Readily degradable resin composition and biodegradable container using the same

a biodegradable and resin composition technology, applied in the direction of rigid containers, synthetic resin layered products, packaging, etc., can solve the problems of inability to fully degrade the whole container in a considerable time, the biodegradable container has readily degradable portions and hardly degradable portions, and achieves excellent biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

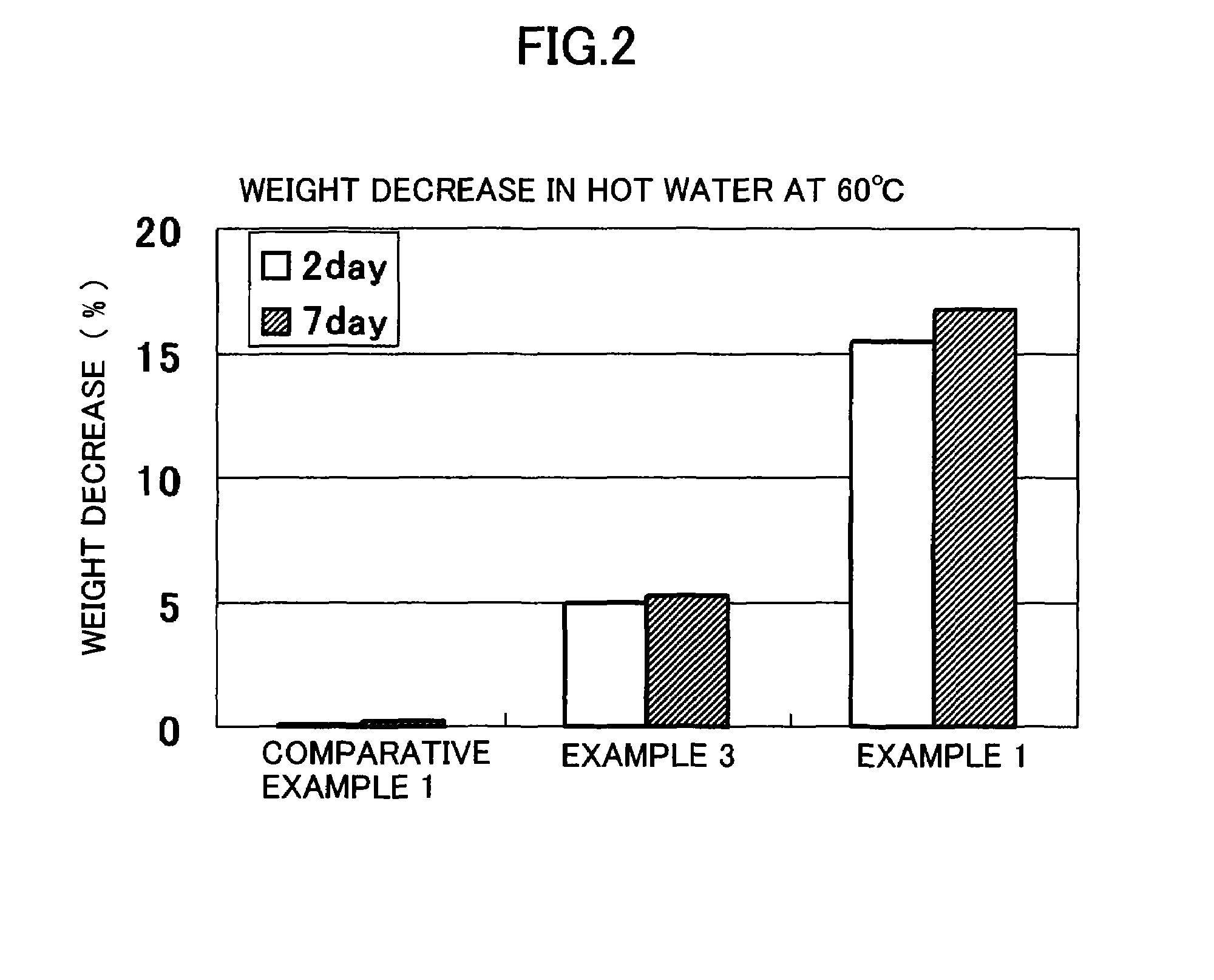

example 1

Formation of Cast Film of Blended Polymer

[0040]0.80 g of polylactic acid (LACEA H-100 manufactured by Mitsui Chemicals, Inc.) and 0.20 g of polyethylene oxalate were dissolved in 10 to 12 ml of an HFIP solvent (hexafluoroisopropanol manufactured by Central Glass Co., Ltd.) to achieve a content of polyethylene oxalate in polylactic acid of 20% by weight, and then the mixture was cast on a Petri dish. After the cast, overnight drying was performed in a vacuum dryer kept at 40° C. The film thickness after drying was 40 μm.

