Positive electrode of secondary battery, and secondary battery using same

a secondary battery and positive electrode technology, applied in the direction of positive electrodes, active material electrodes, cell components, etc., can solve the problems of significant deterioration in capacity, insufficient low temperature output characteristics, and insufficient etc., to achieve excellent high temperature cycle characteristics, excellent low temperature output characteristics, and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

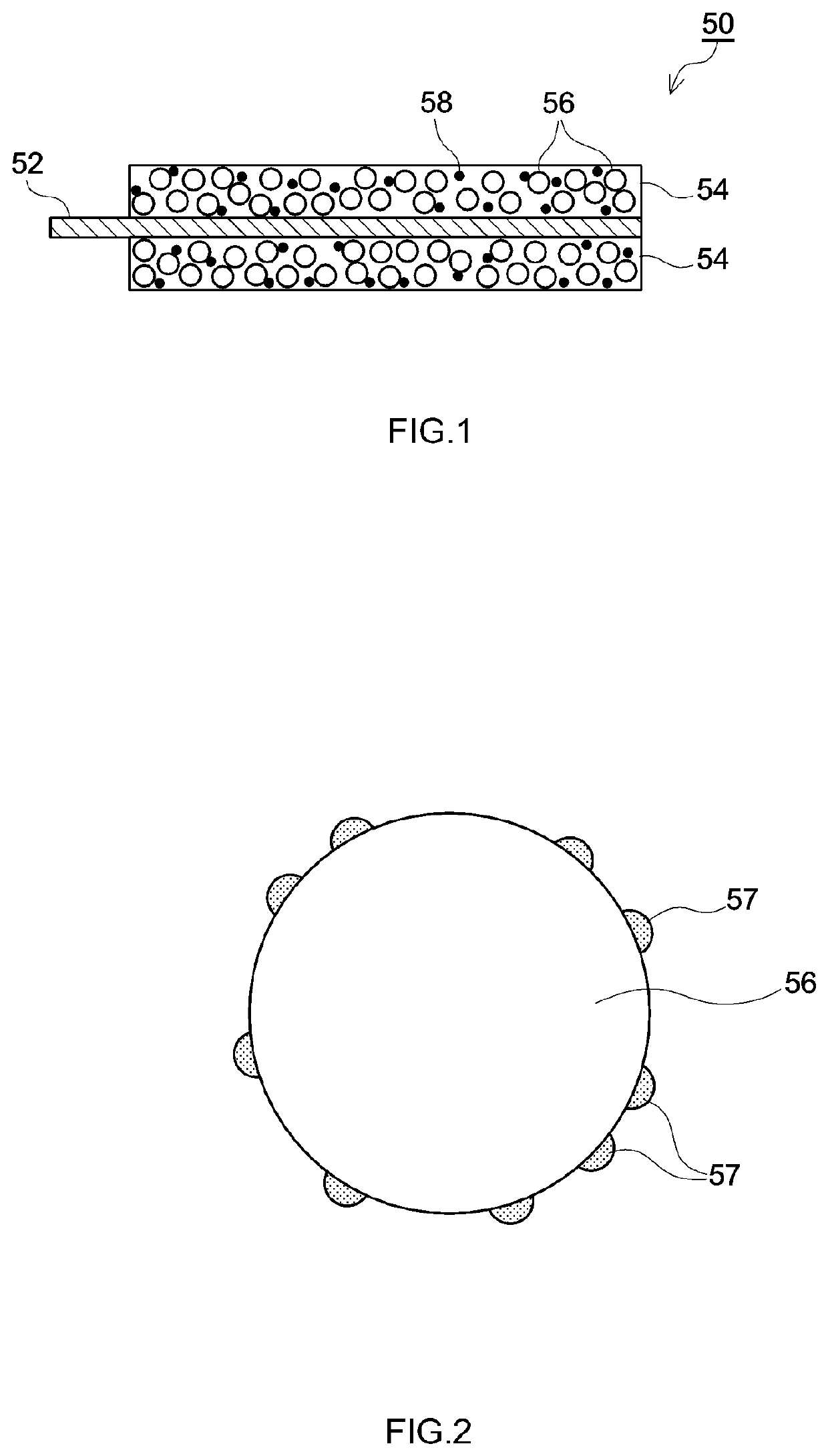

Production of Coated Particle

[0077]First, LiNi1 / 3Co1 / 3Mn1 / 3O2 particles having a layered structure were produced as positive electrode active substances in accordance with a conventional method.

[0078]Specifically, sulfates of Ni, Co and Mn were dissolved in water at a Ni:Co:Mn molar ratio of 1:1:1. By neutralizing this solution through addition of NaOH, a composite hydroxide containing Ni, Co and Mn was precipitated as a precursor of a positive electrode active substance. The obtained composite hydroxide and lithium carbonate were mixed at a molar ratio of 1:1. LiNi1 / 3Co1 / 3Mn1 / 3O2 particles having a layered structure were obtained by firing this mixture for 15 hours at a temperature of 800° C. The average particle diameter (D50) of these LiNi1 / 3Co1 / 3Mn1 / 3O2 particles was measured by means of a laser diffraction scattering method, and found to be 10 μm.

[0079]Next, the LiNi1 / 3Co1 / 3Mn1 / 3O2 particles having a layered structure were placed in a mechanochemical apparatus together with a t...

examples 2 to 36

[0091]Evaluation lithium secondary batteries were produced in the same way as in Example 1, except that LiNi1 / 3Co1 / 3Mn1 / 3O2 particles were coated with the titanium-containing compounds shown in Table 2 and oxide particles shown in Table 2 were used.

examples 37 to 45

[0092]Evaluation lithium secondary batteries were produced in the same way as in Example 1, except that a lithium-titanium composite oxide (Li / Ti atom number ratio=1) was used as the titanium-containing compound and TiO2 having the average particle diameters shown in Table 3 were used as oxide particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com