Lithium secondary battery including non-aqueous electrolyte solution

a secondary battery and lithium battery technology, applied in the direction of cell components, sustainable manufacturing/processing, final product manufacturing, etc., can solve the problems of difficult to expect the improvement of low-temperature output characteristics, degraded high-temperature storage performance and life performance of batteries, etc., to achieve excellent low-temperature output characteristics and improve high-temperature storage characteristics and life characteristics. , the effect of improving the quality of li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

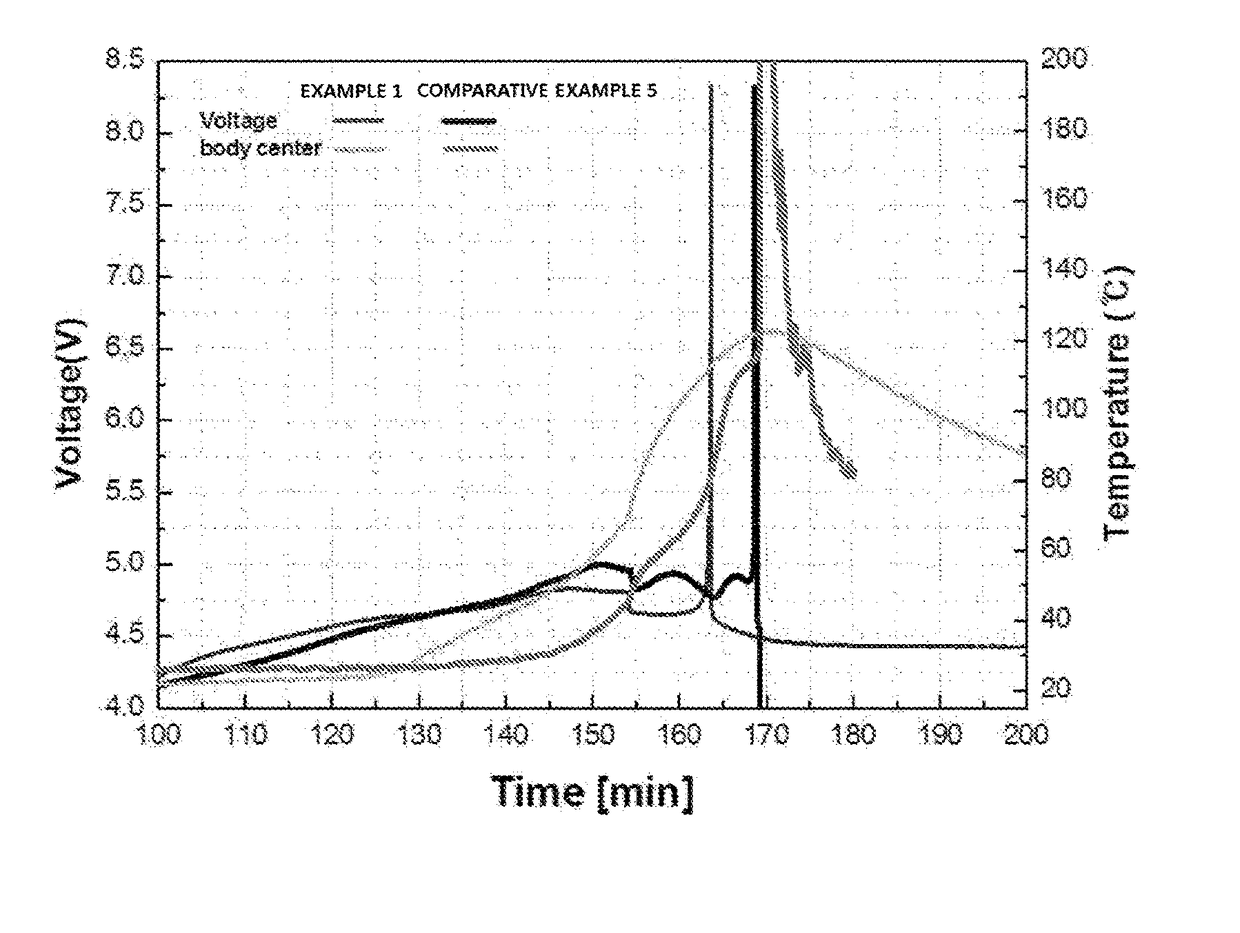

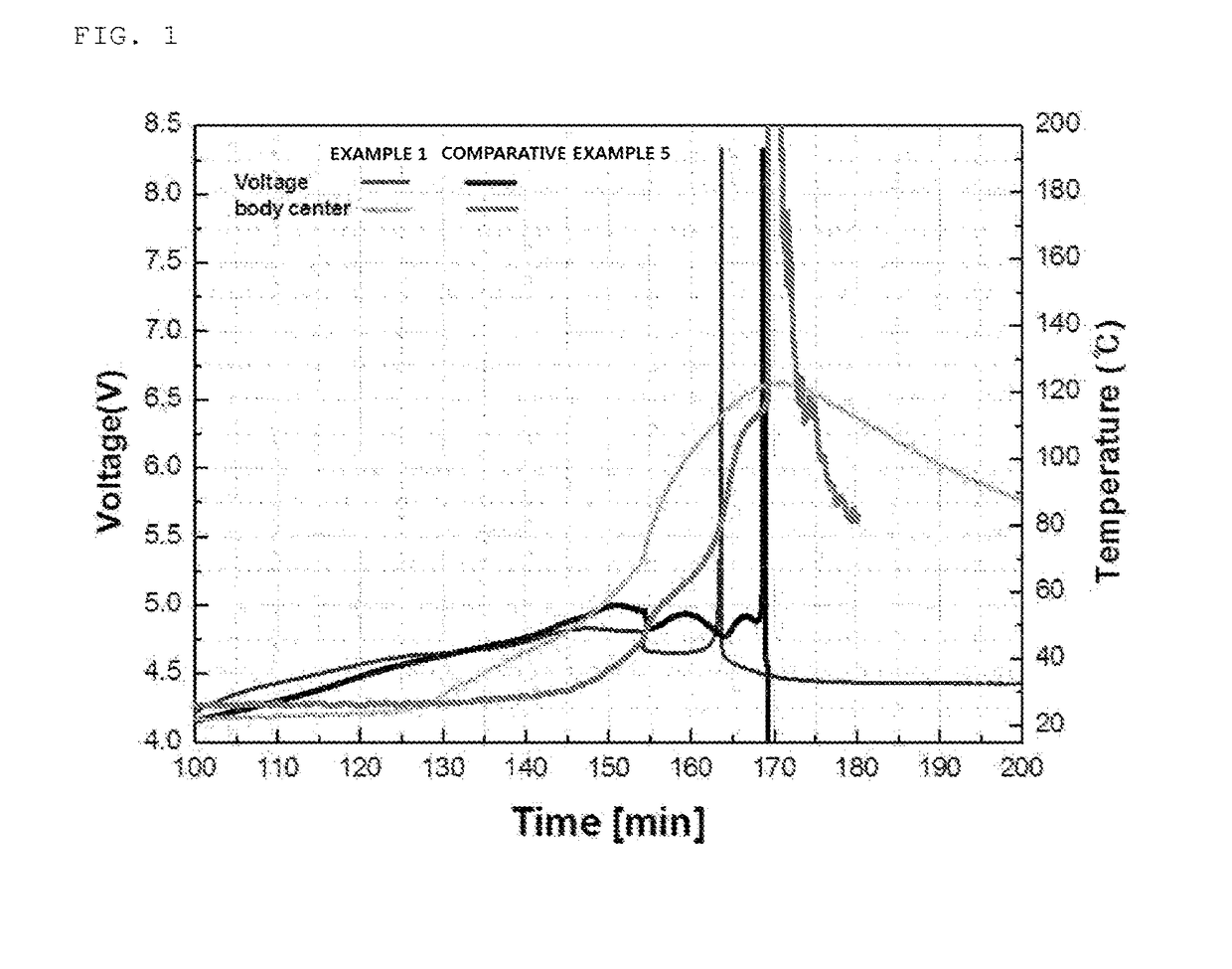

example 1

[0044][Preparation of Electrolyte Solution]

[0045]A non-aqueous electrolyte solution was prepared by adding 0.9 mol / L of LiPF6, as a lithium salt, based on a total amount of the non-aqueous electrolyte solution and adding 0.1 mol / L of lithium bis(fluorosulfonyi)imide and 3 wt % of 2,3-difluorobiphenyi to a non-aqueous organic solvent having a composition in which a volume ratio of ethylene carbonate (EC):ethylmethyl carbonate (EMC) was 3:7.

[0046][Preparation of Lithium Secondary Battery]

[0047]A positive electrode mixture slurry was prepared by adding 92 wt % of Li(Ni0.6Co0.2Mn0.2)O0.2)O2 as a positive electrode active material, 4 wt % of carbon black as a conductive agent, and 4 wt % of polyvinylidene fluoride (PVdF) as a binder to N-methyl-2-pyrrolidone (NMP) as a solvent. An about 20 μm thick aluminum (Al) thin film as a positive electrode collector was coated with the positive electrode mixture slurry and dried, and the coated Al thin film was then roll-pressed to prepare a positi...

example 2

[0050]A non-aqueous electrolyte solution and a lithium secondary battery were prepared in the same manner as in Example 1 except that 0.7 mol / L of LiPF6 and 0.3 mol / L of lithium bis(fluorosulfonyl)imide were used.

example 3

[0051]A non-aqueous electrolyte solution and a lithium secondary battery were prepared in the same manner as in Example 1 except that 0.5 mol / L of LiPF6 and 0.5 mol / L of lithium bis(fluorosulfonyi)imide were used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com