Thermo-electric cooler for use in an optical assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Embodiments of the present invention are described below by way of example only. These examples represent the best ways of putting the invention into practice that are currently known to the Applicant although they are not the only ways in which this could be achieved.

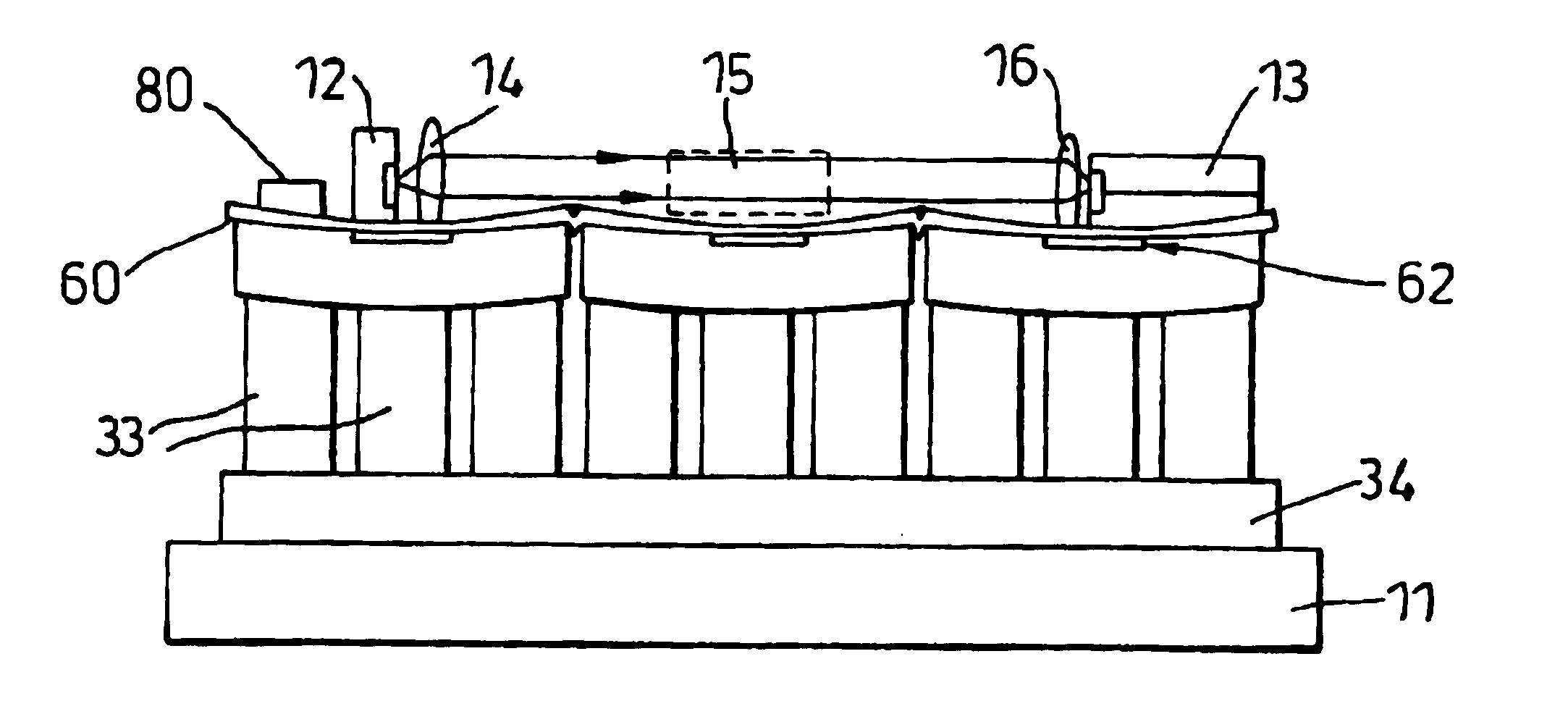

