Japanese paper yarn manufacturing device and japanese paper yarn manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[Schematic Configuration of Japanese Paper Yarn Manufacturing Device]

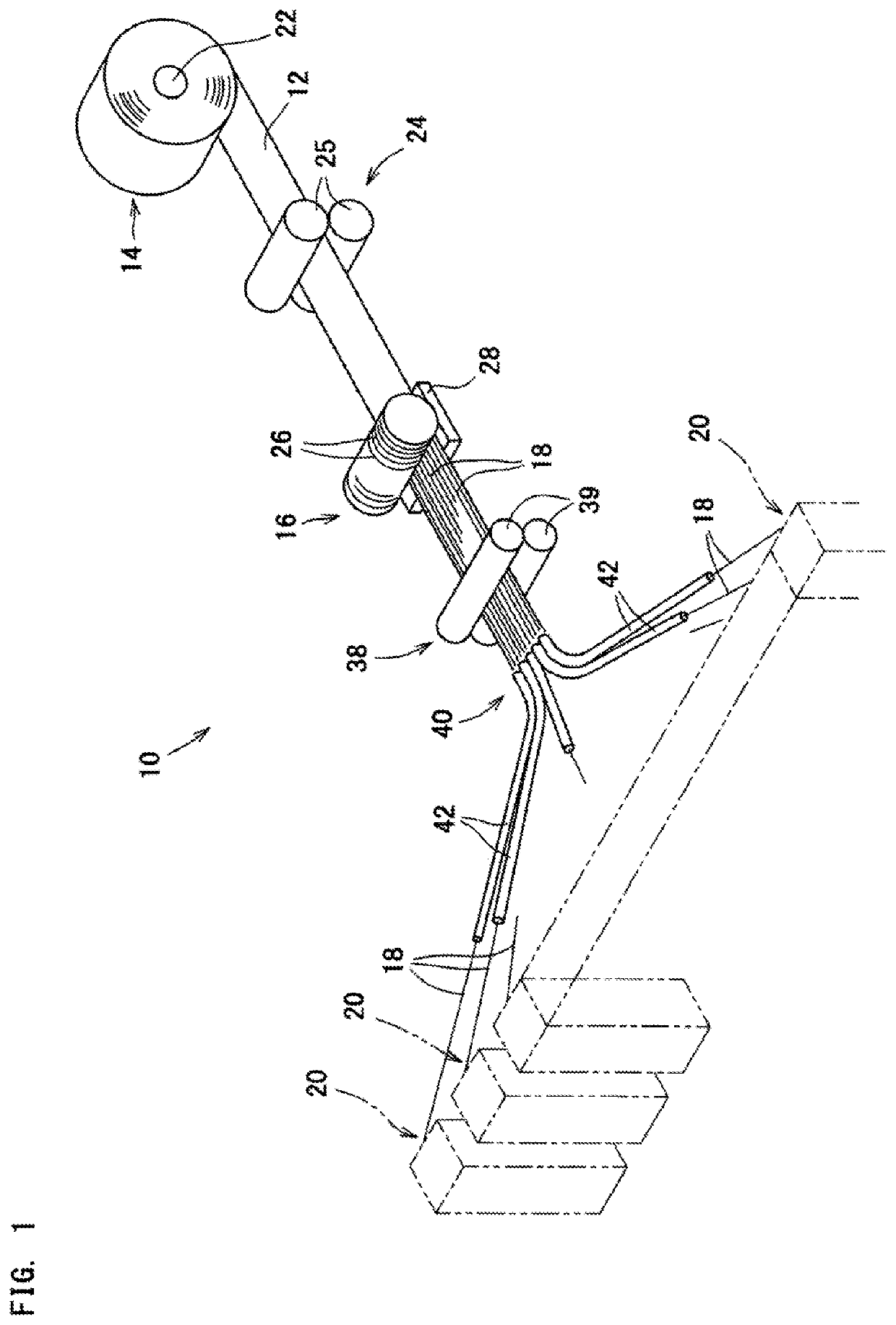

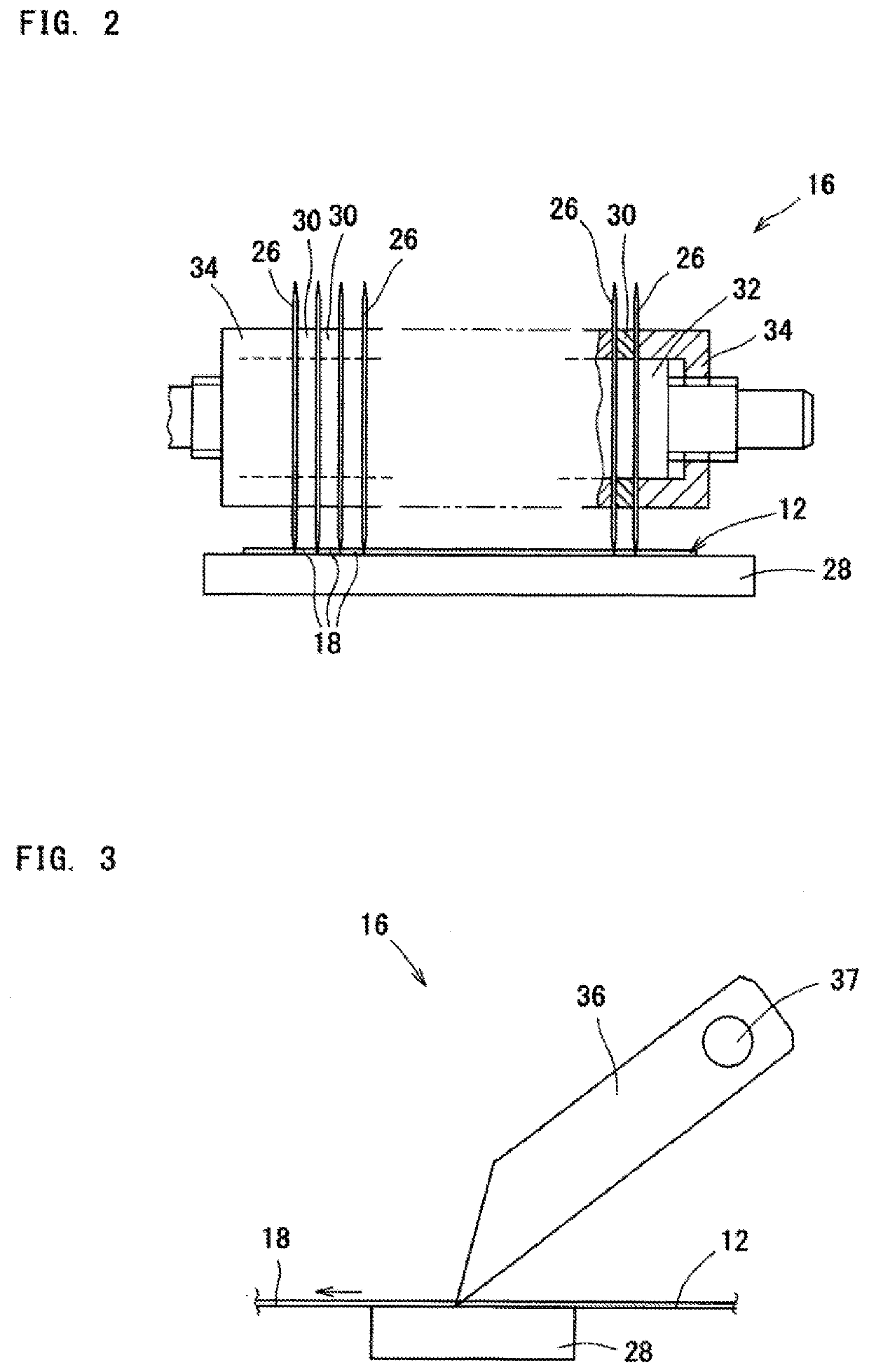

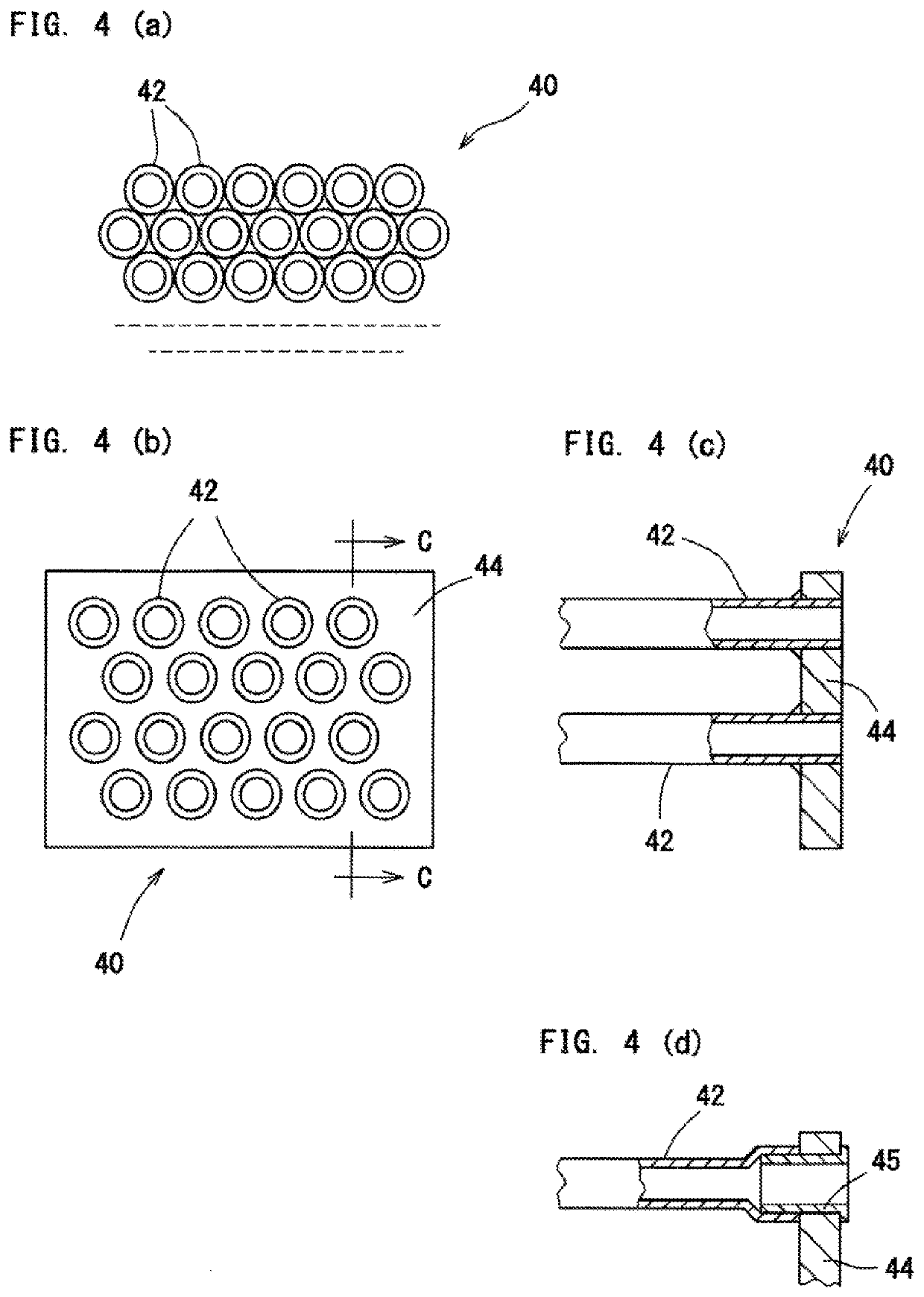

[0038]As shown in FIG. 1, a Japanese paper yarn manufacturing device 10 according to the present invention includes a Japanese paper roll 14 obtained by winding the long Japanese paper sheet 12 in a roll shape, a slitter 16 that slits the Japanese paper sheet 12 fed out from the Japanese paper roll 14 into the plurality of Japanese paper tapes in a feeding direction, the distributing section 40 provided with the plurality of tubes 42 that distributes and transports the plurality of the slit Japanese paper tapes 18 to the plurality of yarn processing device units 20 that process the Japanese paper tapes 18 into a yarn shape by twisting or covering, and the air flow section (not shown) for sending air into the plurality of tubes 42 of the distributing section 40.

[Japanese Paper]

[0039]Japanese paper used in the present invention is paper obtained by filtering a slurry form of Japanese paper raw material that mainly in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap