Apparatus for activity controlled waste incinerator afterburner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

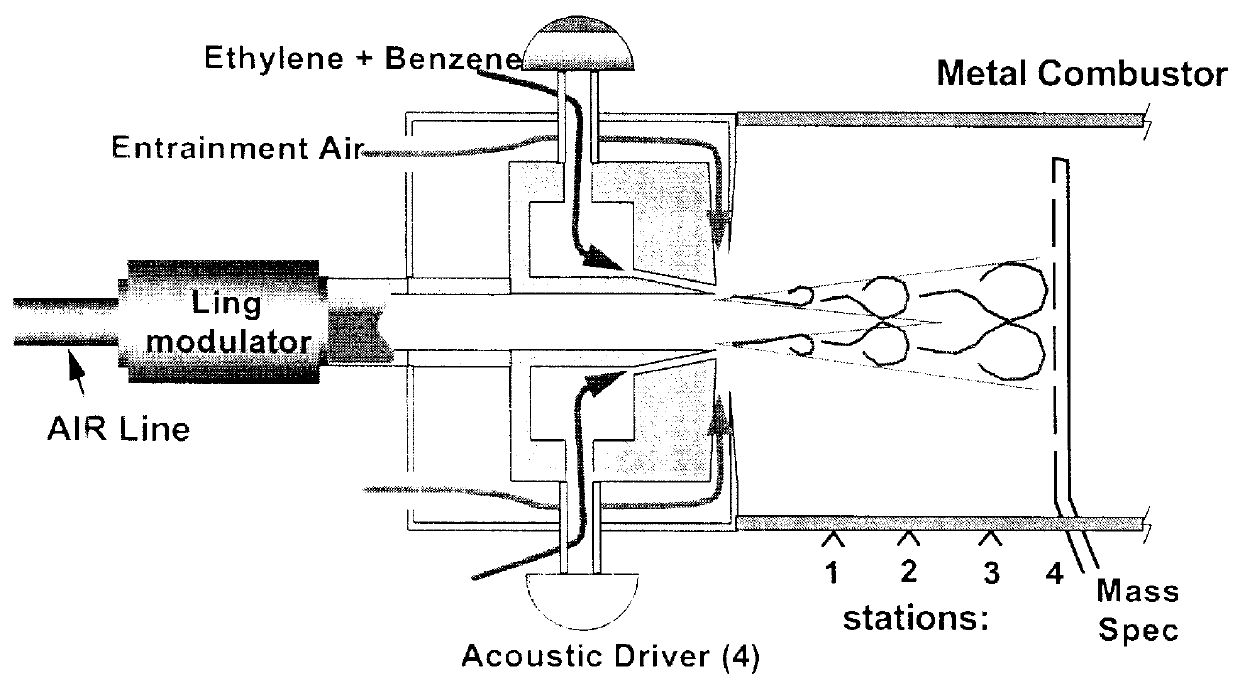

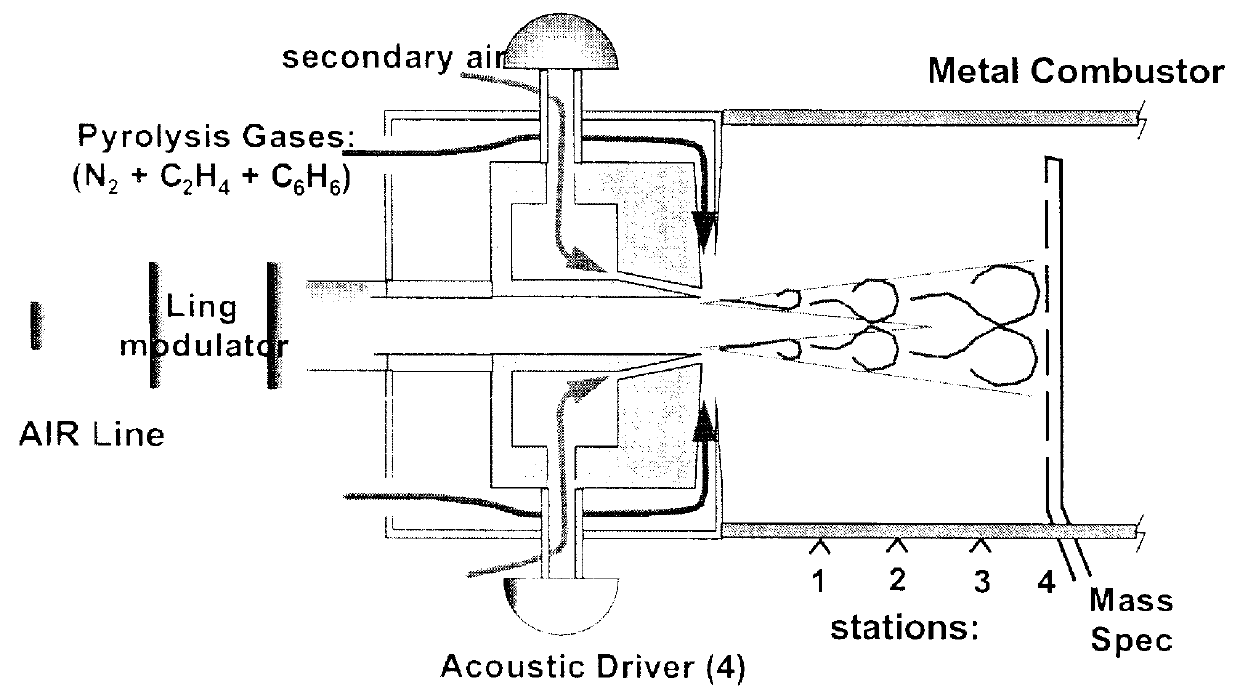

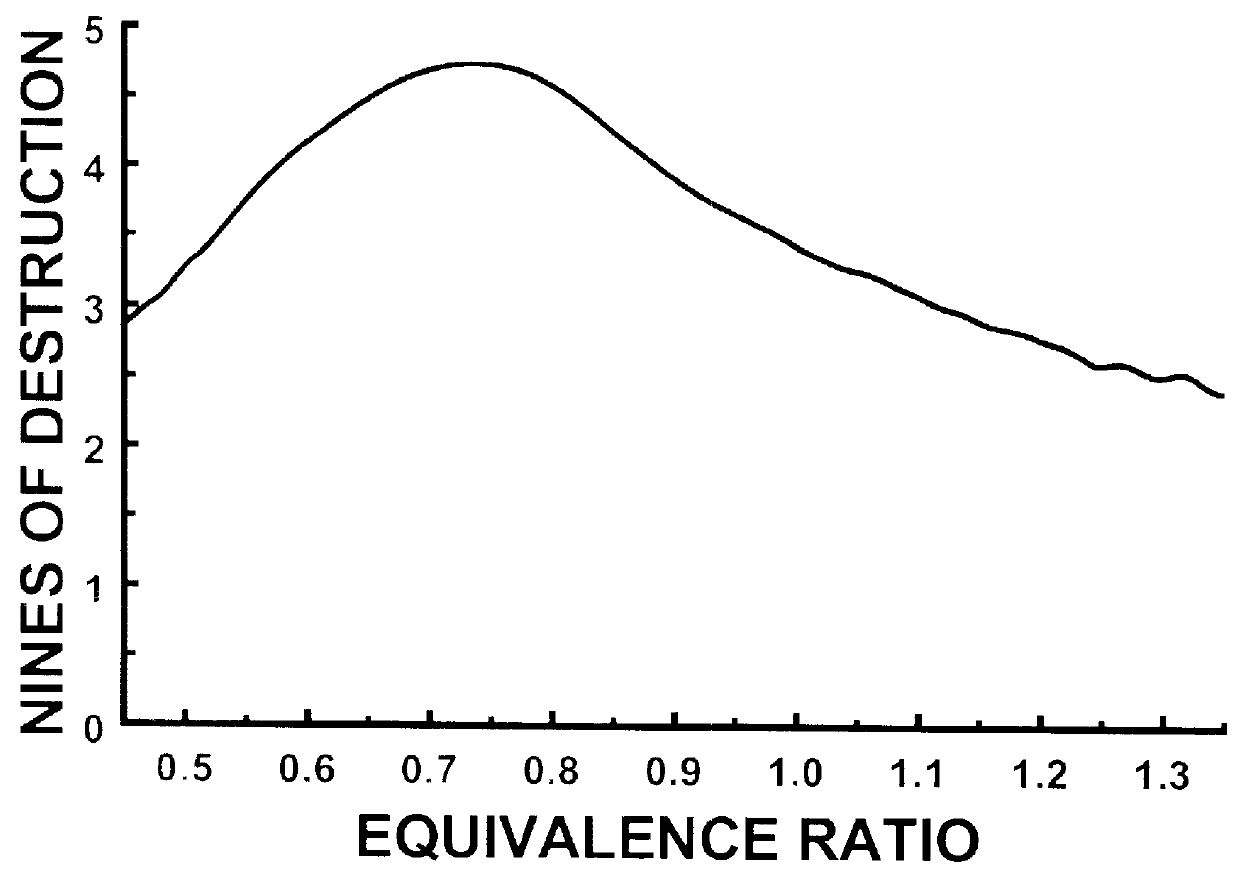

As discussed earlier, this invention comprises an improved technique for the modulation of waste in an actively controlled compact waste incinerator. This invention utilizes acoustic driving to affect indirect modulation of waste flow velocities. Waste surrogate gases are modulated indirectly by periodic entrainment created by the roll-up of the main air vortex, as well as indirect acoustic excitation of secondary air injection (FIG. 2). In both cases, the phase angle is controlled such that the combustibles are introduced into the air vortex at the proper time during the vortex formation resulting in good mixing, a controlled yet lifted partially premixed flame, high waste destruction efficiency, and low pollutant emissions. As discussed, the advantage in this new configuration is that the acoustic drivers used to phase inject the waste into the vortex for proper combustion are not in direct contact with the hot waste.

Active control of fluid dynamics has been used to enhance mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com