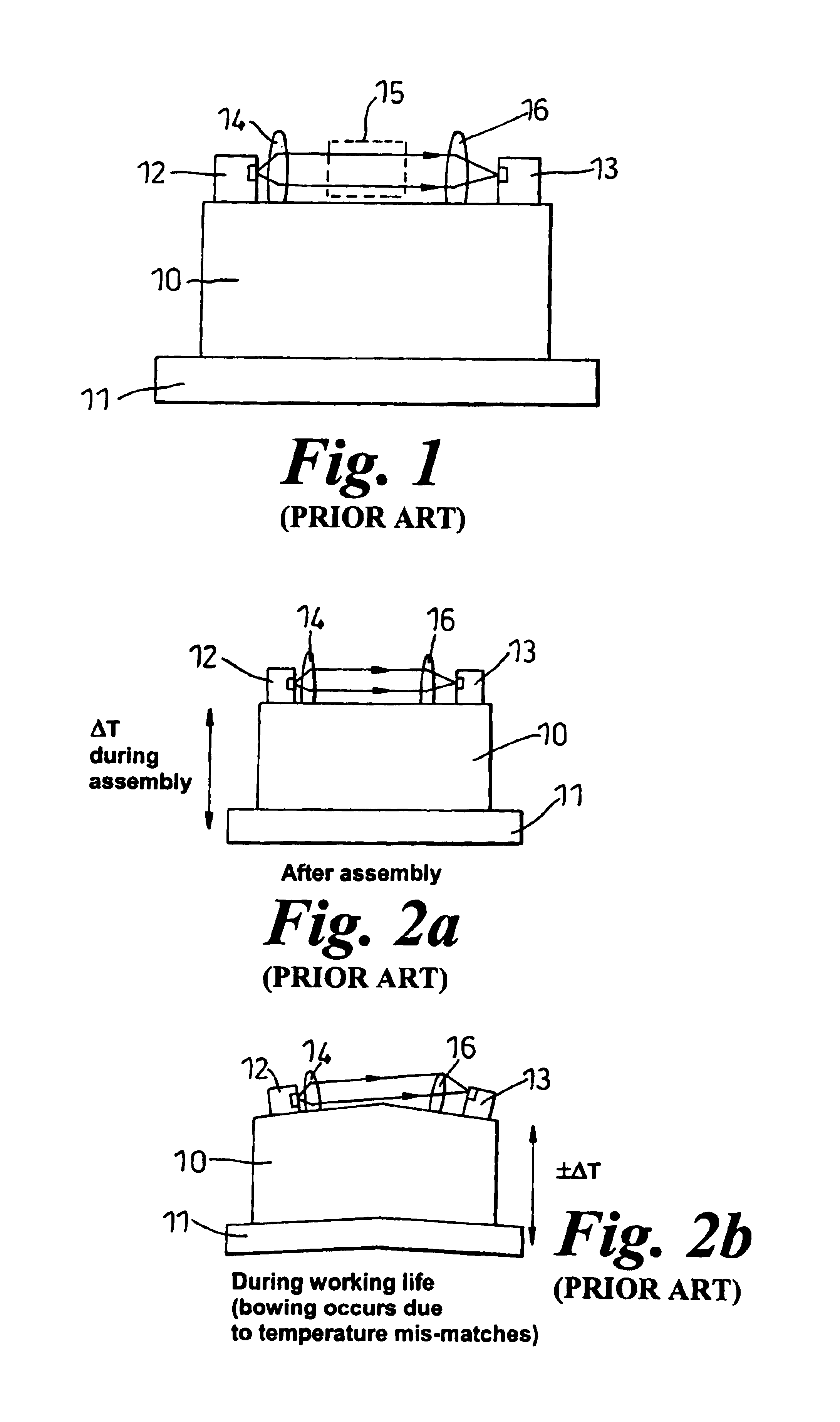

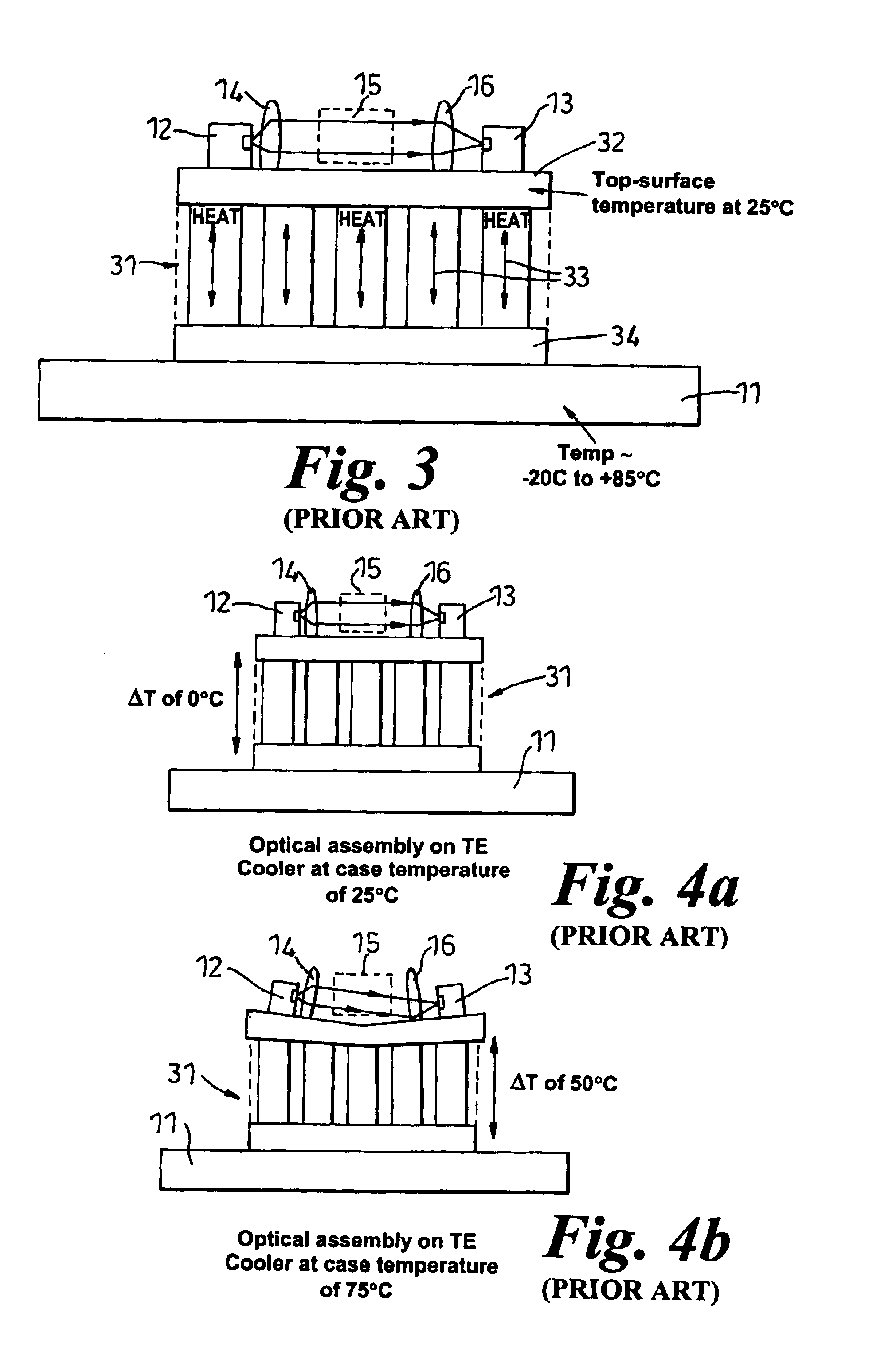

FIG. 1 is a schematic cross-section through a free-space optical train according to the prior art. An optical bench comprising a block of silica 10 rests inside a package or case 11. The optical bench supports a free-space optical train comprising a laser 12, two collimating lenses 14, 16, an optical gadget 15 (which may be any suitable device such as a beam splitter or isolator) and a waveguide 13. These components are arranged in series along an upper surface of the optical bench as illustrated in FIG. 1.

An aim for such free-space optical systems is to ensure maximum light or power coupling efficiency between each component in the optical train. Typically, lenses are used to alter the dimensions of the wavefront to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com