Solid defoaming agent

a degasification agent and solid-state technology, applied in the direction of liquid degasification, separation process, other chemical processes, etc., can solve the problems of increased operation costs of wastewater treatment plants, difficult to control the foam elimination effect, and easy blockage of the pump and pipe of related equipmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]Defoaming / Antifoaming agents are a repeat chemical engineering product with a wide variety of applications used in textile, printing and dyeing, pulp and paper, food, chemical engineering, petroleum, leather, cleaning, wastewater treatment and related fields. Antifoaming agents not only have fast foam elimination and long-duration foam suppression capabilities, but also other numerous advantages, such as wide applications, low cost, easy production, small investment in equipments, short production cycle, no environmental pollution and considerable profit.

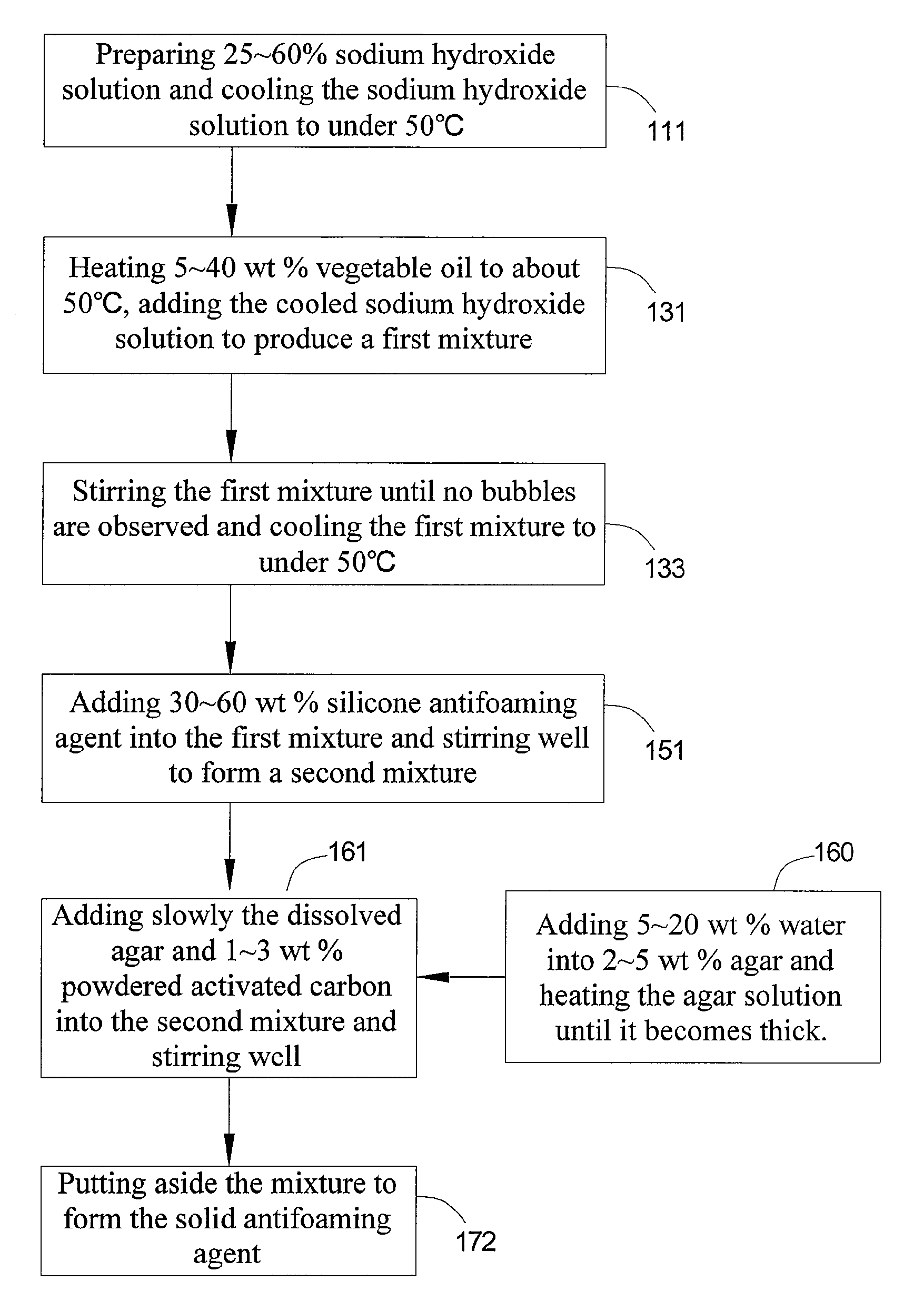

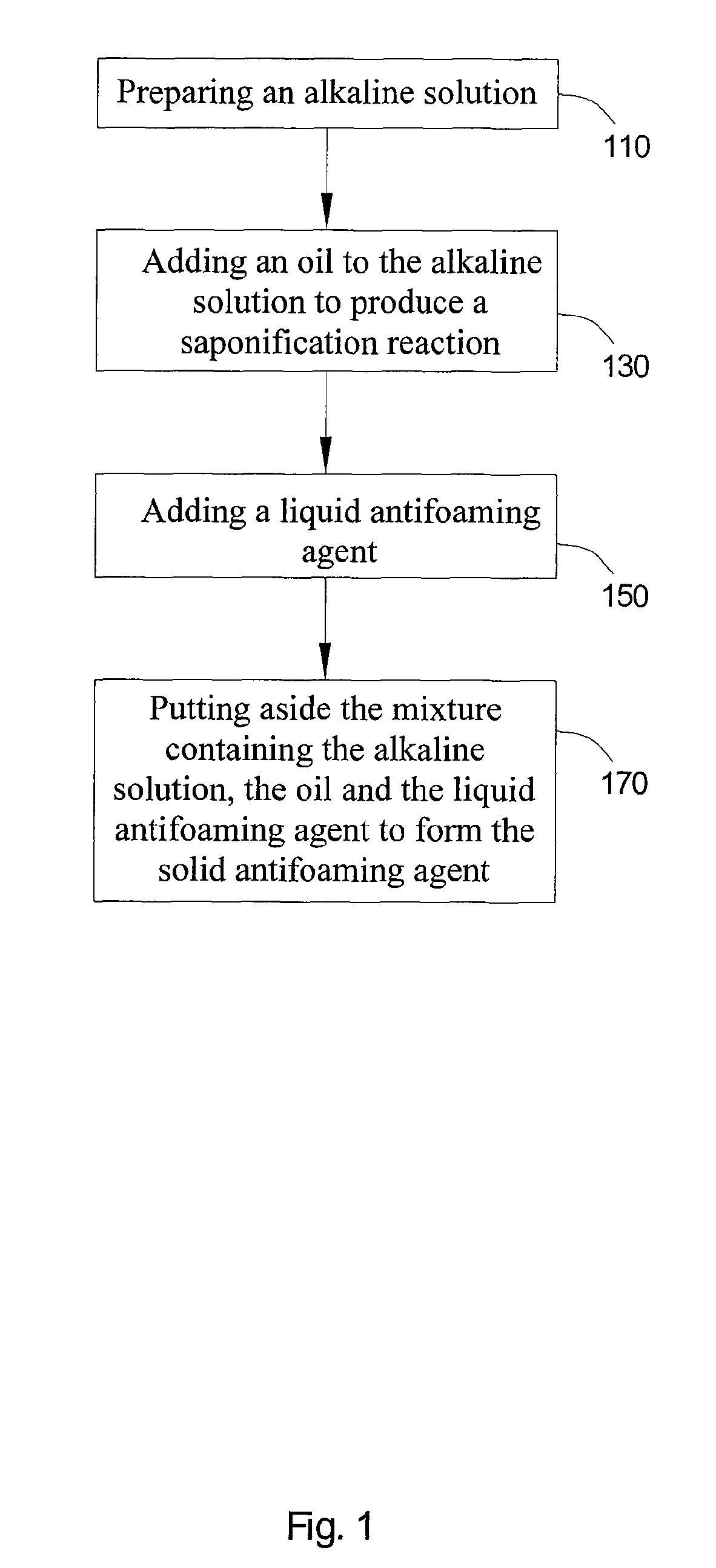

