Composite lawn edging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

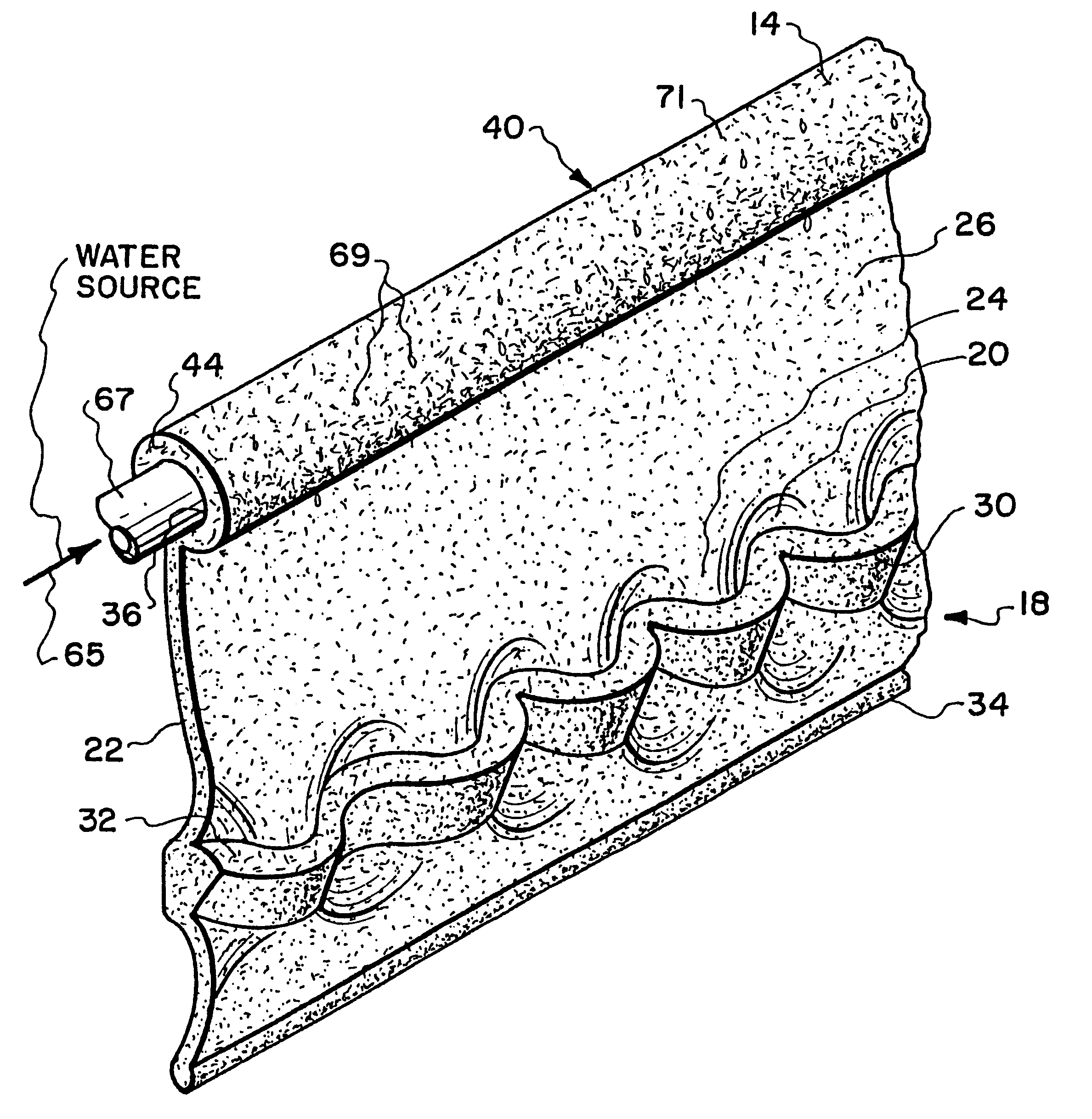

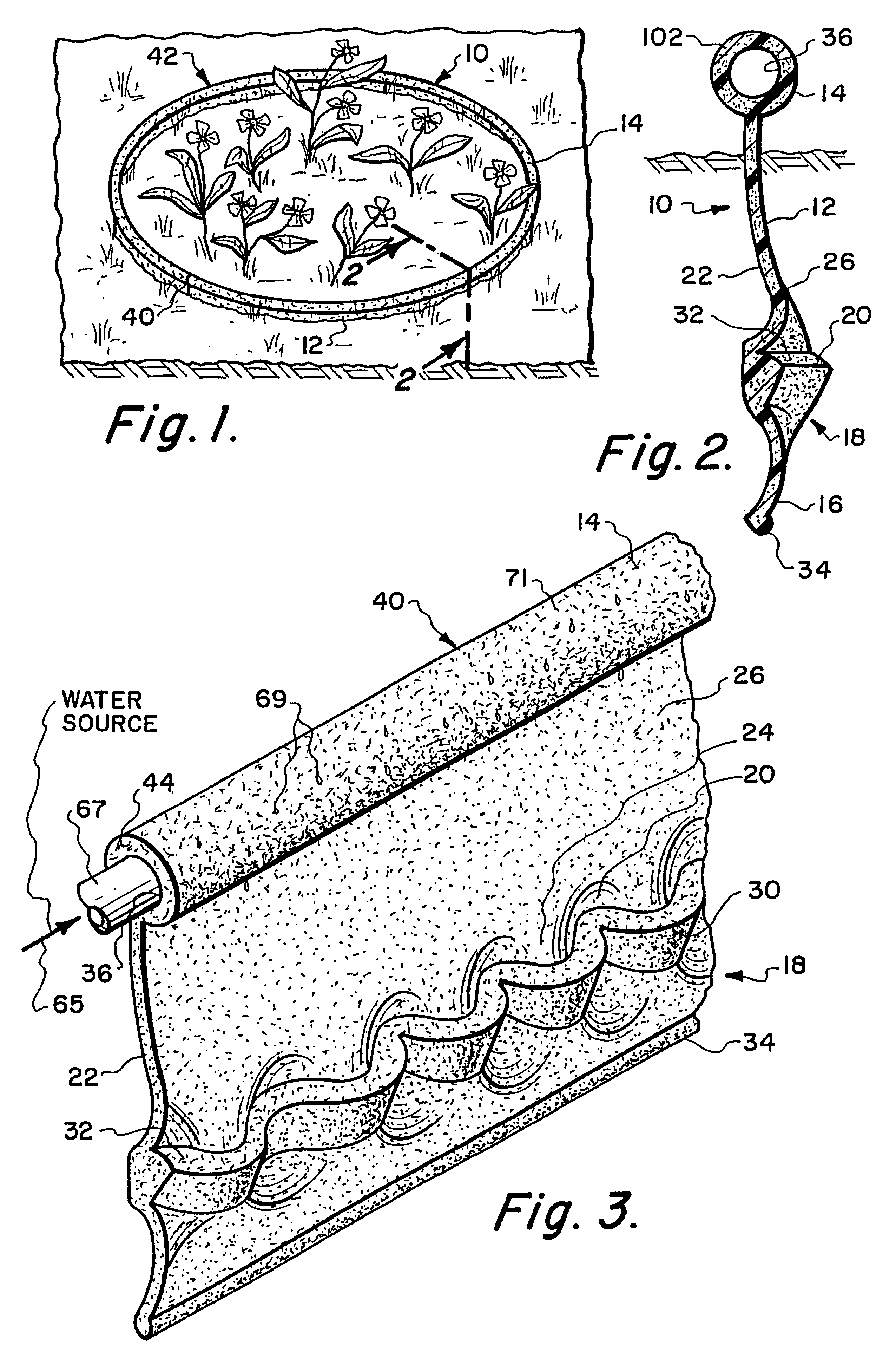

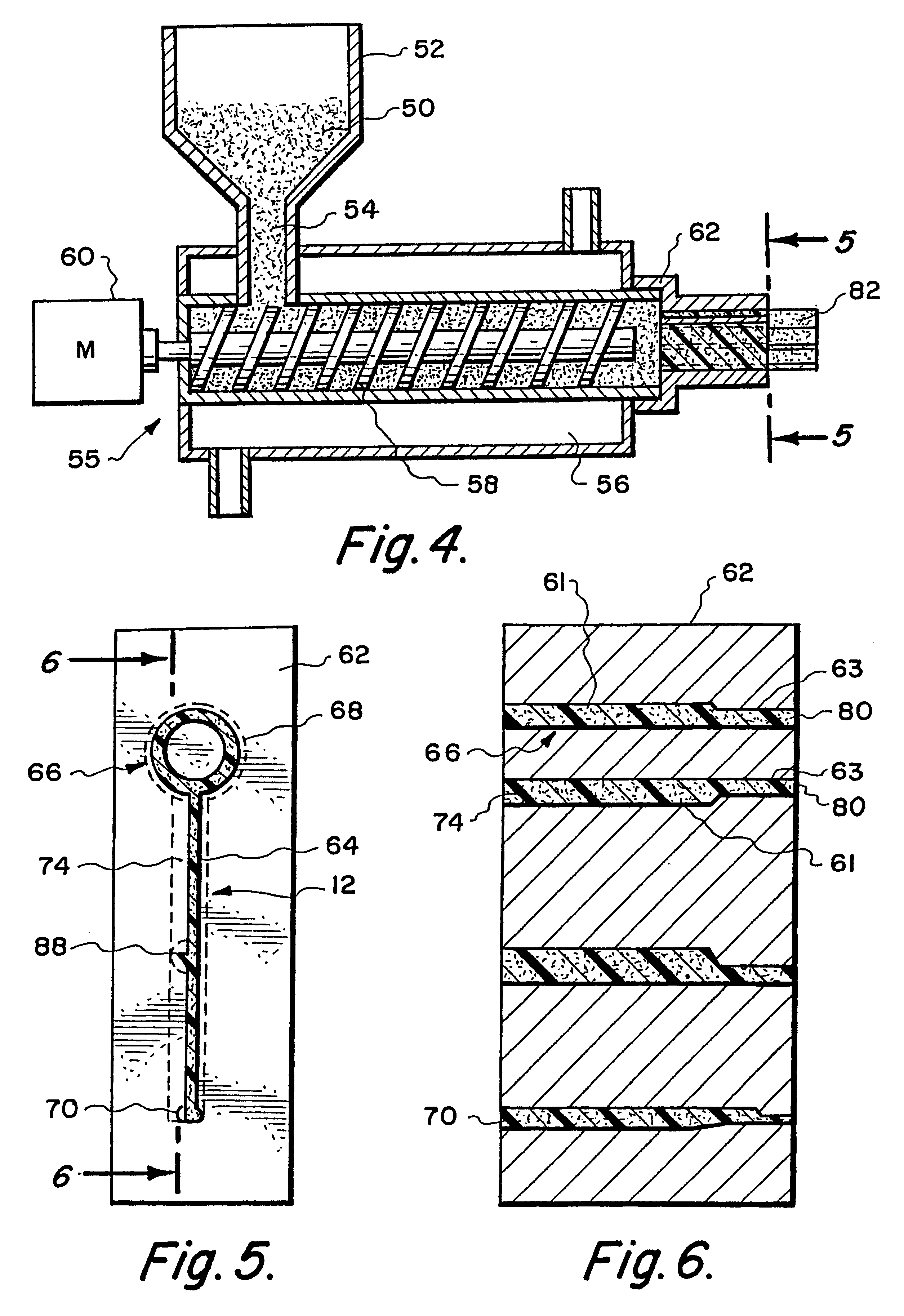

A lawn edging was prepared from a mixture of 50 percent by weight of 30 mesh vulcanized rubber particles from tires and 50 percent linear, low density polyethylene pellets. The particles and pellets were mixed. The mixture was fed to a vented twin screw extrude heated to a temperature of 380.degree. F. The die was heated to a temperature from 360.degree. F. to 380.degree. F. As the mixture was extruded through a die orifice as shown in FIG. 5, lawn edging as depicted in FIGS. 2 and 3 was extruded.

The lawn edging was tested for bending and was substantially more flexible than commercial polyethylene lawn edging. The composite lawn edging was easily planted into a curved trench and showed no tendency to creep up out of the ground.

Further aspects of the invention are illustrated in FIG. 7. The lawn edging 10 formed from a rubber-thermoplastic resin is usually porous. Since the enlarged head 14 can be in hollow pipe form, it can be used as a drip emitter. When fitting 67 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com