Automatic calibration method for engine misfire detection system

- Summary

- Abstract

- Description

- Claims

- Application Information

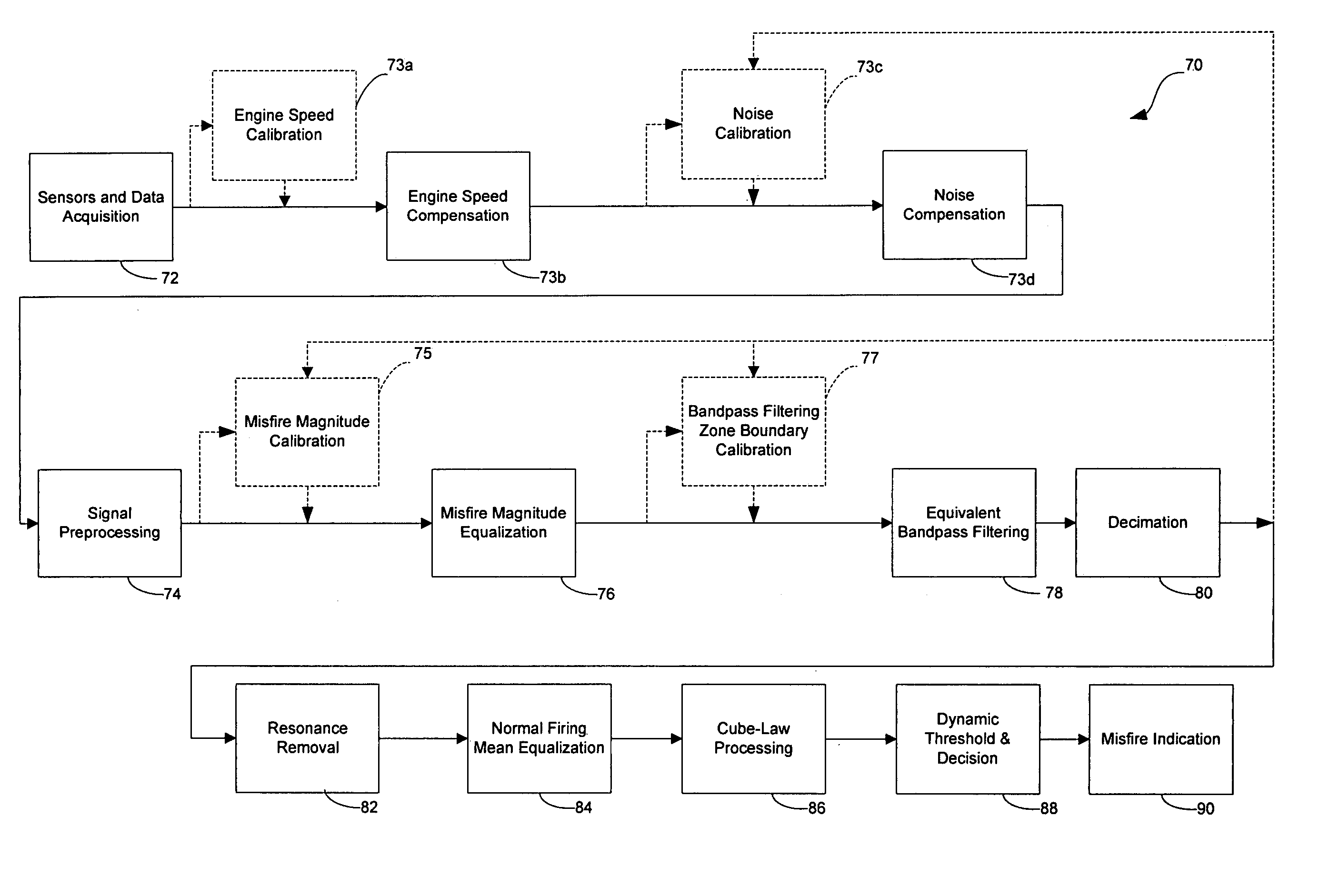

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The following description of the preferred embodiment(s) is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses.

