Male external catheter and method of making same

a catheter and catheter tube technology, applied in the field of male external catheters and methods of making same, can solve the problems of inability to collect and retain small amounts of urine within the annular channels or grooves, and the disadvantage of collecting and retaining urine within the annular channels or grooves, and achieves smooth tapering, eliminating or reducing the possibility, and enhancing the effect of flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

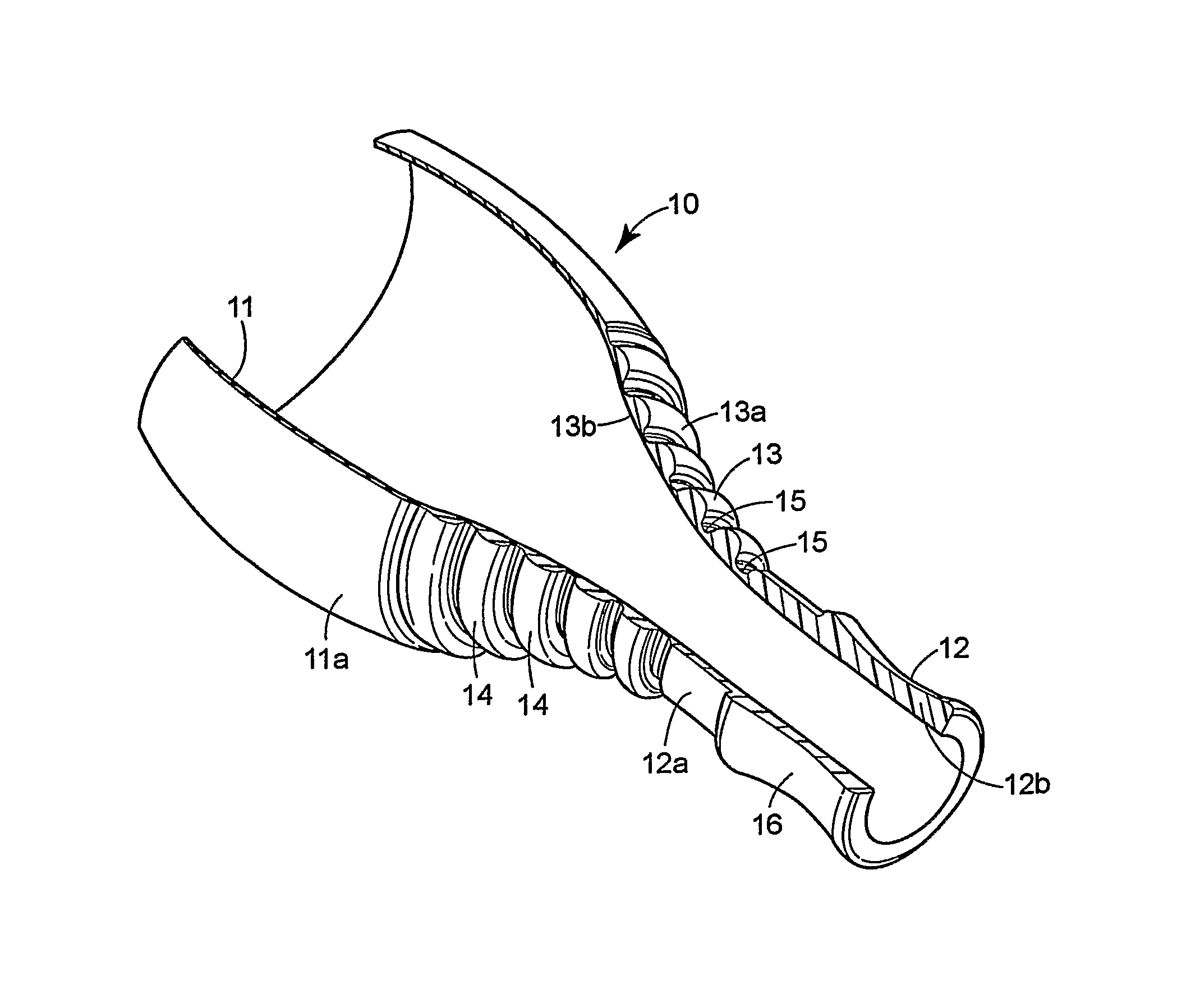

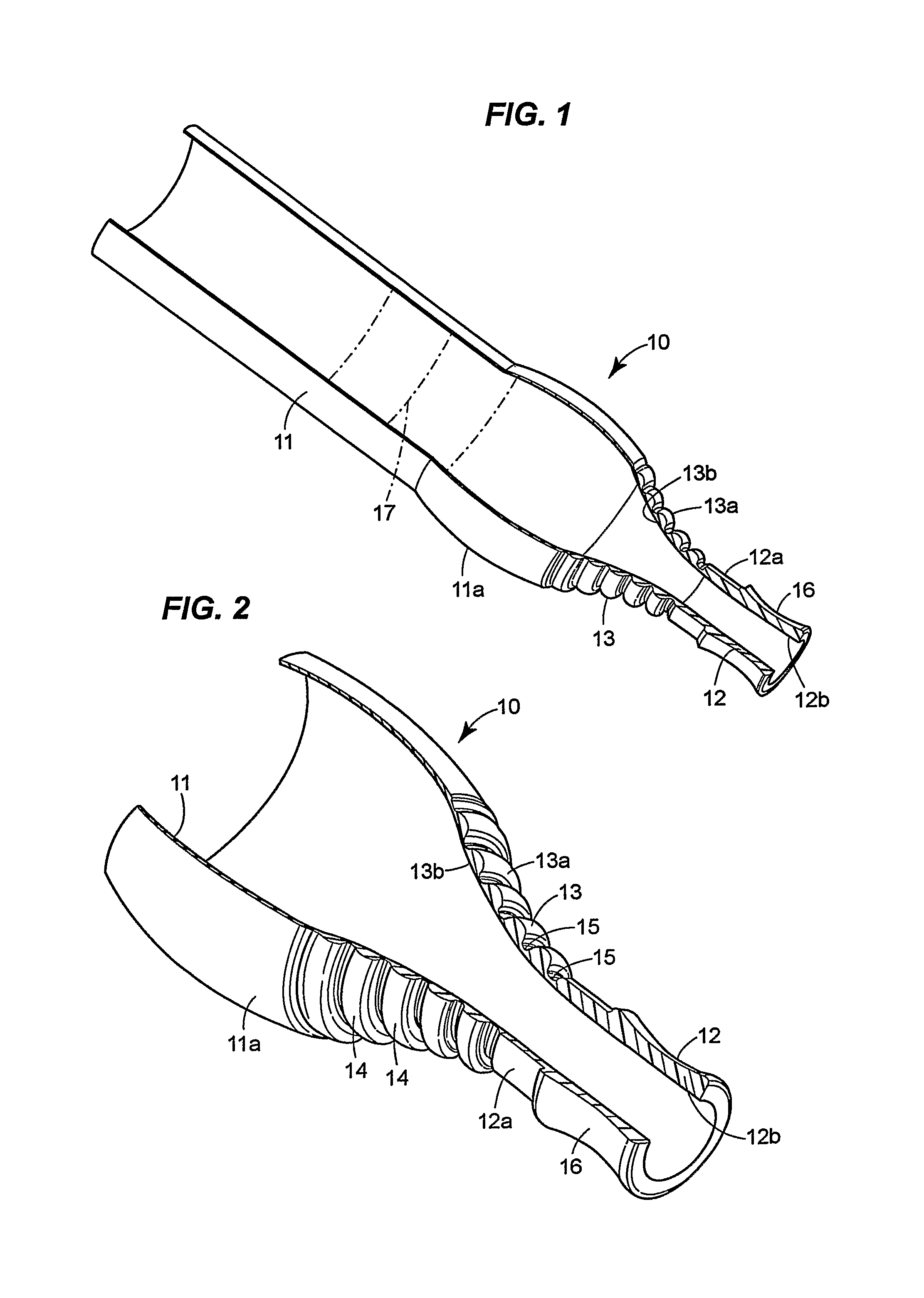