(Enzymatic Degradation Test)

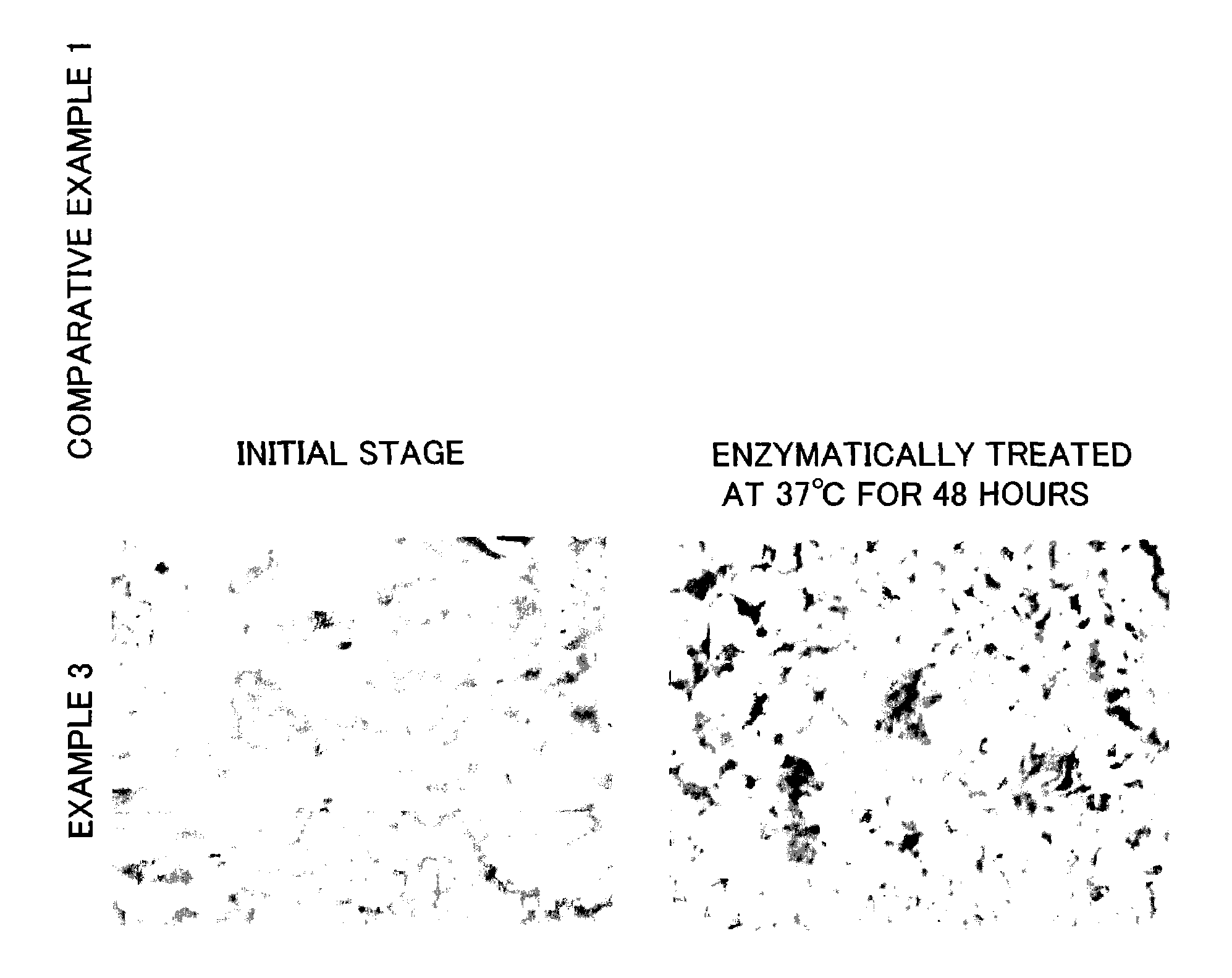

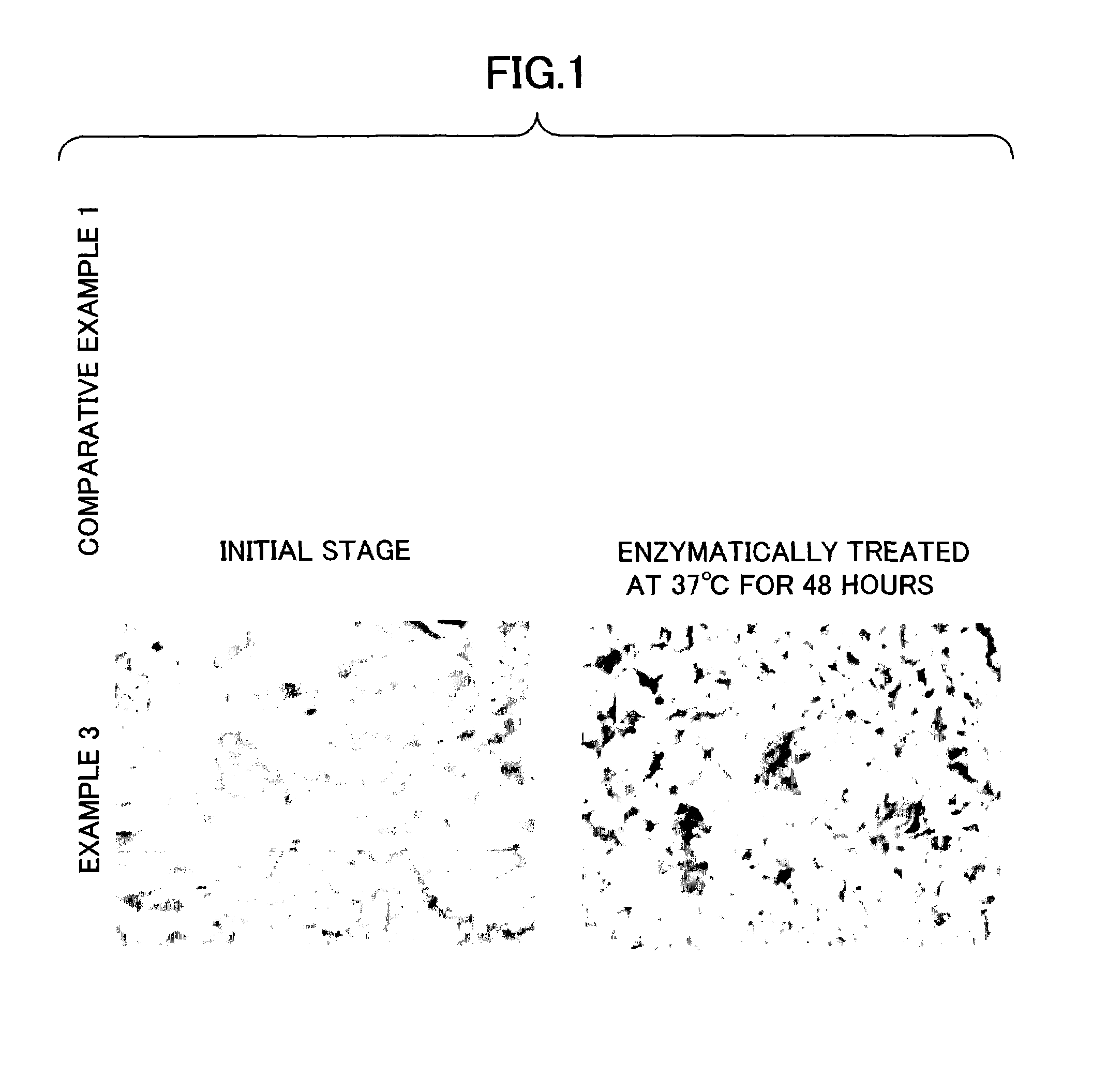

[0041]An enzymatic degradation solution was prepared by adding 12 μl of the enzyme solution into 10 ml of the 0.01 M Tris-HCl buffer (pH 8.0). Into the enzymatic degradation solution, the cast film cut into 1 cm×2 cm was immersed, and shaken at 37° C. and at 50 rpm. 16 hours, 48 hours, 120 hours, and 168 hours after the start of the degradation, the degradation state of the film was visually observed and the enzyme solution was exchanged. T...

example 2

[0042]Example 2 was conducted in the same manner as that in Example 1 except that the temperature in the enzymatic degradation test was changed to 60° C.

example 3

[0043]Example 3 was conducted in the same manner as that in Example 1 except that the content of polyethylene oxalate was changed to 5% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com