Process for the production of methanol including one or more membrane separation steps

a technology of methanol and membrane separation, which is applied in the direction of separation process, oxygen-containing compound preparation, oxygen-containing compound purification/separation, etc., can solve the problems of unnecessary costs, and achieve the effect of preventing its release to the environment and reducing the compression requirements of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Conventional Methanol Production Process (not in Accordance with the Invention)

[0084]The computer calculations in the following Examples were performed using a modeling program, ChemCad 5.6 (ChemStations, Inc., Houston, Tex.) containing code developed by assignee's engineering group for applications specific to assignee's processes.

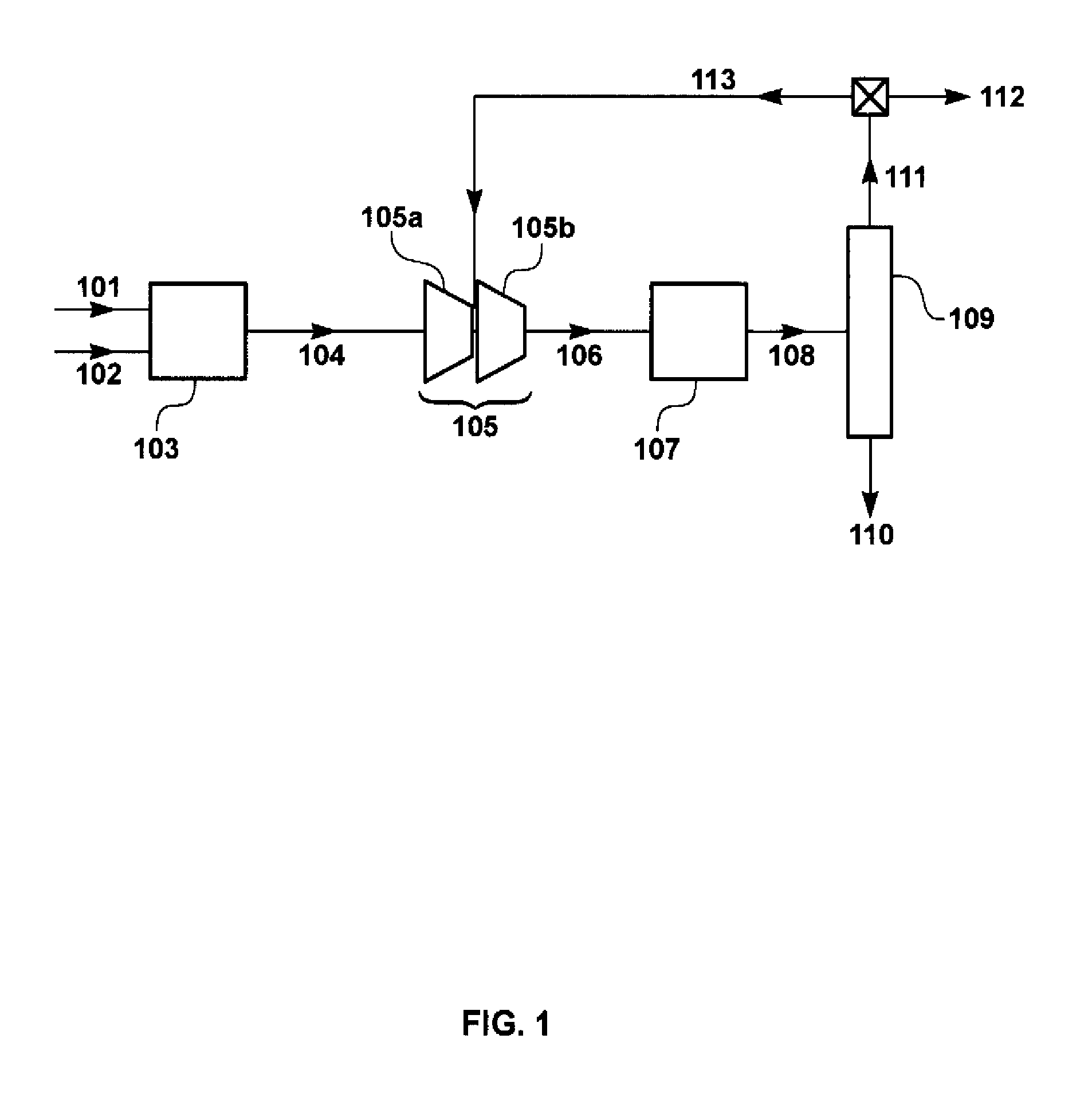

[0085]The calculation for this Example was performed using the flow scheme shown in FIG. 1 and described in the Background of the Invention, above. This flow scheme does not include a membrane separation step upstream of the methanol synthesis process (not in accordance with the invention). Syngas flow was assumed to be 106 metric tons per hour (Mt / h).

[0086]The flow rates and chemical compositions of the streams in the methanol synthesis loop were calculated. The results of this calculation are shown in Table 1.

