Chassis for a motor vehicle having an electrical axle

a technology for motor vehicles and axles, applied in the direction of electric propulsion mounting, electric devices, gearing, etc., can solve the problems of inability to permit any relevant change in length, the design of chassis or axles disadvantageously relates to rigid portal axles, etc., to increase the maximum torque, reduce consumption, and increase the power of the vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

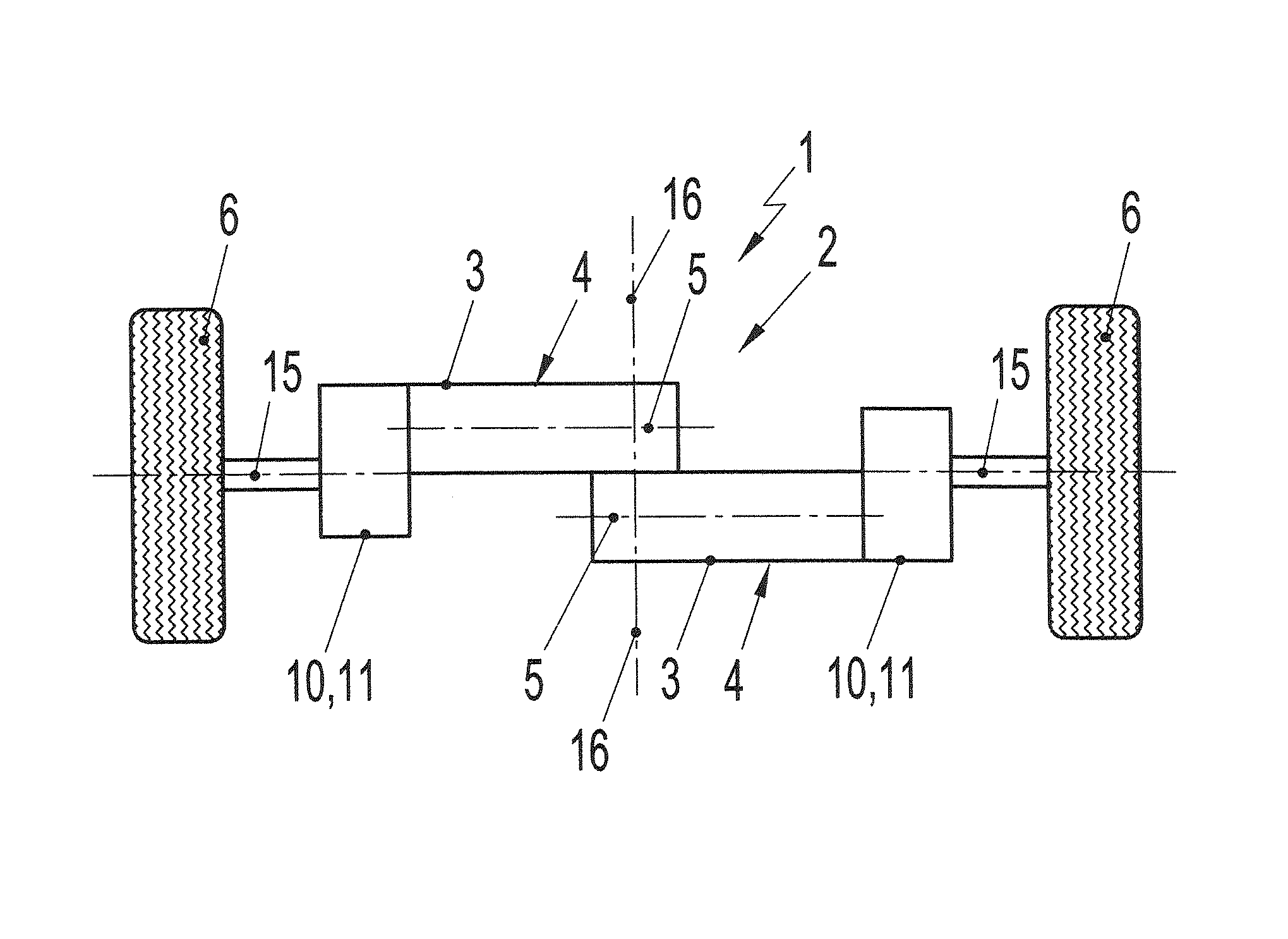

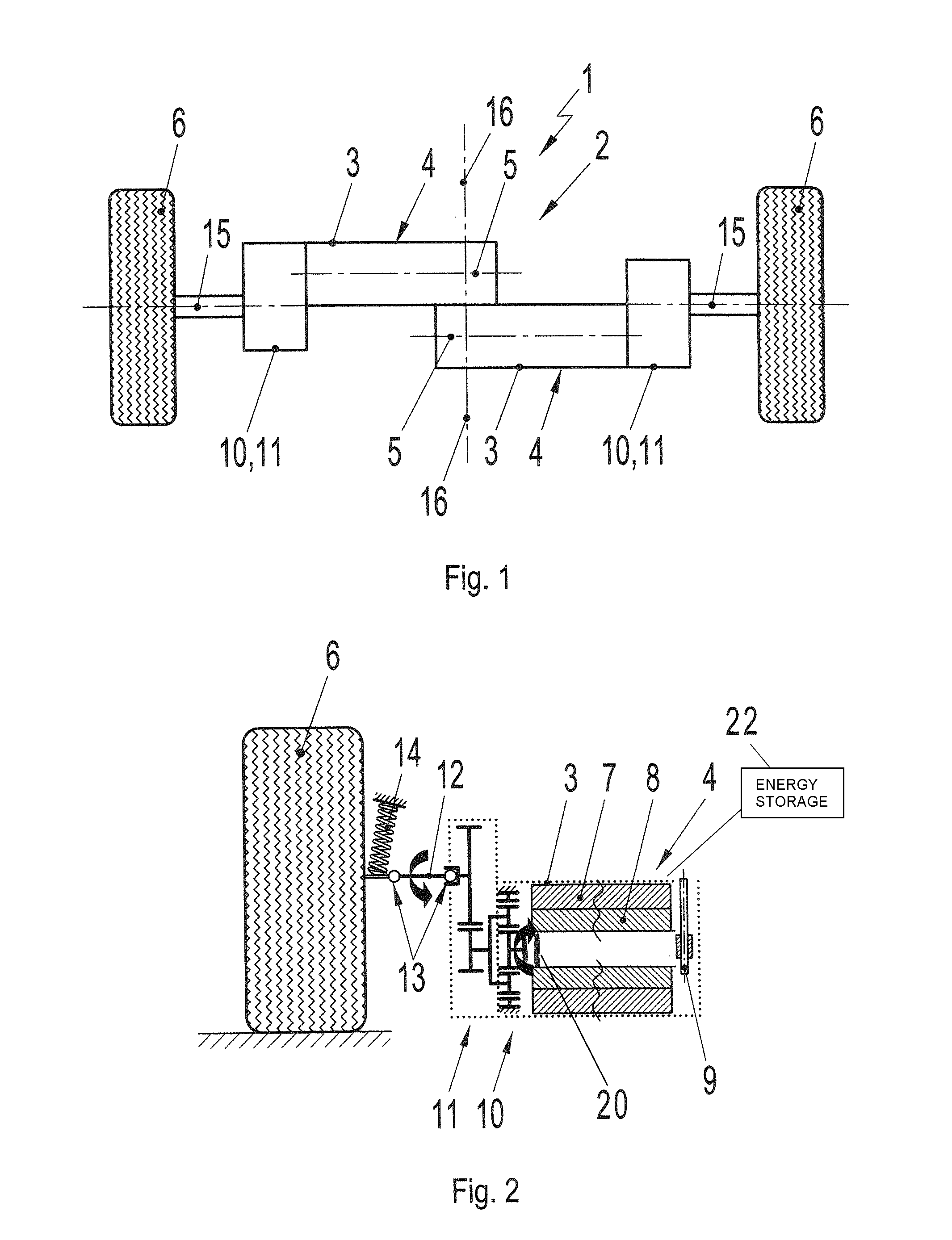

[0031]The motor vehicle equipped with the chassis of the invention preferably is a car intended to be used in racing. The individually suspended wheels of the car that are associated with the rear axle are driven by an internal combustion engine. The wheels associated with the front axle also are individually suspended and can be driven by electric motor to apply an additional drive torque by means of the front wheels. The following description relates to the design of the motor vehicle in the region of the front axle and the chassis of the invention in this respect. This chassis 1 has an electrical axle 2 that is designed as a portal axle with two portal axle sections in the form of tubes that represent the housings 3 for accommodating two electrical machines 4. The housings 3 and the electrical machines 4 are arranged parallel and next to one another in relation to their rotation axes 5, with the spacing between the rotation axes 5, taking into account the outside diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com