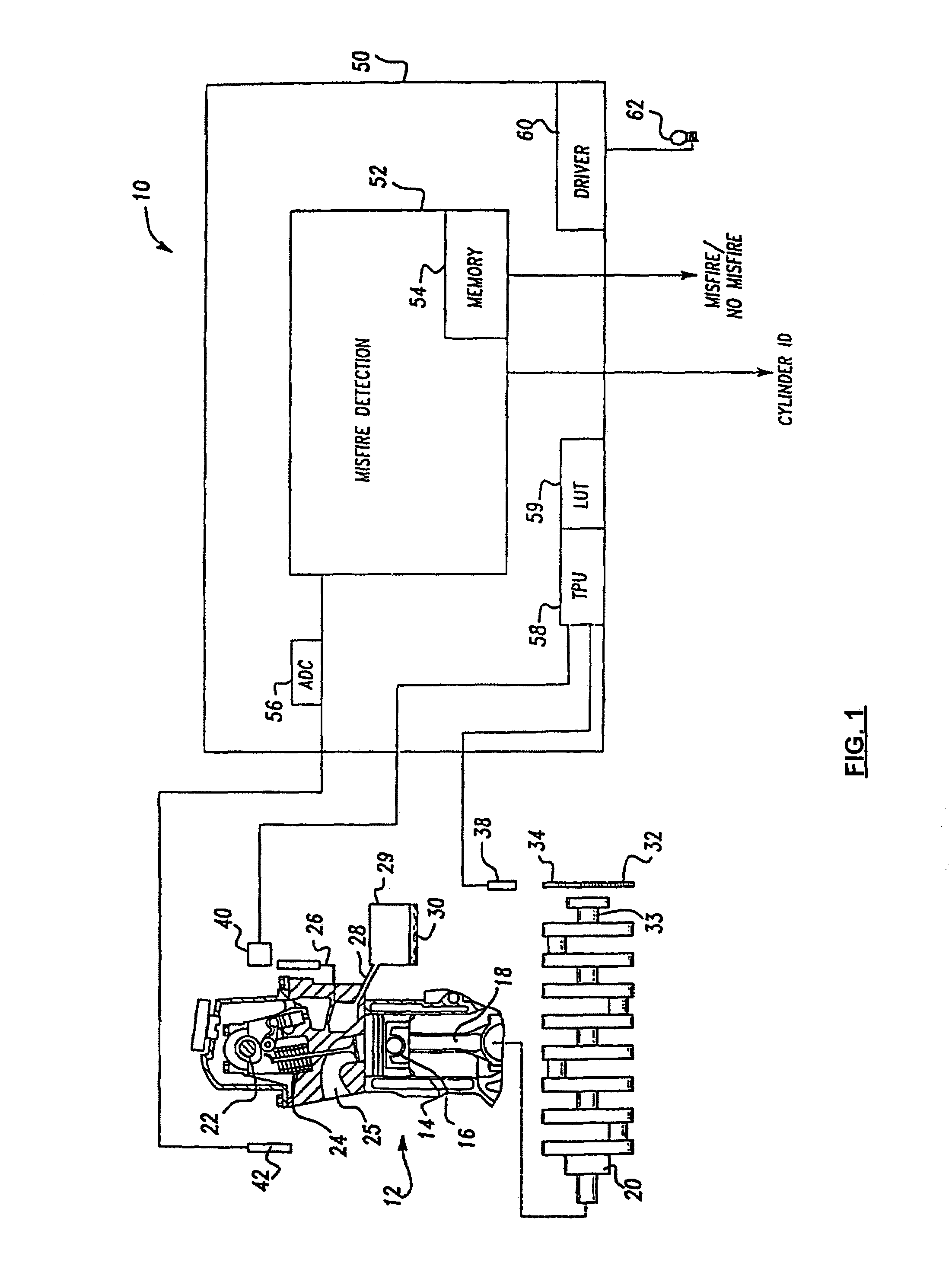

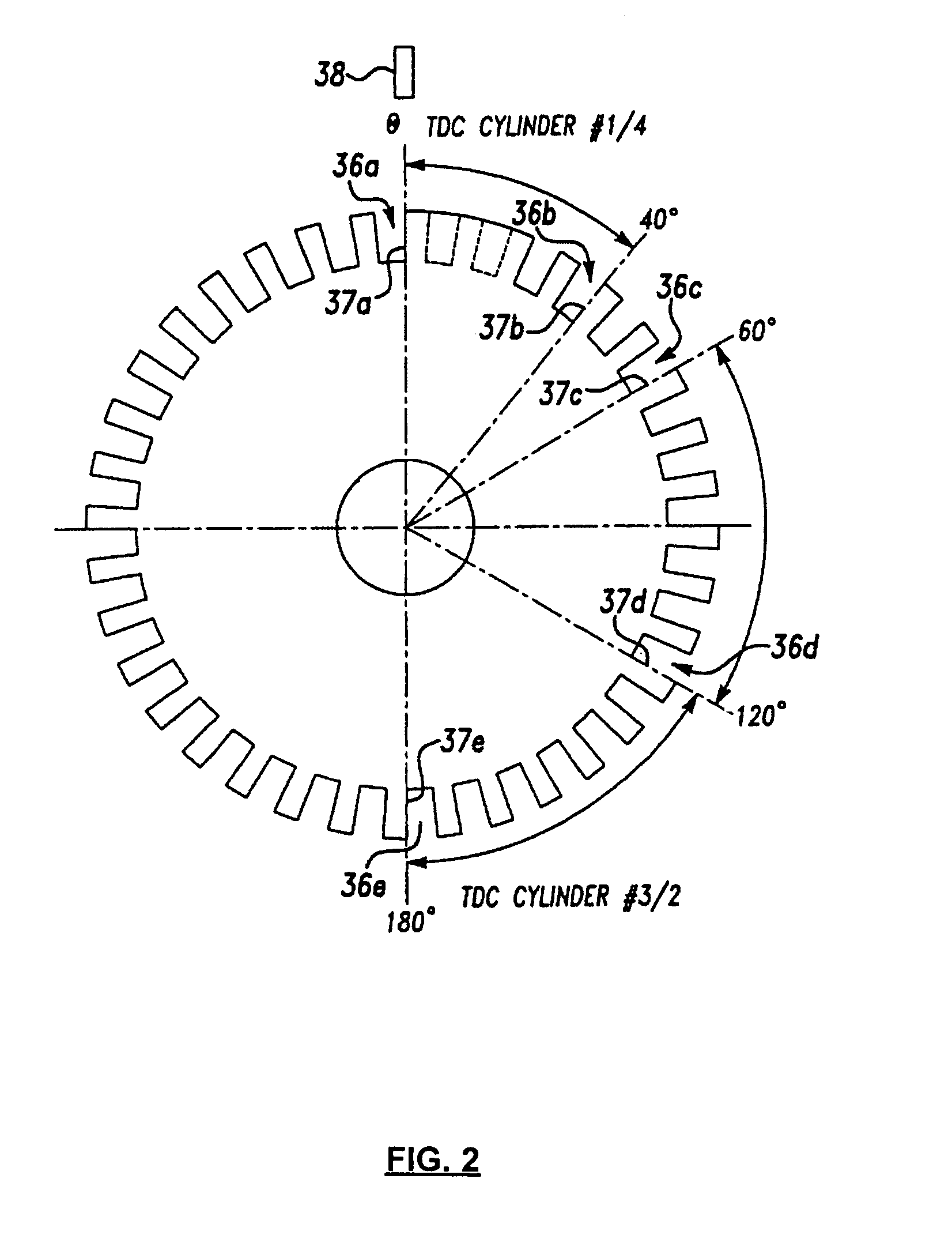

[0032]Referring now to the FIG. 1, a block diagram of the engine system, in which the misfire detection system calibrated by the system of the present invention is implemented, is shown generally at 10. The system 10 includes an internal combustion spark ignited engine 12, shown in partial cross-section, which is of the type implemented in a conventional motor vehicle (not shown). The engine contains a plurality of cylinders, represented by the cylinder 14, with each of the cylinders having a piston, represented by the piston 16, operatively disposed therein. Each of the pistons is connected by a connecting rod 18 to a crankshaft 20. A conventional engine cam shaft 22 is also operatively located within the engine for opening and closing intake and exhaust valves, such as the intake valve 24, associated with the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com