Polymeric roof rail

a polymer and composite technology, applied in the direction of roofs, mechanical equipment, transportation and packaging, etc., can solve the problems of heavy and/or expensive roof rails, and achieve the effect of improving strength to weight functionality, simple manufacturing of composite roof rails, and facilitating the contouring of exterior shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]The following description of the preferred embodiments is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses.

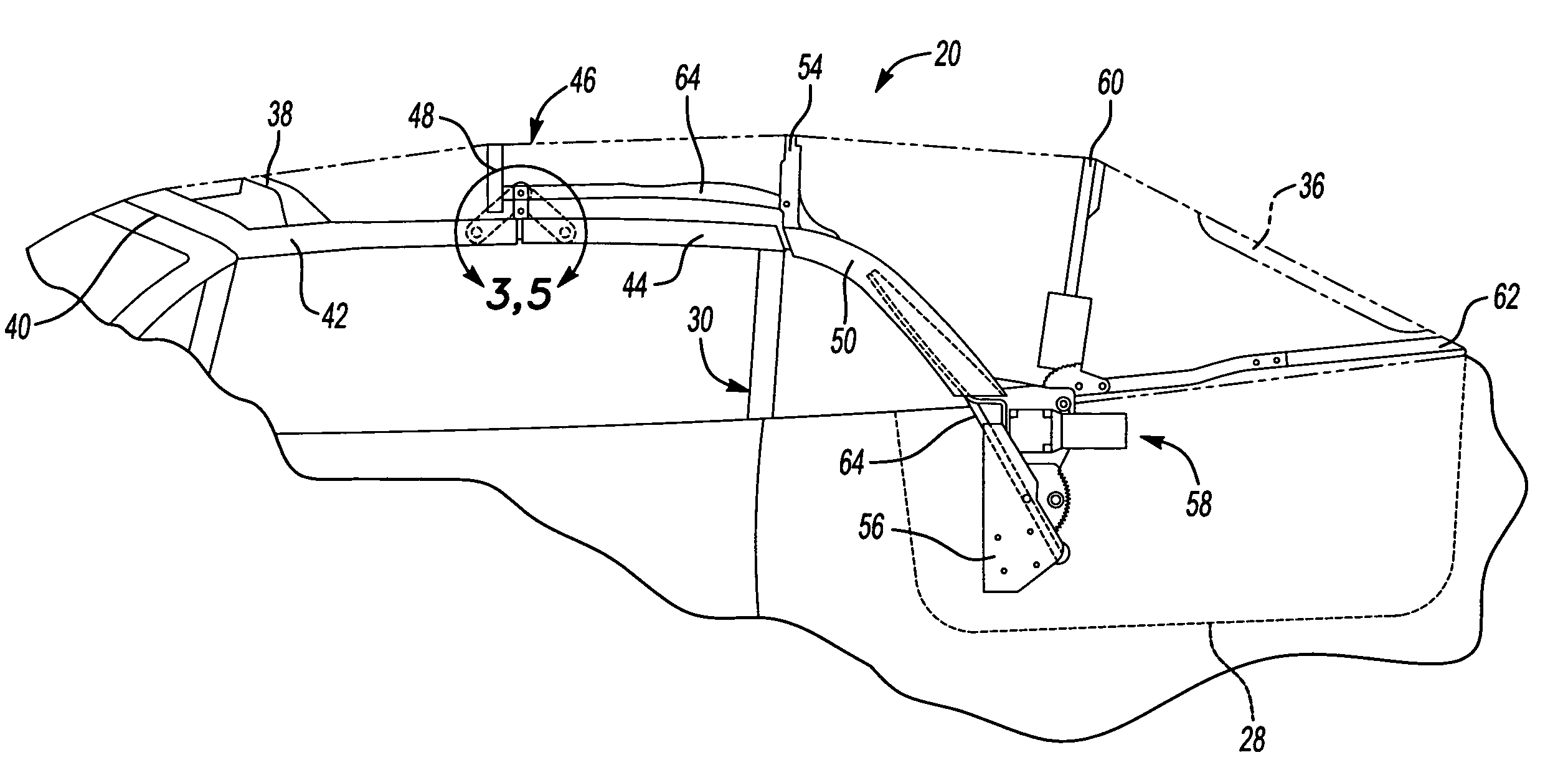

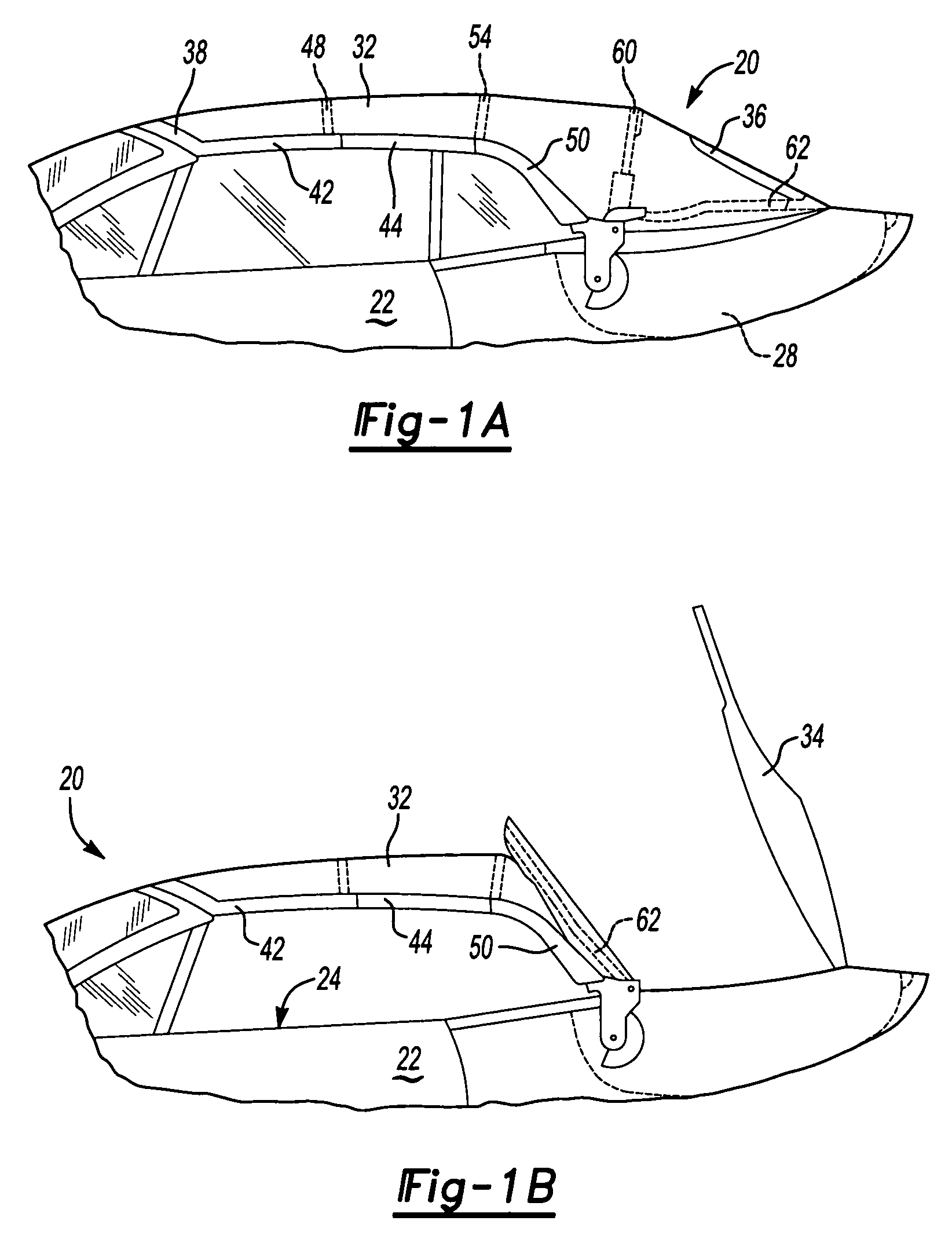

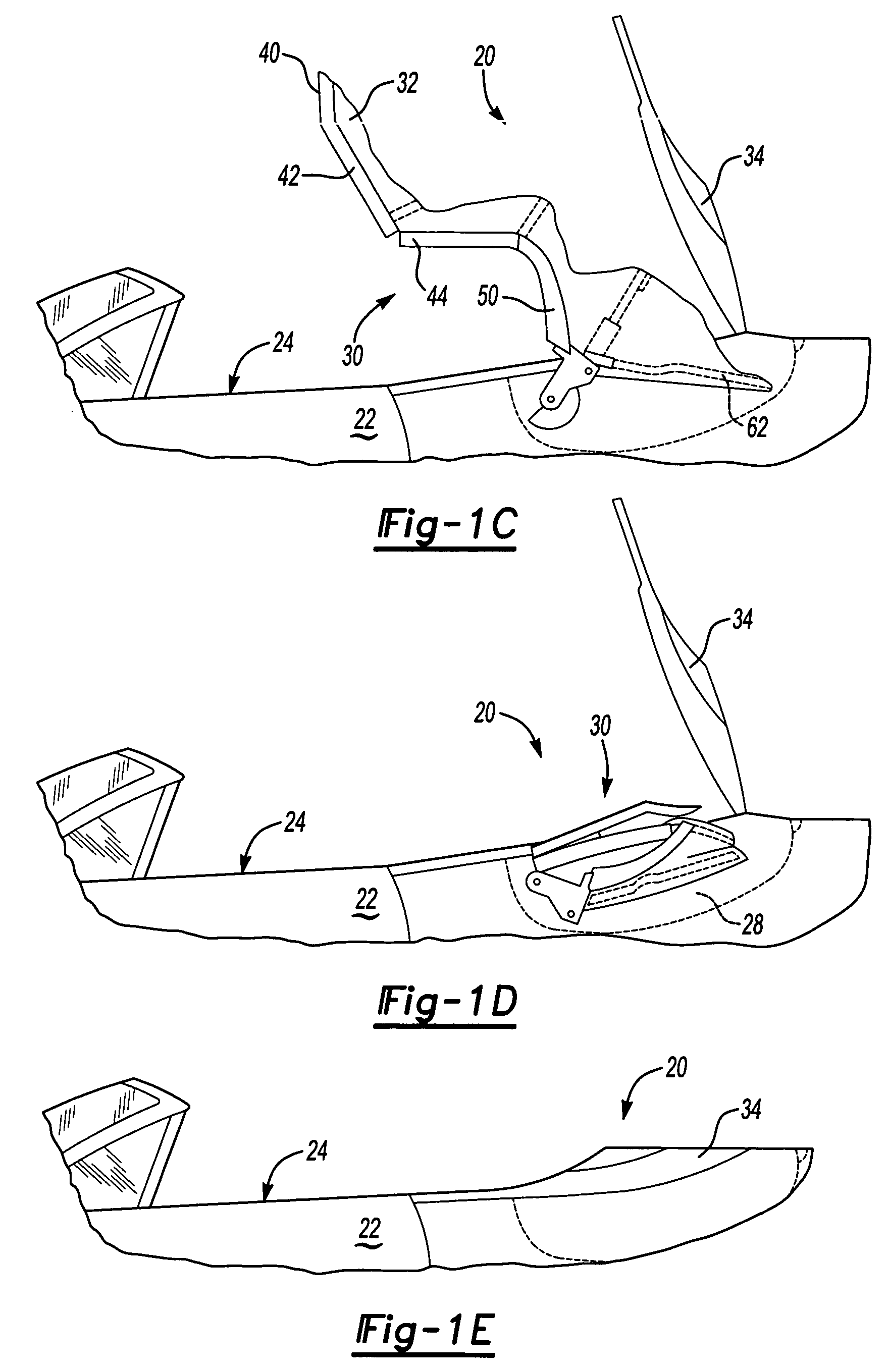

[0026]Referring to FIGS. 1A–E, a convertible roof system 20 according to the principles of the present invention is shown installed on an automotive vehicle 22 having a passenger compartment 24 and a stowage compartment 28. Convertible roof system 20 is the type utilizing a folding or top stack mechanism 30 that partially supports a roof cover 32 and is operable between a fully raised or extended position, as shown in FIG. 1A, through intermediate positions such as those shown in FIGS. 1B–D, and a fully stowed or retracted position within stowage compartment 28 beneath a tonneau cover 34, as shown in FIG. 1E.

[0027]Roof cover 32 includes a window or backlite 36 and is made from a pliable material, such as vinyl, canvas or a polyester fabric. If desired, roof cover 32 can also include a hard or rigid portion that optional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com