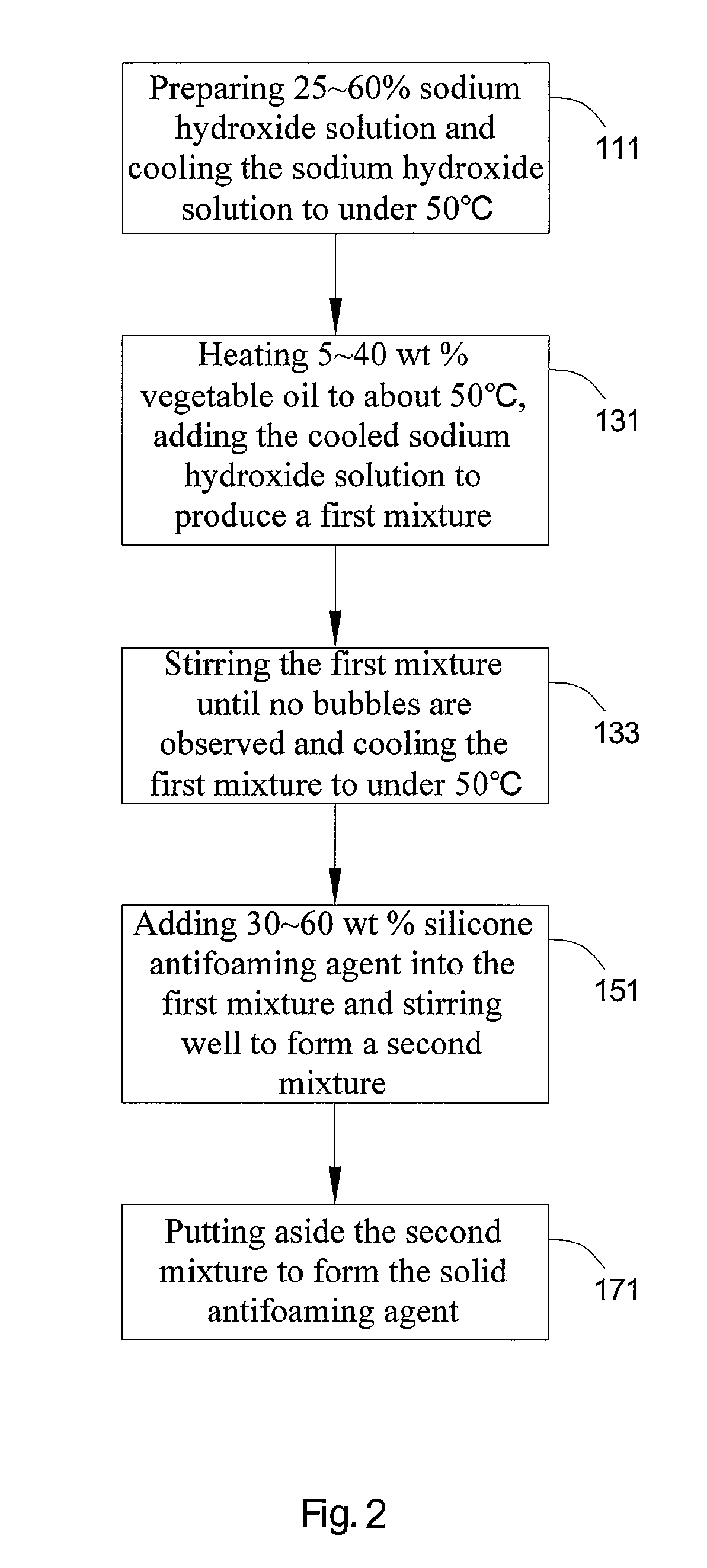

[0020]The present invention provides a solid antifoaming agent and manufacturing method thereof. As shown in FIG. 1, the manufacturing method of the solid antifoaming agent in accordance with the present invention comprises at least four main steps: step 110 is preparing an alkaline solution; step 130 is adding an oil to the alkaline solution to produce a saponification reaction; step 150 is adding a liquid antifoaming agent; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com