Internal combustion engine controller

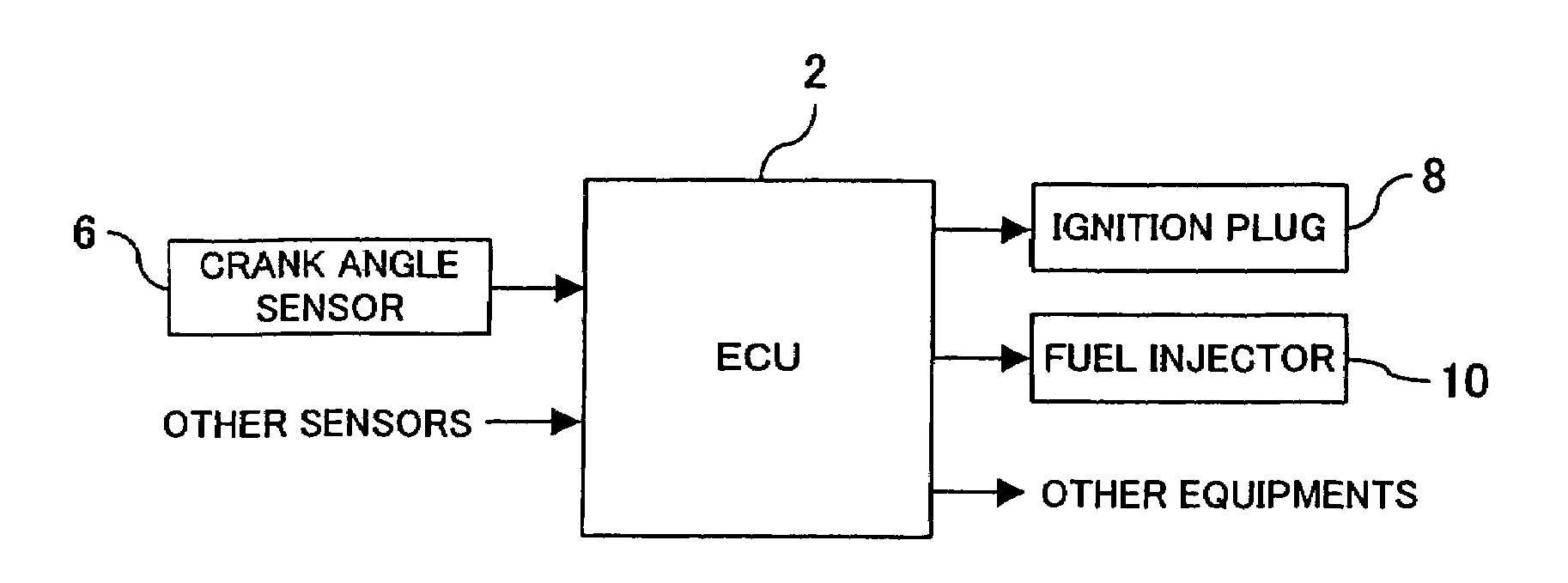

a technology of internal combustion engine and controller, which is applied in the direction of electric control, ignition automatic control, instruments, etc., can solve the problems of unstable idle revolving speed, technology delay in ignition timing, and incur vibration, so as to minimize the degree of combustion status variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0033]A first embodiment of the present invention will now be described with reference to the accompanying drawings.

