Thermosplastic vulcanizates from blends of a polypropylene and elastic alpha -olefin/cyclic olefin copolymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

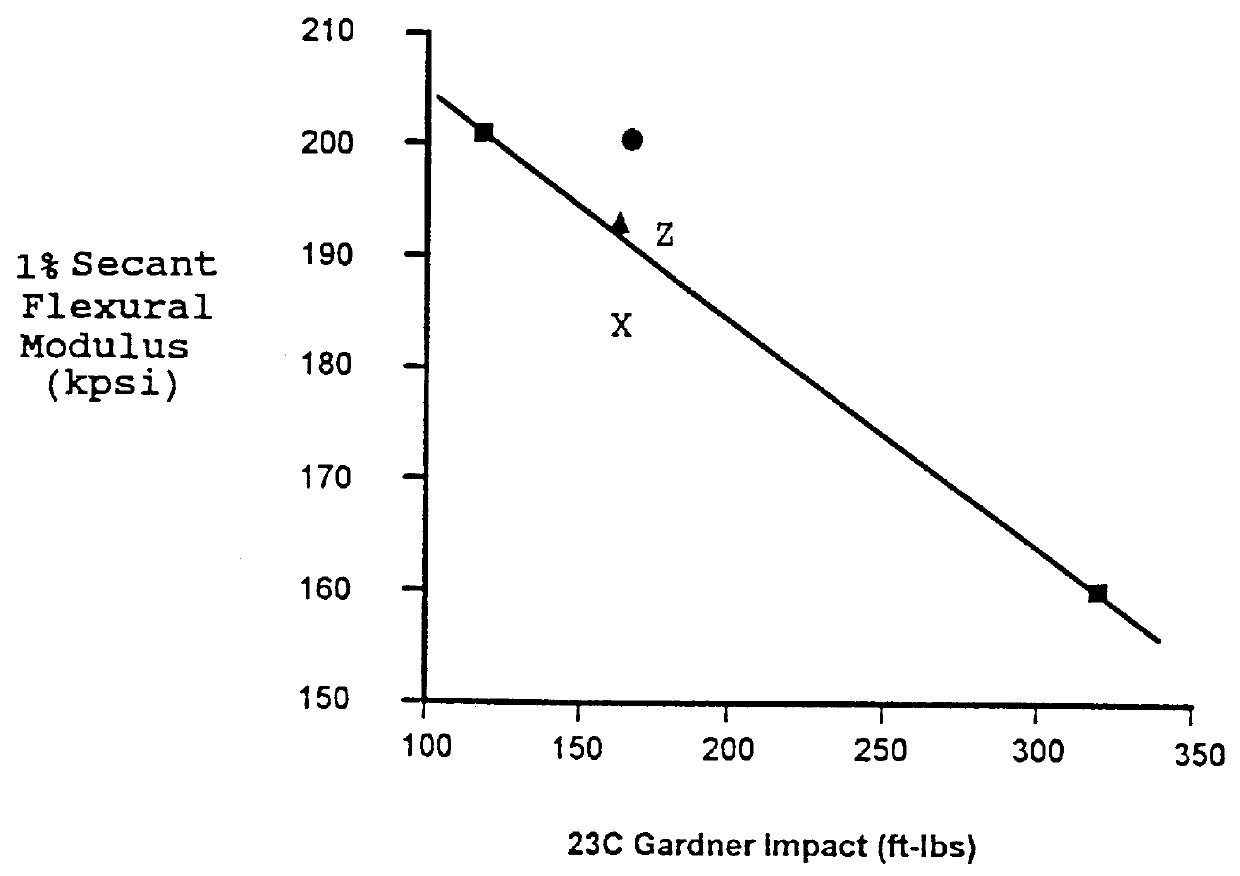

Image

Examples

example 2

Several blends, A-H, were physically mixed using a Brabender Counter rotating mixer using the small mixing head (45 ml). Mixing conditions were as follows:

The head was preheated to 190.degree. C. for 5 minutes. A manually blended mixture was fed into the mixing chamber with screws rotating at 60 rpm. The mixture was blended for 5 minutes and then removed. The blends were then compression molded. The blends and the test data are reported in Table 2.

Several blends (M-T) were mixed and pelletized using two passes through a single screw extruder with a 200 mesh screen pack. The pellets were injection molded into test pieces.

The copolymers were selectively tested for norbornene content by carbon nuclear magnetic resonance (CNMR) and / or proton NMR (.sup.1 HNMR); molecular weight (M.sub.w) and molecular weight distribution (M.sub.w / M.sub.n) by gel permeation chromatography; and glass transition temperature (T.sub.g) by differential scanning calorimetry (DSC) using ASTM E 1356. The DMTA wa...

example 3

11.6 of PP4 was physically admixed with 11.6 g of ENB3 then poured into a preheated Brabender with 0.1201 g of di-t-butyl peroxide (98.5 % pure). The components were blended for ten minutes at 190 C. using a small 45 g mixing head. The cured blend was then tested for physical properties. The data for the cured blend, one uncured blend and neat polypropylene are summarized in Table 5.

The data show that the rubbery thermoplastic copolymer will crosslink to improve the toughness of the blends to such an extent that they are competitive in properties with commercial reactor thermoplastic olefins. The instant blends are different however because the rubbery thermoplastic copolymer has a higher packing length than the semi-crystalline polymer causing it to be excluded from the surface. Packing length is defined and measured or calculated in Fetters, L. J., Lohse, D. J. Richter, D., Witten, T. A., and Zirkel, A. Macromolecules, 1994 incorporated by reference herein. After crosslinking the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com