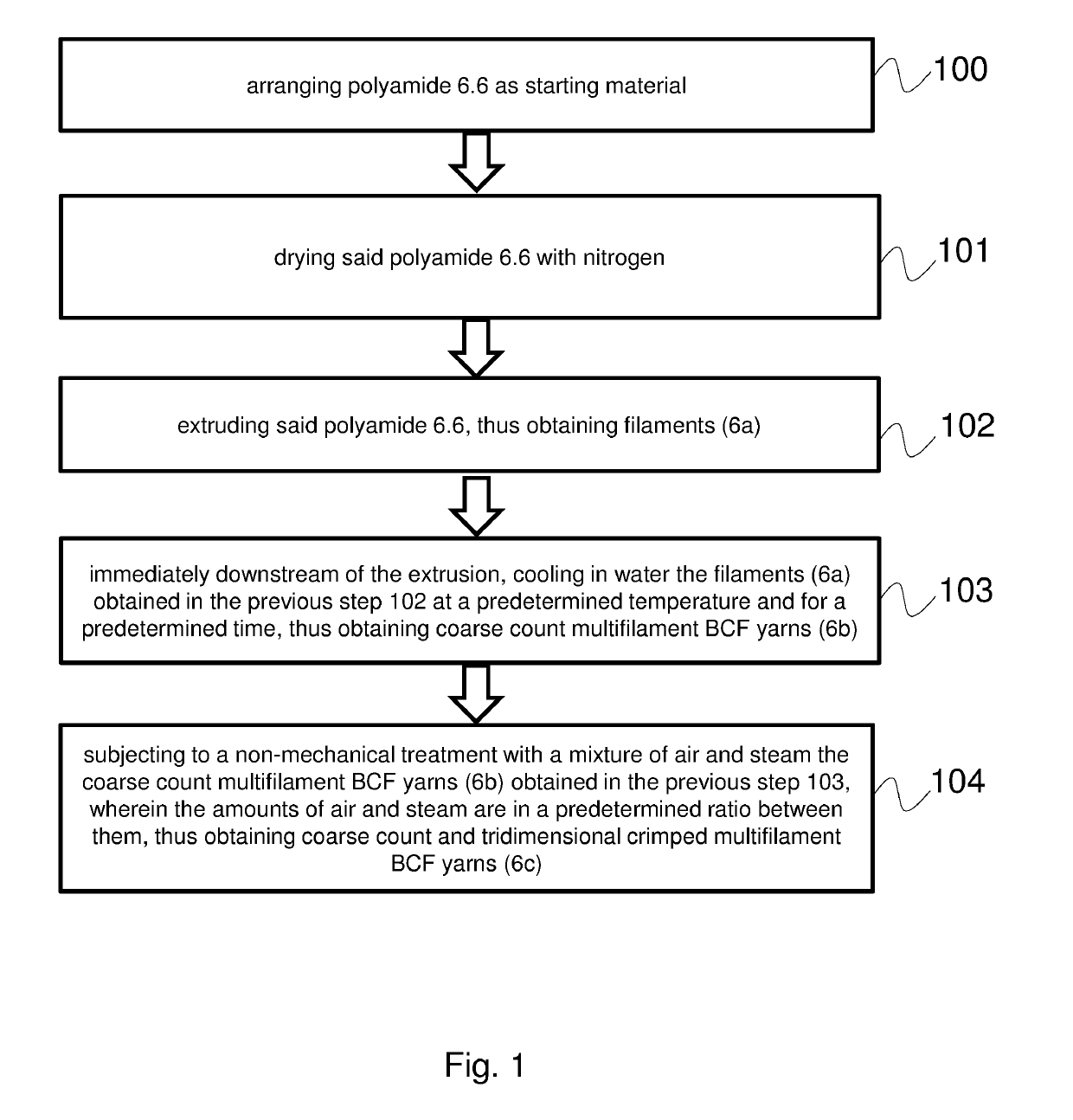

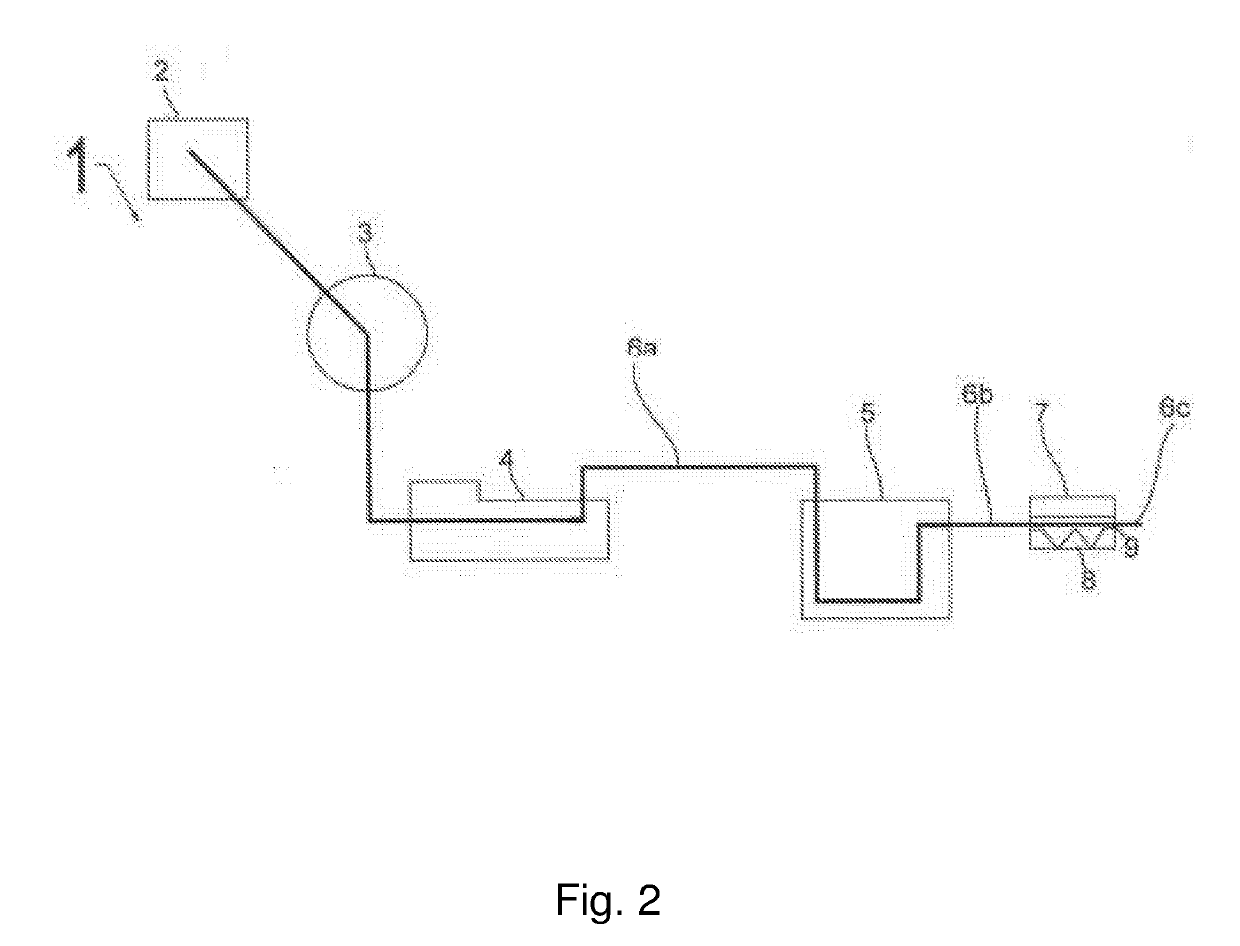