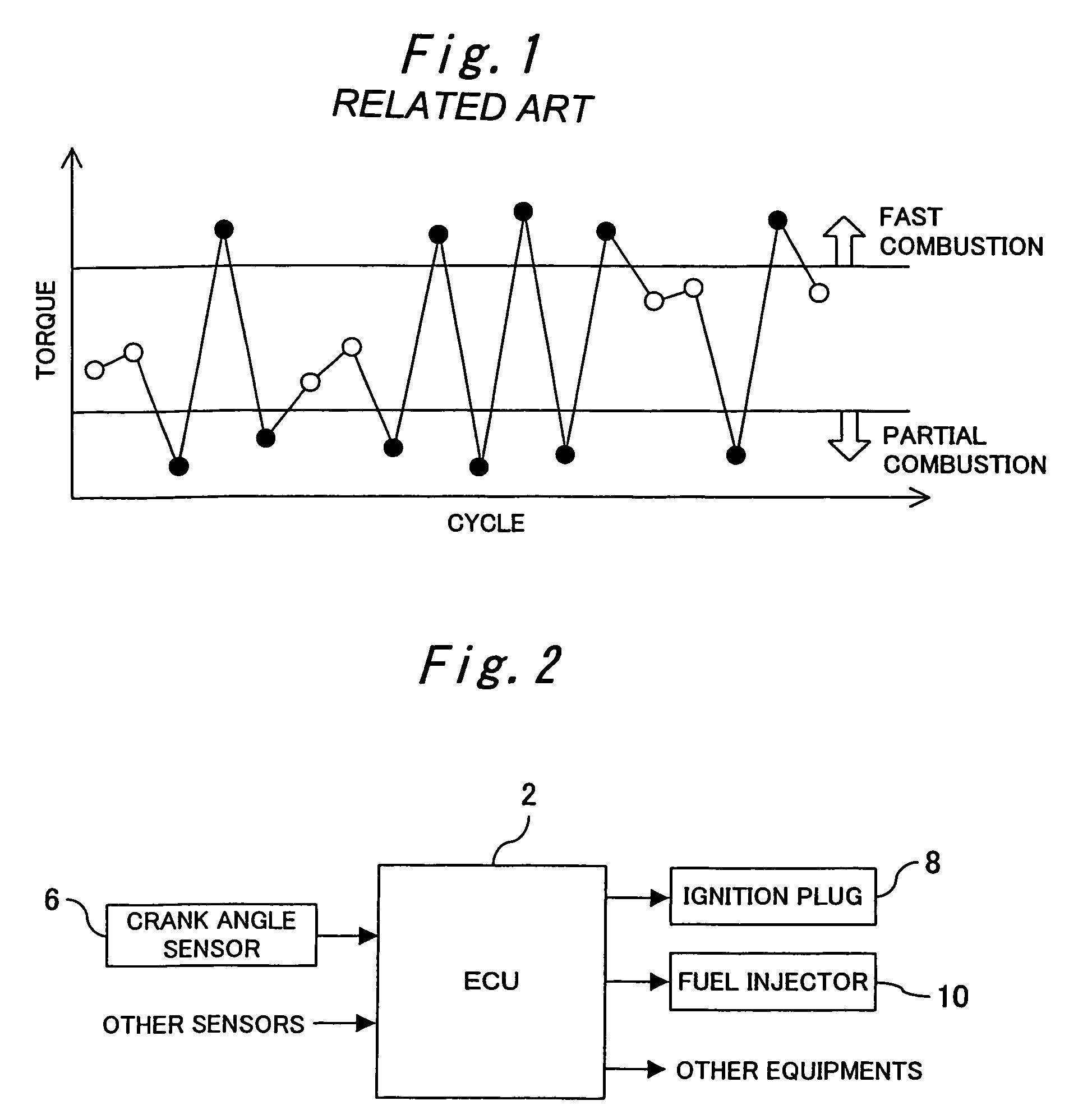

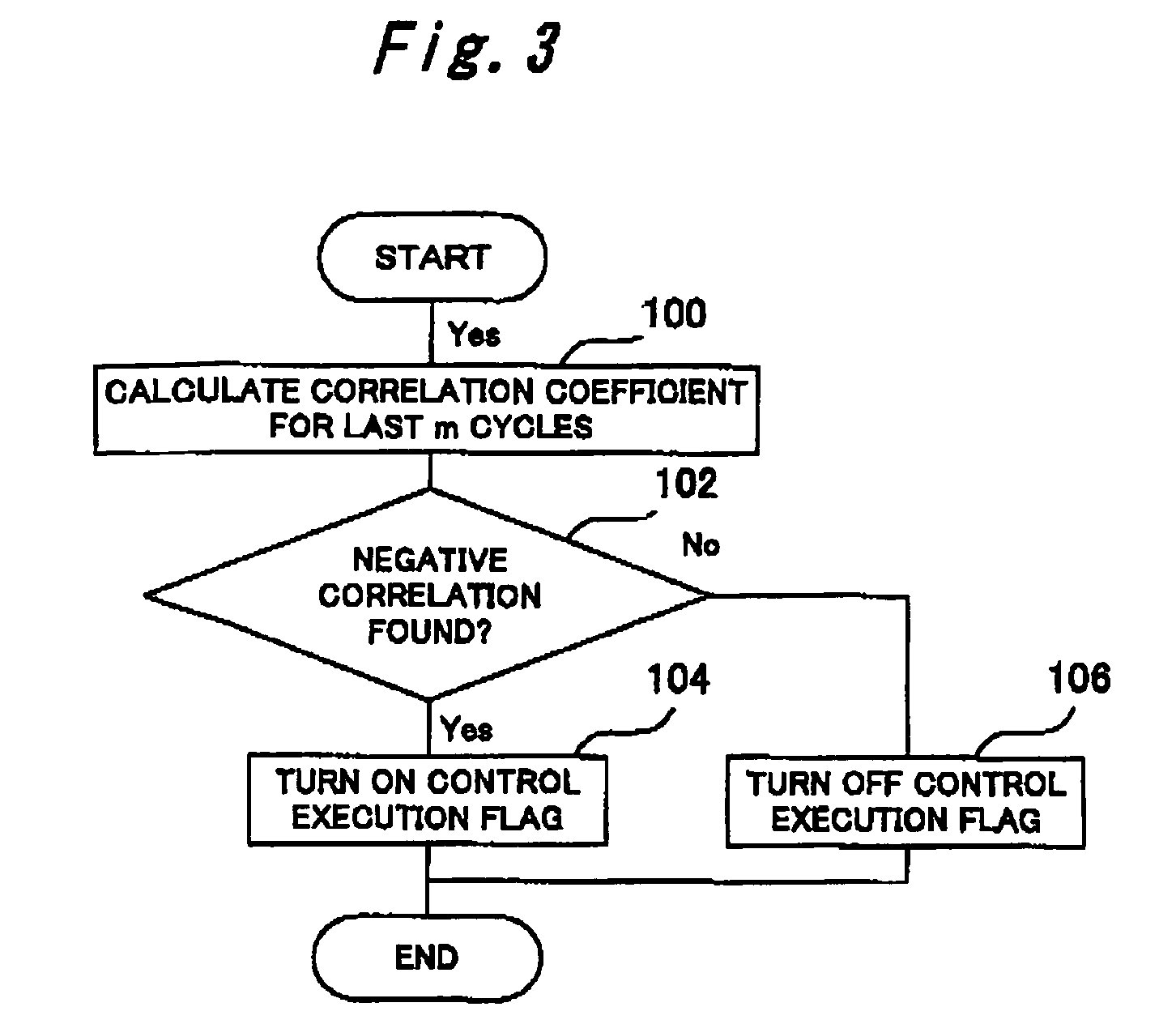

[0034]FIGS. 2 through 10 illustrates the first embodiment of an internal combustion engine controller according to the present invention. The internal combustion engine controller according to the present invention serves as an ECU (Electronic Control Unit). In accordance with output signals from a plurality of sensors, the ECU 2 exercises overall control of various equipments that concern the operating status of an internal combustion engine. As shown in FIG. 2, the input end of the ECU 2 according to the present embodiment is connected to a crank angle sensor 6. The output and of the ECU 2 is connected to an ignition plug 8 and a fuel injection valve 10. The crank angle sensor 6 is positioned near a crankshaft to output a signal to the ECU 2 at a predetermined crank angle position. The ECU 2 receives an output signal that is supplied from the crank angle sensor 6, an...

second embodiment

[0083]A second embodiment of the present invention will now be described with reference to FIG. 11.

[0084]The internal combustion engine controller according to the second embodiment is implemented by causing the ECU 2 according to the first embodiment to additionally perform a routine shown in FIG. 11.

[0085]A multicylinder engine, which has a plurality of cylinders, is generally used as an internal combustion engine for use with an automobile or other vehicle. In a multicylinder engine, all the employed cylinders usually have the same structure and are controlled in the same manner. All the cylinders are designed to generated the same torque. In reality and in many cases, however, there are stationary torque differences among the cylinders due, for instance, to differing fuel injection characteristics of injectors, nonuniform intake amounts because, for instance, of tappet clearance differences and intake interference between cylinders, combustion chamber cubic capacity differences ...

third embodiment

[0093]A third embodiment of the present invention will now be described with reference to FIG. 12.

[0094]The internal combustion engine controller according to the third embodiment is implemented by causing the ECU 2 according to the first embodiment to perform a routine shown in FIG. 12 in place of the routing shown in FIG. 4.

[0095]In the first embodiment, the indicated torque is estimated from an output signal supplied from the crank angle sensor 6 and compared against predetermined judgment value T1 and T2 to check whether the combustion status of the internal combustion engine is partial combustion or not or whether it is fast combustion or not. However, the reliability of a torque value cannot easily be assured due, for instance, to friction torque variation, aging, and crank angle sensor signal accuracy. Therefore, if the employed threshold values (judgment values T1 and T2) are the magnitude of torque values as mentioned above erroneous judgments may be formed depending on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com