Dynamic range of motion orthosis

a dynamic range of motion and shoulder technology, applied in the field of shoulder and arm orthotics, can solve the problems of limited range of motion (with or without muscular control), reduced motor skills, and atrophy, and achieve the effect of facilitating rotation of the flexion-extension assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

third embodiment

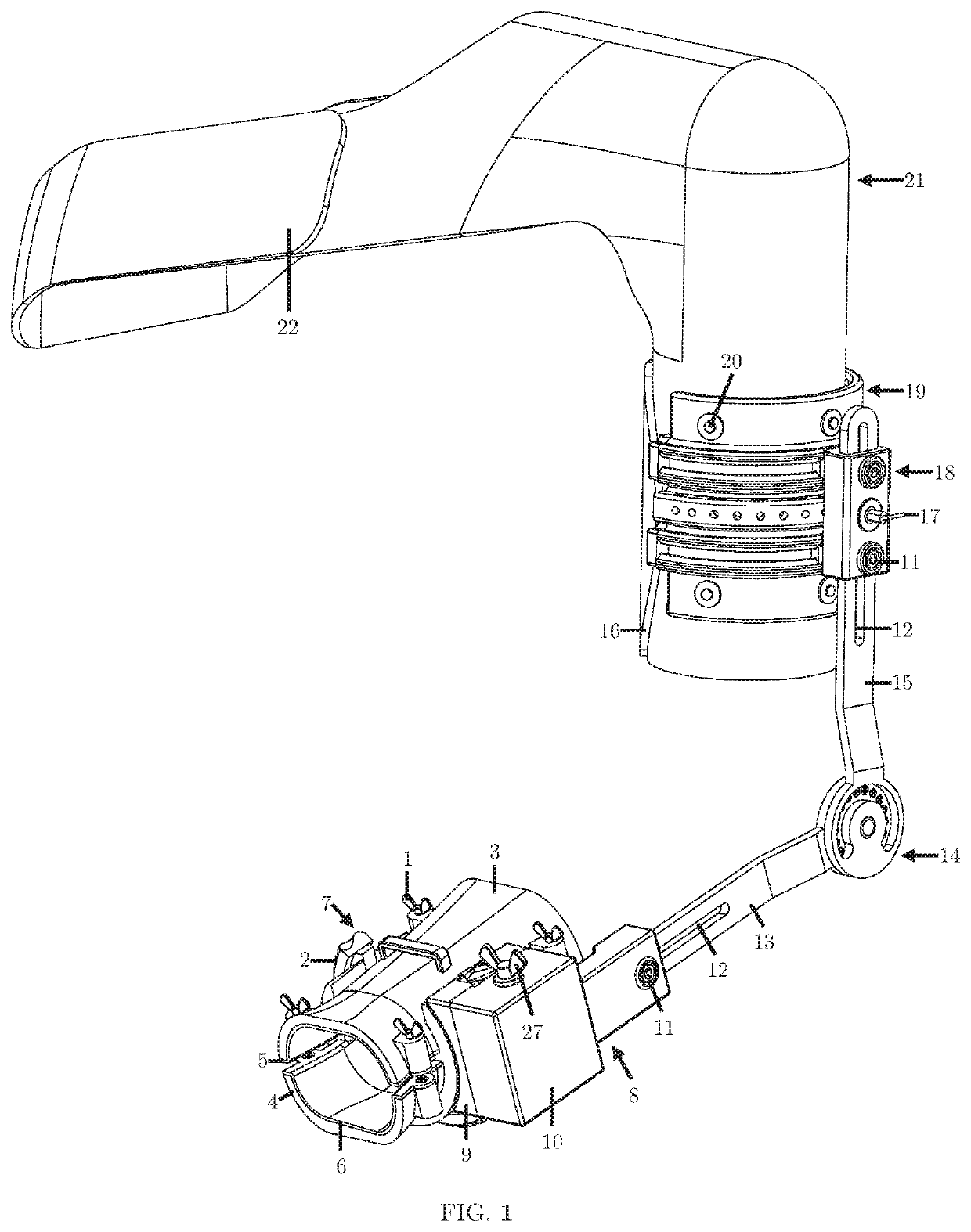

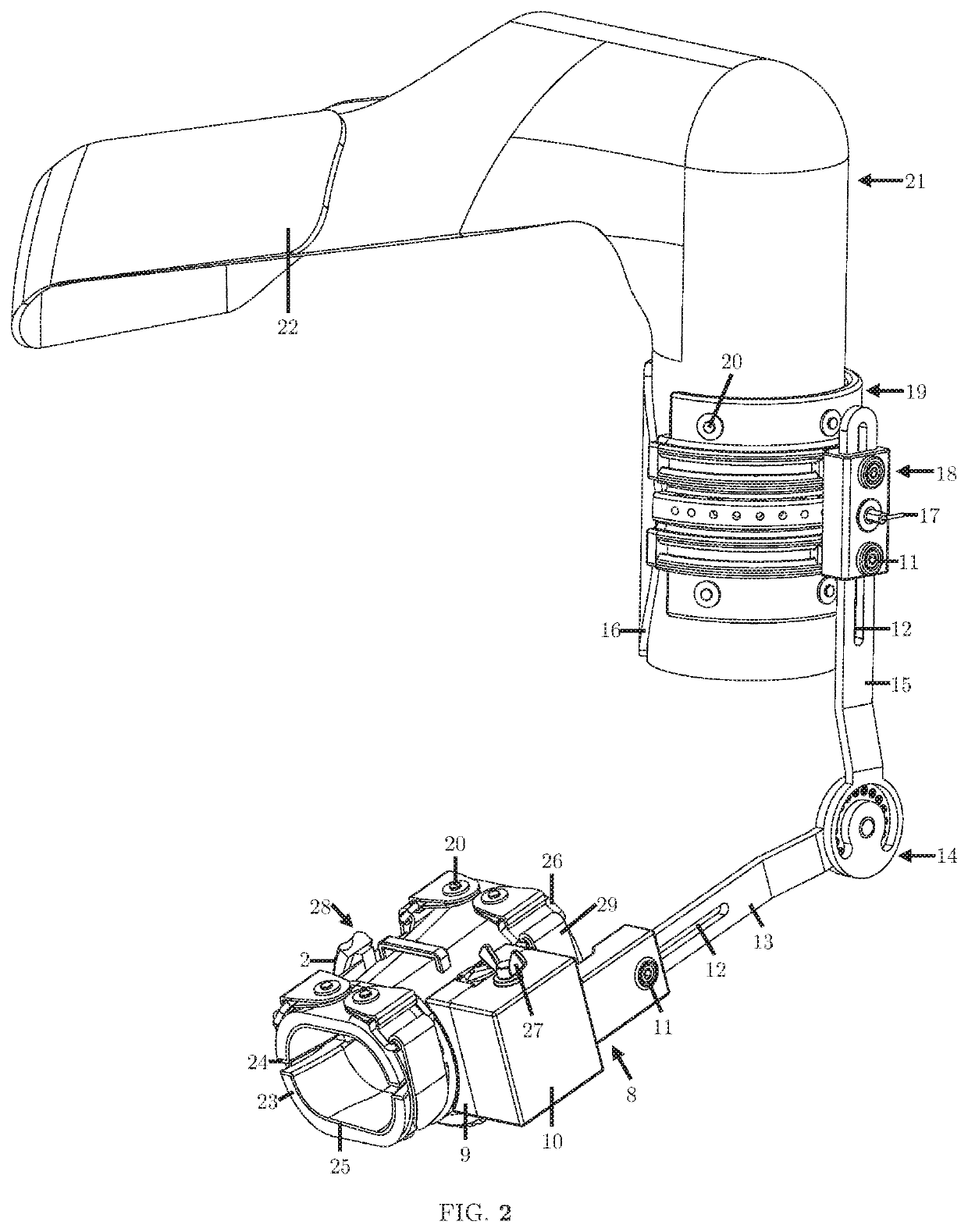

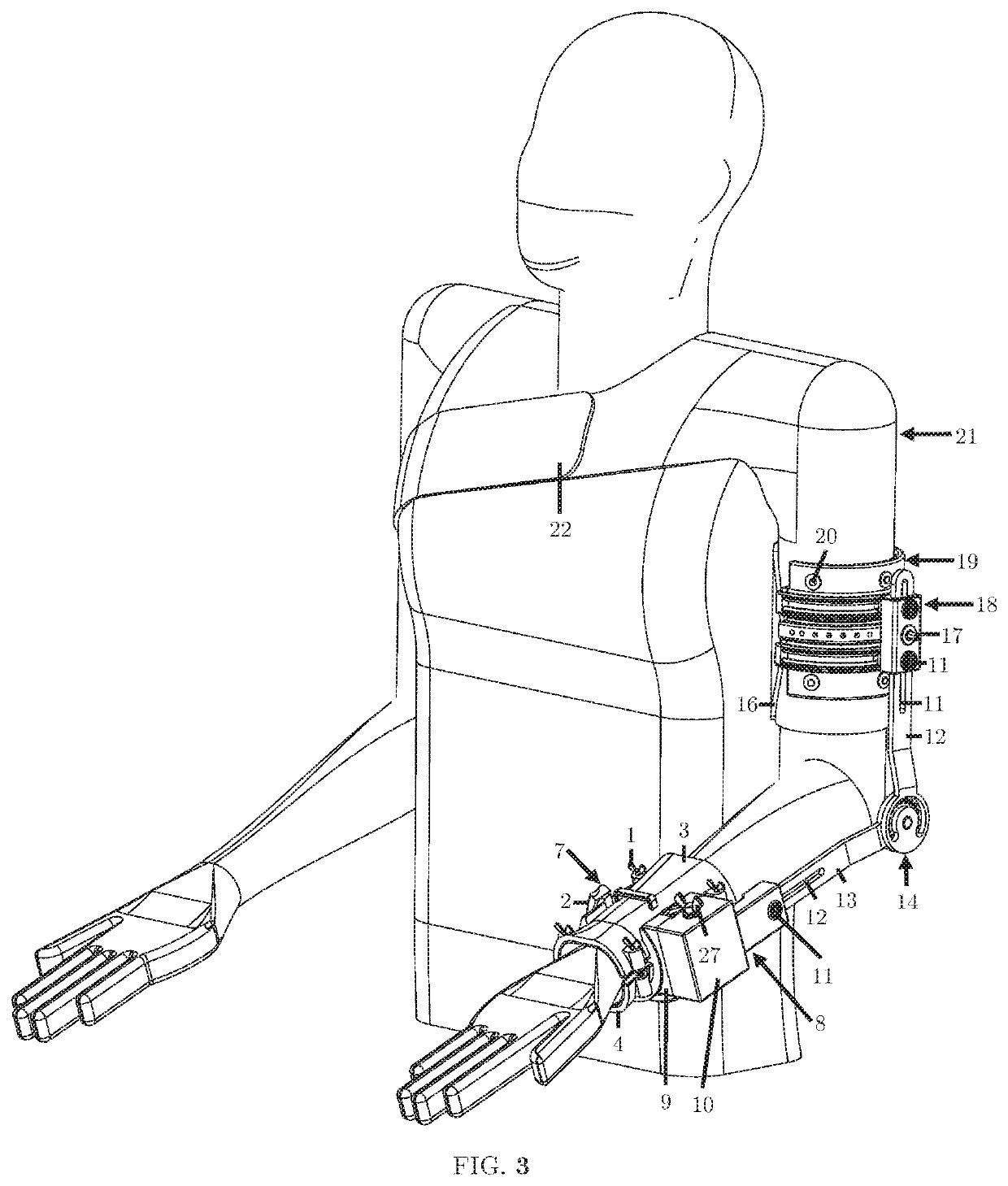

[0262]the orthosis, orthosis-ROM, is illustrated in FIG. 59. For simplicity and conciseness, it is being referred to as orthosis-ROM (where ROM stands for range of motion) because it is the embodiment that allows the arm and shoulder's full range of motion to be controlled.

[0263]Once again, for the sake of convenience, “orthosis” will be used to collectively refer to either embodiment of the orthosis, which includes orthosis-thumb, orthosis-strap, and orthosis-ROM. Similarly, “wrist cuff assembly” will be used to collectively refer to either embodiment of the wrist cuff assembly, which includes the wrist cuff assembly that uses thumbscrews, the wrist cuff assembly