[0087]

TABLE 1ReactorReactorOverheadRecycleSyngasFeed GasOutputCondensateStreamPurge GasGasParameter / Stream104106108110111112113Total Flow (Mt / h)10...

example 2

Methanol Production Process in Accordance with the Invention

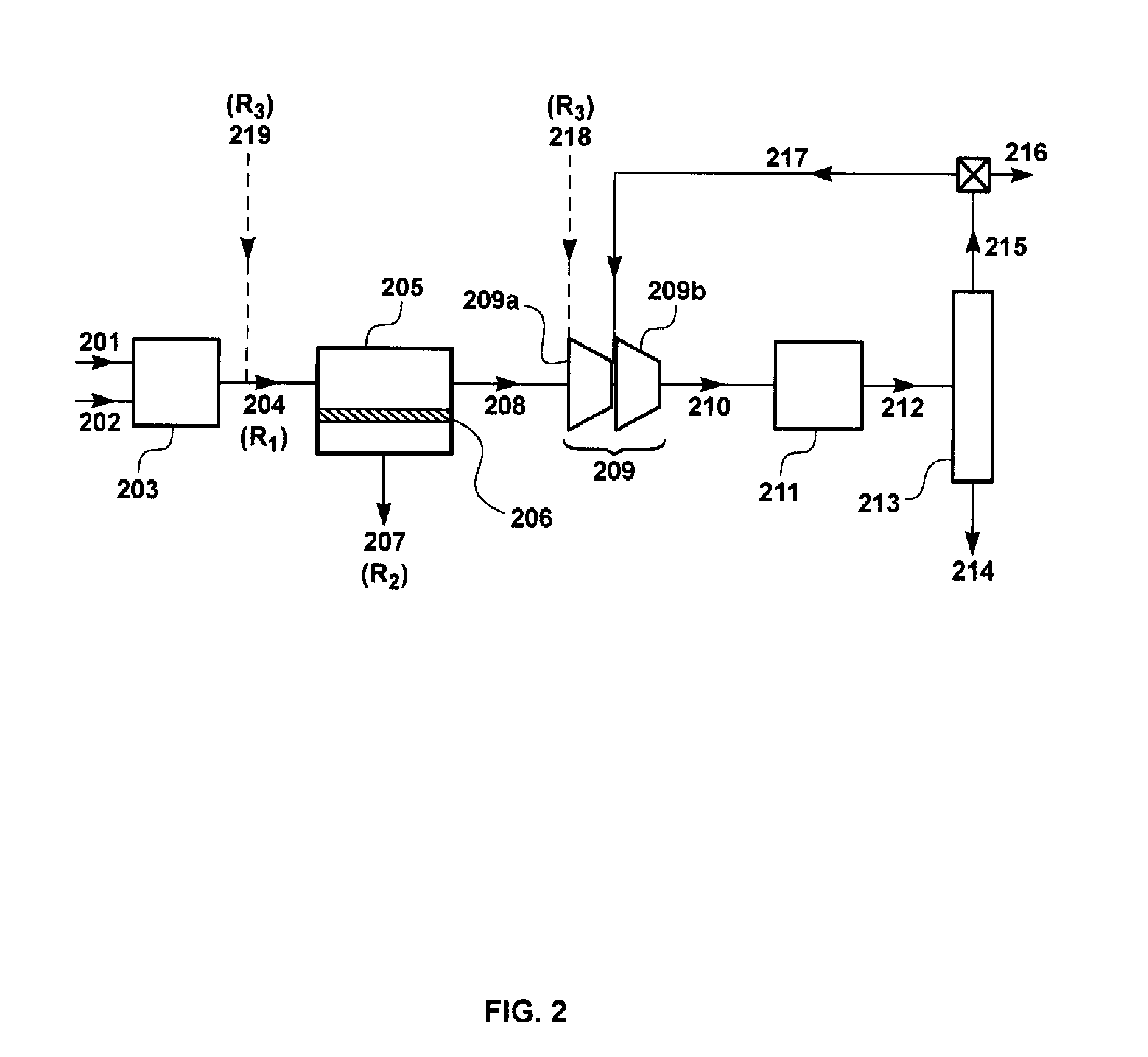

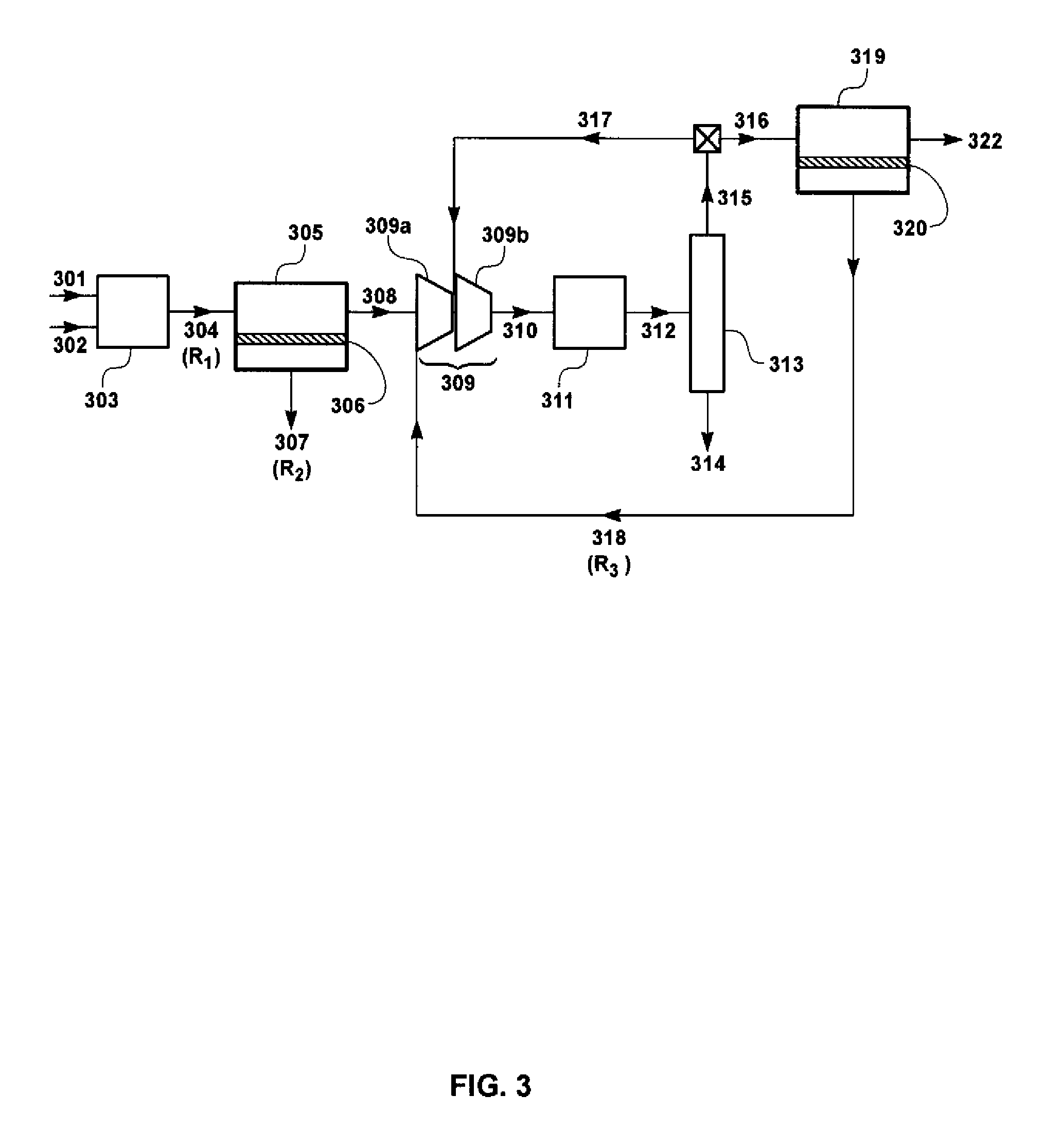

[0089]The calculation for this Example was performed using the flow scheme shown in FIG. 2 and described in the Detailed Description, above. This flow scheme includes a membrane separation step upstream of the methanol synthesis loop.

[0090]The membranes, 206, in membrane separation unit, 205, were assumed to have the properties shown in Table 2, at a membrane operating temperature within the range of about 50° C. and about 150° C.

[0091]

TABLE 2GasPermeance (gpu)*H2 / Gas Selectivity**Hydrogen300—Carbon monoxide>100Carbon dioxide2015Methane>100Nitrogen>100Water5000.6*Gas permeation unit; 1 gpu = 1 × 10−6 cm3(STP) / cm2 · s · cmHg**Estimated, not measured

[0092]As with Example 1, syngas flow for this calculation was assumed to be 106 Mt / h. The flow rates and chemical compositions of the streams in the methanol synthesis loop were calculated. The results of this calculation are shown in Table 3.

[0093]

TABLE 3ReactorMembraneTreatedFee...

example 3

Methanol Production Loss from Co-Permeation of Carbon Dioxide

[0096]Many hydrogen-permeable membranes show good selectivity for hydrogen over carbon monoxide. However, good selectivity for hydrogen over carbon dioxide is much harder to realize. Because of this, a series of calculations of the type described in FIG. 2 was performed, varying the hydrogen / carbon dioxide selectivity from 3 to 15. The results of the calculations were used to create the curves shown in FIG. 4, which is a plot 400 showing methanol production loss (due to co-permeation of carbon oxides) 401 as a function of membrane hydrogen / carbon dioxide selectivity 402. Curve 403 represents a permeate stream pressure of 4 bar (60 psia); curve 404 represents a permeate stream pressure of 2 bar (30 psia). Feed stream pressure in both cases was 240 psia.

[0097]As can be seen from the figure, at a given membrane selectivity, methanol production loss from co-permeation of carbon oxides is slightly higher at a permeate pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com