Electrolyte for non-aqueous electrolyte battery and non-aqueous electrolyte battery using same

A non-aqueous electrolyte, electrolyte technology, applied in non-aqueous electrolyte batteries, non-aqueous electrolytes, batteries, etc., can solve the problems of low temperature characteristics reduction, internal resistance increase, etc., to achieve high discharge voltage, excellent cycle characteristics, excellent low temperature Effects of Output Features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0124] As the non-aqueous electrolyte, use electrolyte No.1, LiNi 1 / 3 mn 1 / 3 co 1 / 3 o 2 Batteries were produced as the positive electrode material and graphite as the negative electrode material, and the high-temperature cycle characteristics, high-temperature storage characteristics, and low-temperature output characteristics of the batteries were actually evaluated. The test battery was produced as follows.

[0125] In LiNi 1 / 3 mn 1 / 3 co 1 / 3 o 2 5% by mass of polyvinylidene fluoride (PVDF) as a binder and 5% by mass of acetylene black as a conductive material were mixed with 90% by mass of the powder, and N-methylpyrrolidone was added to prepare a paste. This paste was applied on an aluminum foil and dried to prepare a test positive electrode body. In addition, 10% by mass of PVDF as a binder was mixed with 90% by mass of graphite powder, and N-methylpyrrolidone was further added to form a slurry. This slurry was coated on a copper foil, and dried at 150° C. for 12 ...

Embodiment 1-2~1-65

[0135] [Examples 1-2 to 1-65, Comparative Examples 1-1 to 1-64]

[0136] Electrolyte solutions No. 2 to 129 were used instead of electrolytic solution No. 1 to produce the same batteries as in Example 1-1, and the high-temperature cycle characteristics, high-temperature storage characteristics, and low-temperature output characteristics were evaluated in the same manner. The evaluation results are shown in Table 3 and Table 4.

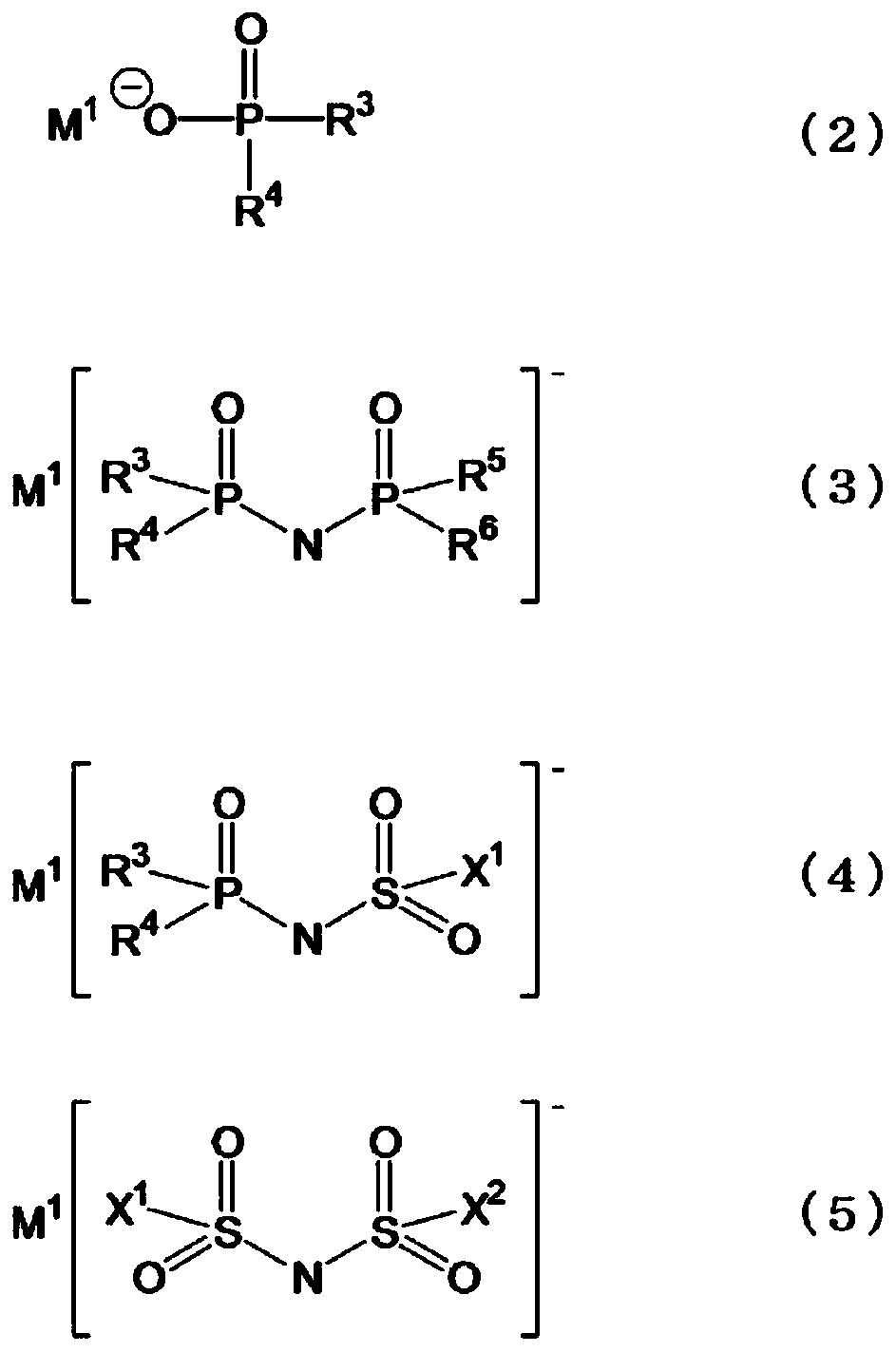

[0137] [Table 1]

[0138]

[0139] [Table 2]

[0140]

[0141] [table 3]

[0142]

[0143] *Relative value when the value of Comparative Example 1-1 is set to 100

[0144] [Table 4]

[0145]

[0146] *Relative value when the value of Comparative Example 1-1 is set to 100

[0147] Comparing the above results, it can be confirmed that by using the first compound and the second compound in combination, compared with Comparative Examples 1-2 to 1-14 using the first compound alone, it can be confirmed that the high-temperature cycle charact...

Embodiment 2-1~2-43、 comparative example 2-1~2-20

[0152] In Examples 2-1 to 2-43 and Comparative Examples 2-1 to 2-20, as shown in Table 6, except that the negative electrode body and the electrolyte solution were changed, non- Electrolyte solutions are used for aqueous electrolyte batteries, batteries are produced, and battery evaluations are performed. It should be noted that the negative electrode active material is Li 4 Ti 5 o 12 In Examples 2-1 to 2-13 and Comparative Examples 2-1 to 2-5, the negative electrode body is produced as follows: in Li 4 Ti 5 o 125% by mass of PVDF as a binder and 5% by mass of acetylene black as a conductive agent are mixed with 90% by mass of powder, and N-methylpyrrolidone is added, and the resulting paste is applied on a copper foil and dried. , the end-of-charge voltage at the time of battery evaluation was set to 2.8V, and the end-of-discharge voltage was set to 1.5V. In addition, in Examples 2-14 to 2-30 and Comparative Examples 2-6 to 2-15 in which the negative electrode active ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| face spacing | aaaaa | aaaaa |

| face spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com