Closed loop energy production from producing geothermal wells

a geothermal well and closed-loop technology, applied in indirect heat exchangers, machines/engines, lighting and heating apparatus, etc., can solve the problems of high cost of hydrothermal well drilling success, high cost of hydrothermal resources, and high cost of locating appropriate hydrothermal resources, so as to reduce the potential of steam condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

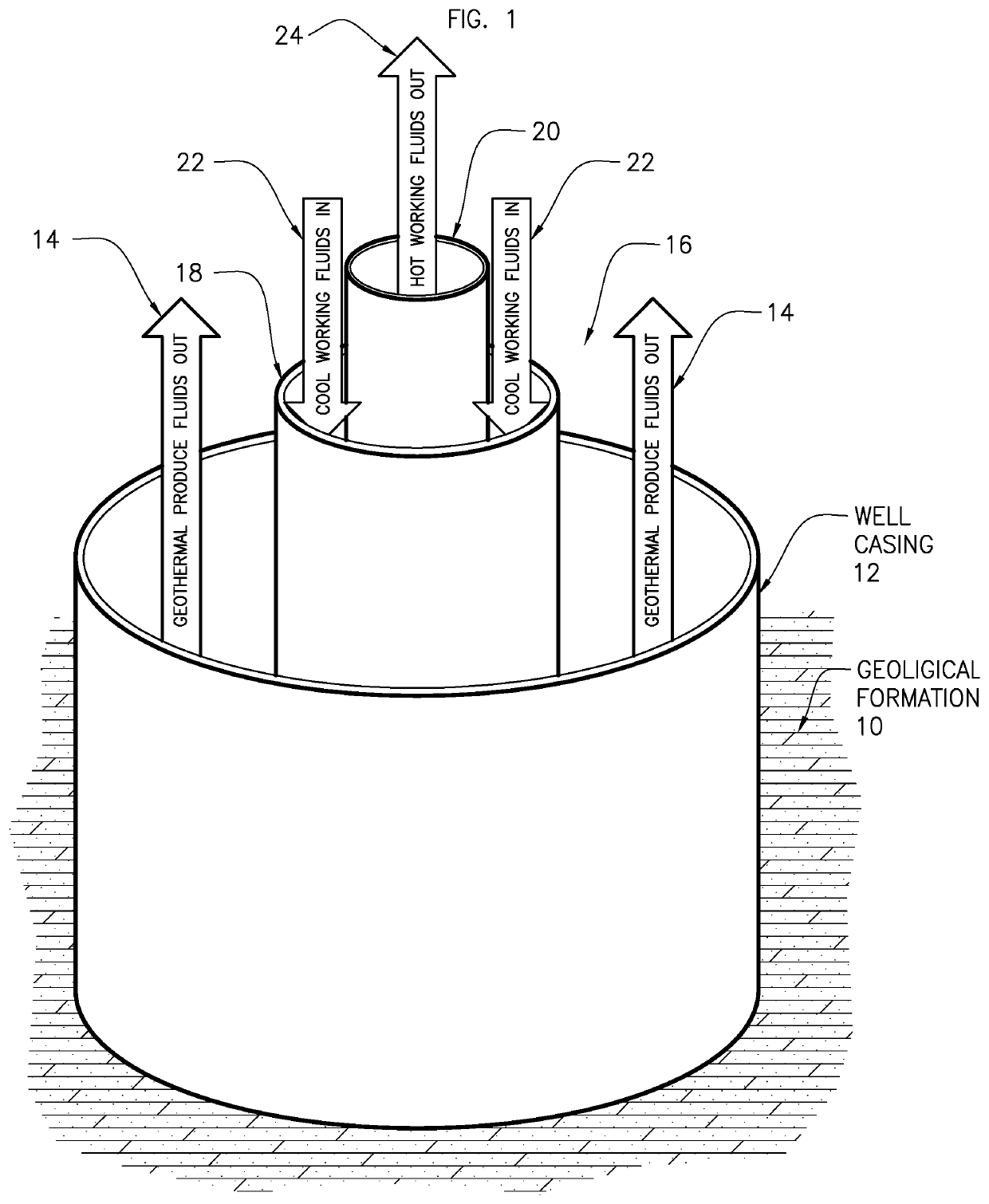

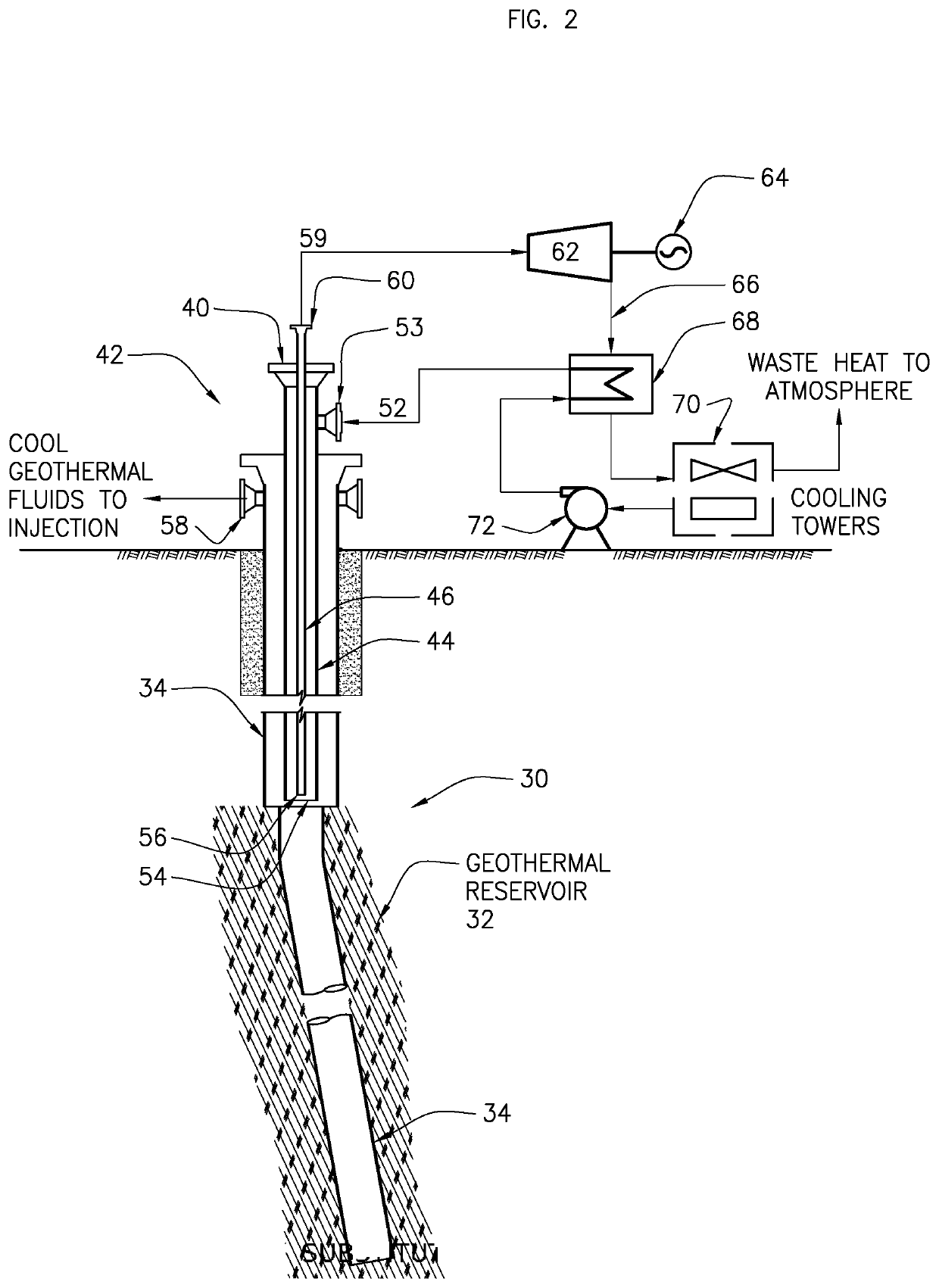

