Modified lignin and separation methods

a technology of lignin and separation methods, which is applied in the field of processing of lignocellulosic biomass, can solve problems such as difficulty in valorisation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]According to a first aspect the present invention provides a method of processing a lignocellulosic feedstock, the method comprising:[0015]heating the lignocellulosic feedstock in a solvent mixture comprising an acid and at least 80% by volume of n-butanol to produce a reaction mixture including a butylated lignin.

[0016]The composition of solvent mixtures used for the methods of processing a lignocellulosic feedstock described herein does not include the presence of water, or other components that are present in the lignocellulosic feedstock itself. A dried cellulosic feedstock such as a sawdust may have from 5% to 20% water content. An undried lignocellulosic feed stock may have higher water content.

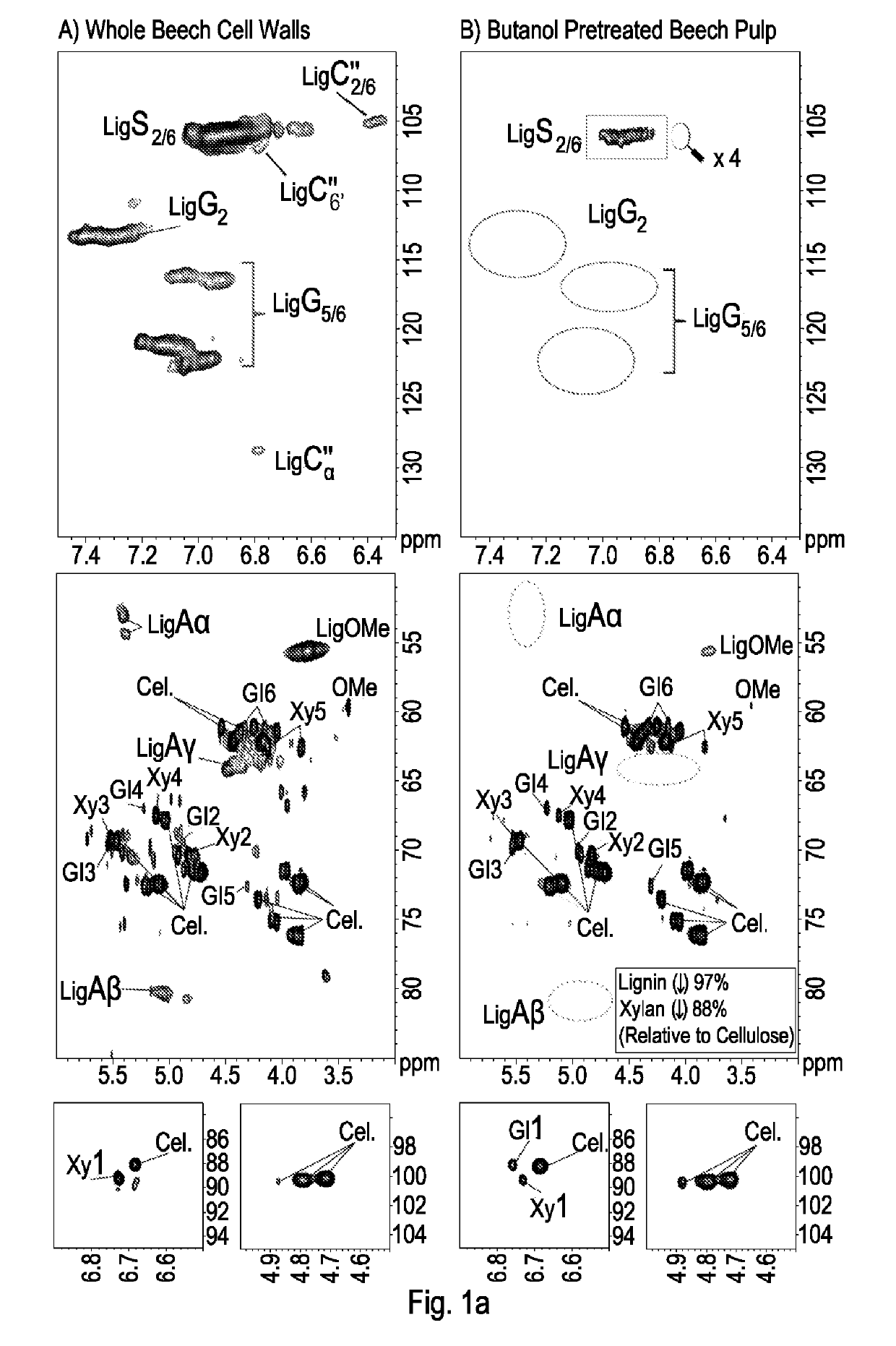

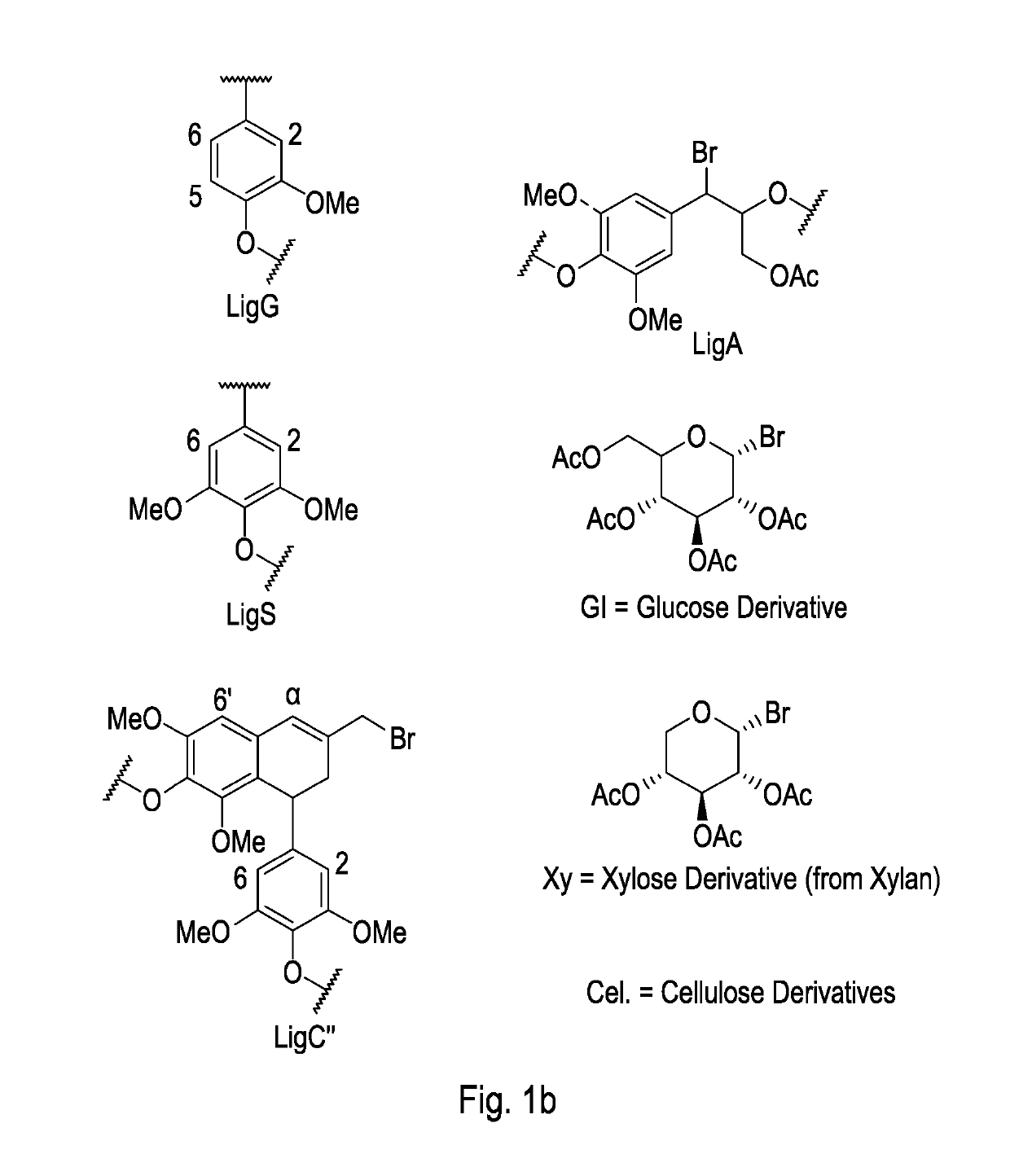

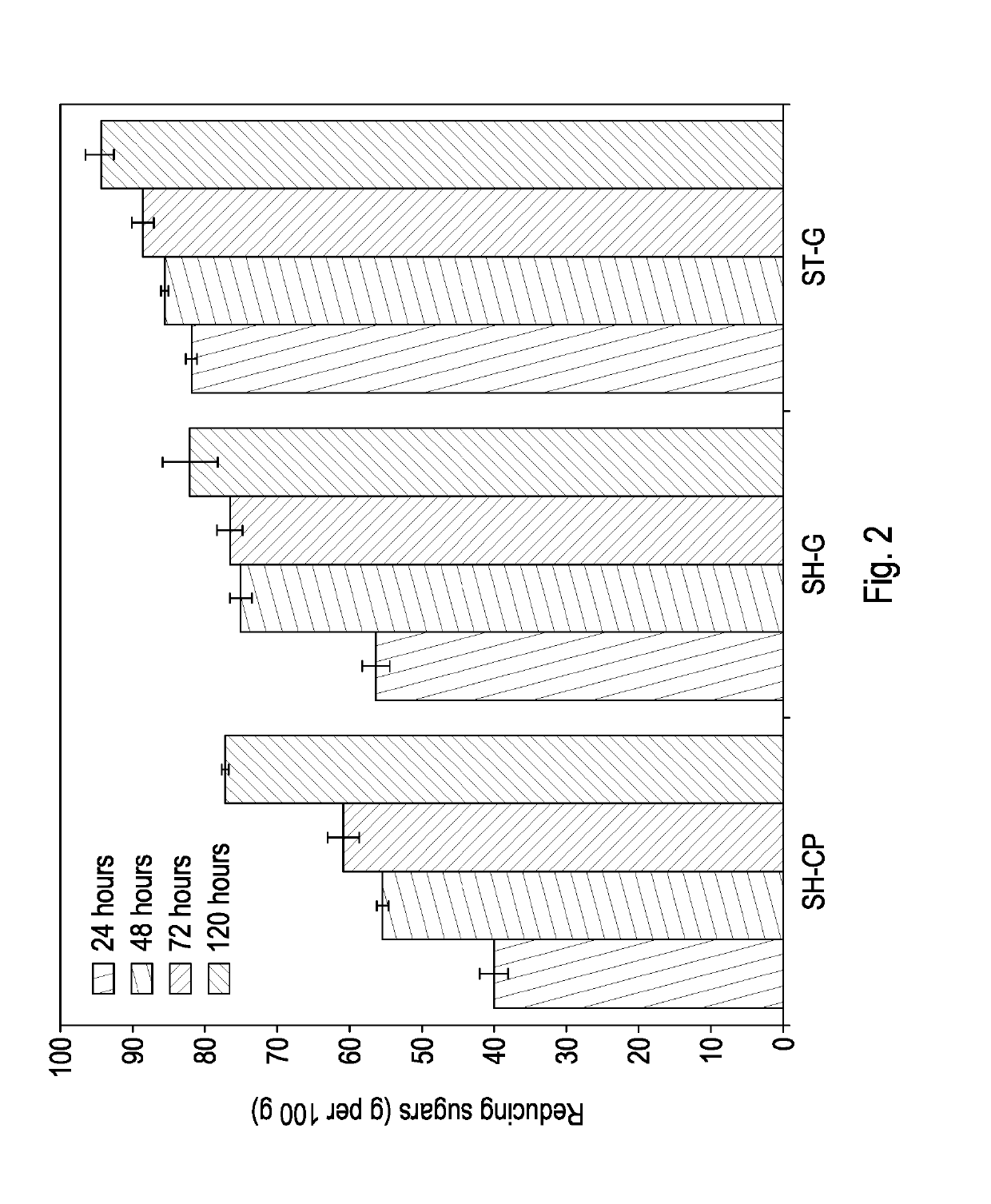

[0017]The production of a butylated lignin by the methods described herein has been found to produce a reaction mixture from which good quality lignin, cellulose and hemicellulose products may be readily obtained as described further hereafter. With some feedstocks, especially woo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com