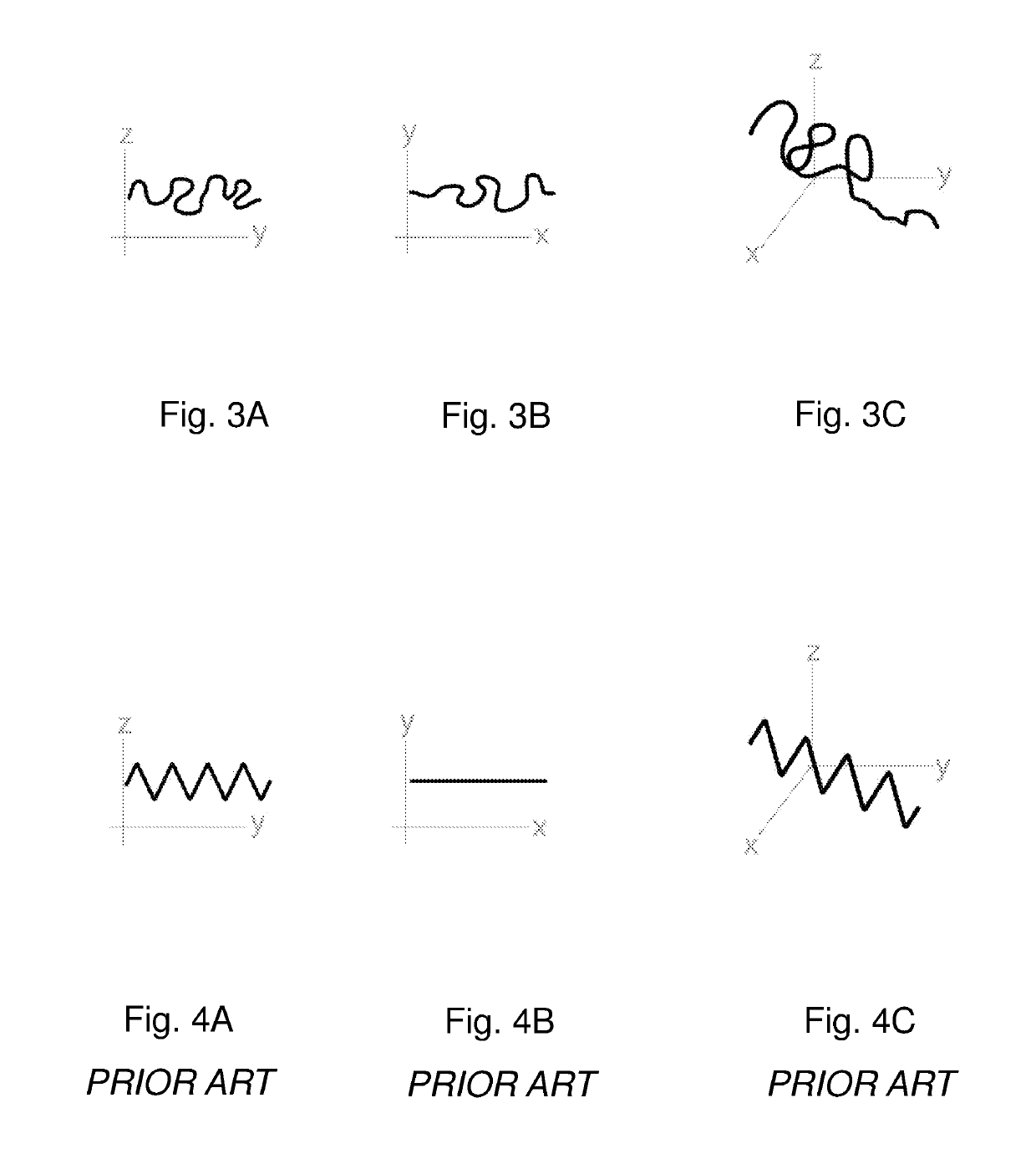

[0055]The process and the apparatus for the production of coarse count and tridimensional crimped multifilament BCF ya...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com