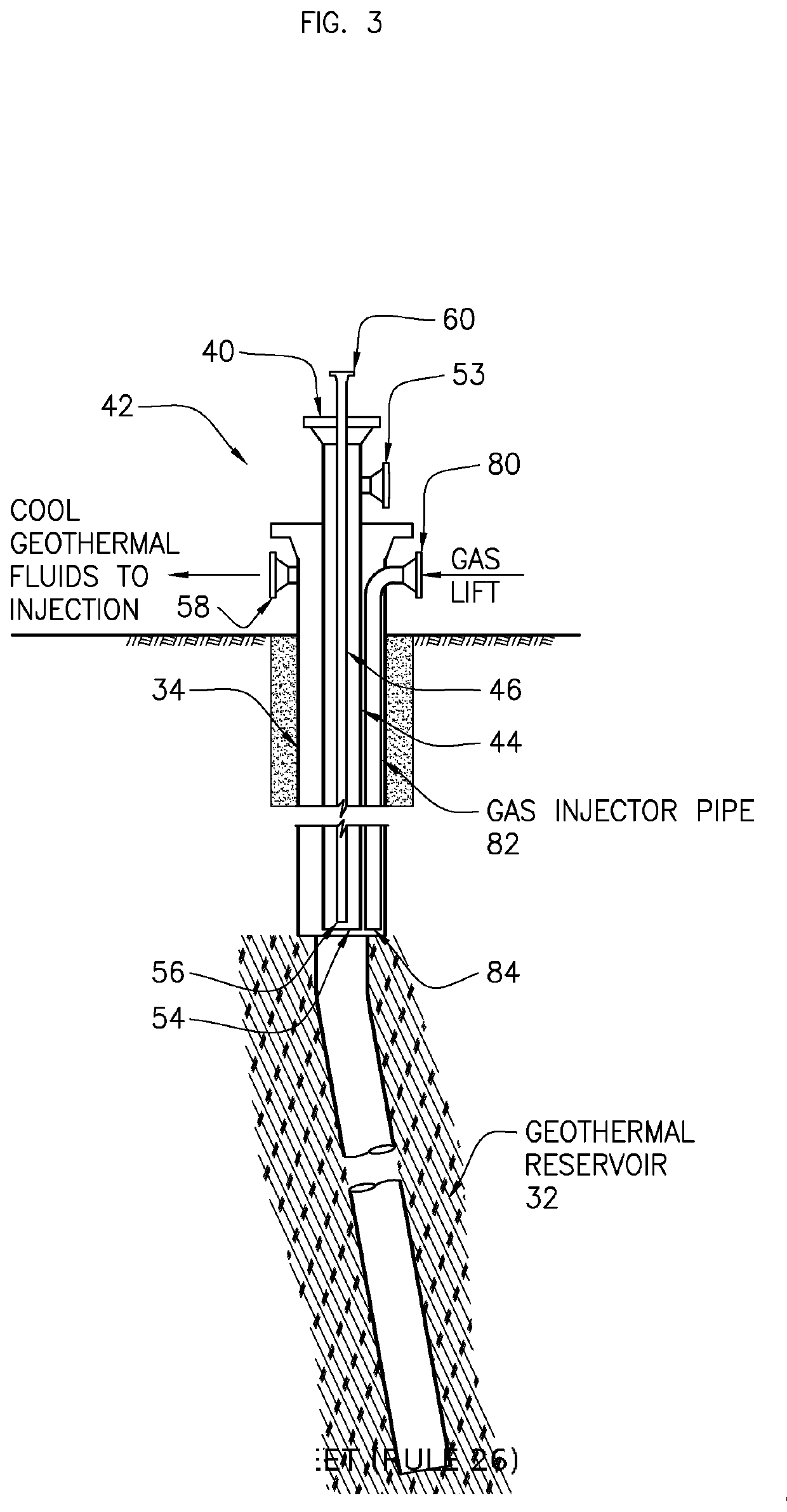

[0032]In a geothermal reservoir, the hot fluids are generally under tremendous pressure, the source of this pressure being the rock overburden (lithostatic pressure), the water table (hydrostatic pressure), or some combination of the two. As geothermal fluid comprised of steam and / or brine is produced from a geothermal reservoir via a well, it undergoes a reduction in pressure. Indeed, this pressure difference is what propels the geothermal steam or brine to the surface. Depending on the pressure and the enthalpy of the steam or brine, it may expand or flash to a vapor as it rises up the well. While this does not adversely affect the enthalpy of the produced fluid, it does result in a decreased temperature of the produced mixture of steam and brine. If a heat exchanger only at the surface is used to transfer this heat into a separate working fluid, as is typically used in binary systems, the working fluid cannot be made hotter than the brine and steam temperature at the surface. Thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com