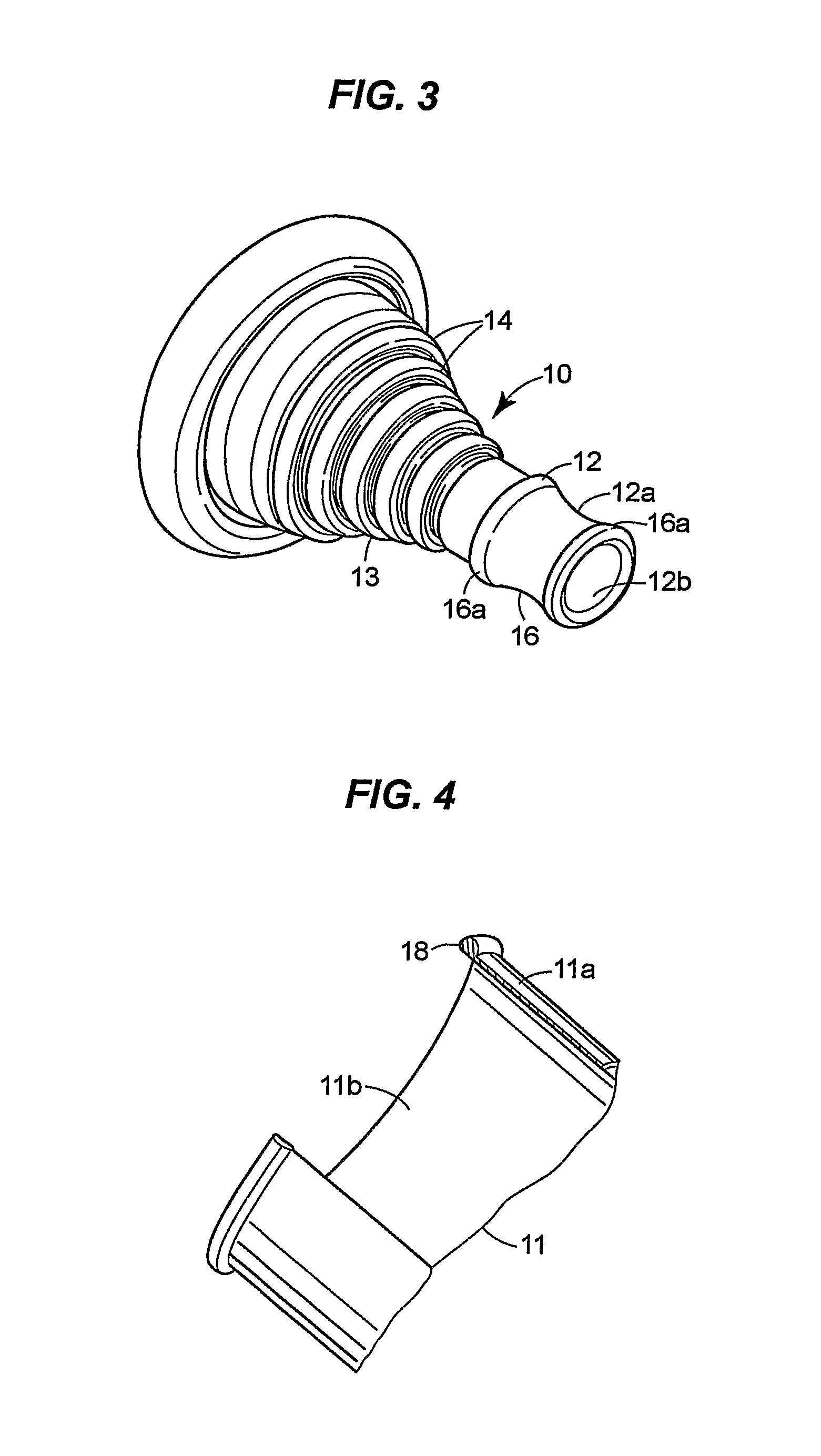

[0019]Referring to FIGS. 1 and 2 of the drawings, the numeral (10) generally designates a male external catheter injection molded in whole or in part from one or more injection-moldable plastic materials and having an elongated cylindrical body section (11) a drain tube section (12), and a tapered funnel or neck section (13) interposed between and joining the body and drain tube sections. If desired, the body section may have a bulbous portion (11a) at its distal end, such portion serving both as a glans-receiving chamber for enhancing wearer comfort and as an expandable surge chamber for temporarily accommodating surges of fluid that may occur at the commencement of urination.

[0020]In the illustration given, the sections of the external catheter are integrally formed, but as explained hereinafter, certain sections such as the drainage tube section may be injection molded as a separate component and joined to the remainder of the catheter through overmolding or multi-shot injection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thermoplastic | aaaaa | aaaaa |

| stretchable | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com