that uses straps, and a wrist cuff assembly that uses ratchets and pawls. The wrist cuff assembly that uses ratchets and pawls is a third embodiment that's being introduced and will be referred to as the ratchet lock wrist cuff assembly.

[0264]Referring now to the third embodiment of the present invention in more detail, in...

first embodiment

[0313]The rotary motion carriage ring 208, illustrated in FIG. 93, performs almost the same function as the linear motion carriage 54 of the orthosis of the present invention. It has the basic shape of a cylindrical shell with two diametrical steps and a shoulder 252 that is cut into the inner annulus of the side with the largest diameter step. The outside surface of the smaller step has a set of dog clutch teeth 249 that run parallel to the axis of the shell and match the geometric profile of the clutch teeth 234 on the internal-external rotation worm gear 230. Along the teeth 249 there are a number of equally-circumferentially spaced blind, threaded holes 250 whose axes are normal to the axis of the shell. Each threaded hole 250 has a ball-nose spring plunger 217 threaded into it and the ball of each plunger 217 extends slightly beyond the face of its accompanying tooth. The threaded hole 250 and the ball-nose spring plunger 217 are contemplated to use 4-48 threads but any size ma...

second embodiment

[0342]The front and rear spring rings 493, 501, illustrated in FIG. 150, have the basic shape of a cylindrical shell sector whose included angle is slightly less than the smallest included angle of the lower wrist cuff's 494“circumscribed” cylinder along its axial length. As shown in FIG. 138, this ensures that the ends do not go pass those of the “circumscribed” cylinder. The inner cylindrical surface of each ring 493, 501 has a round rail slot 563 wrapped around its perimeter that corresponds to the round rails 586 of the front and rear wrist cuff rails 522, 523, 524, 513, 514, 515. The outer cylindrical surface of each rail 493, 501 has a dovetail slot. 560 wrapped around its perimeter that corresponds to the dovetails 478 of the supination-pronation gearbox assembly 140.

[0343]The worm gear ring 506, illustrated in FIG. 151, has the basic shape of a cylindrical shell sector whose included angle is equal to that of the spring rings 493, 501. The inner cylindrical surface of the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com