Dental implant system

a technology of implant system and implant, which is applied in the field of dental implant system, can solve the problems of bone erosion and trauma, relative large trauma area, and risk of post-operative infection, and achieve the effect of reducing tissue trauma and minimal trauma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

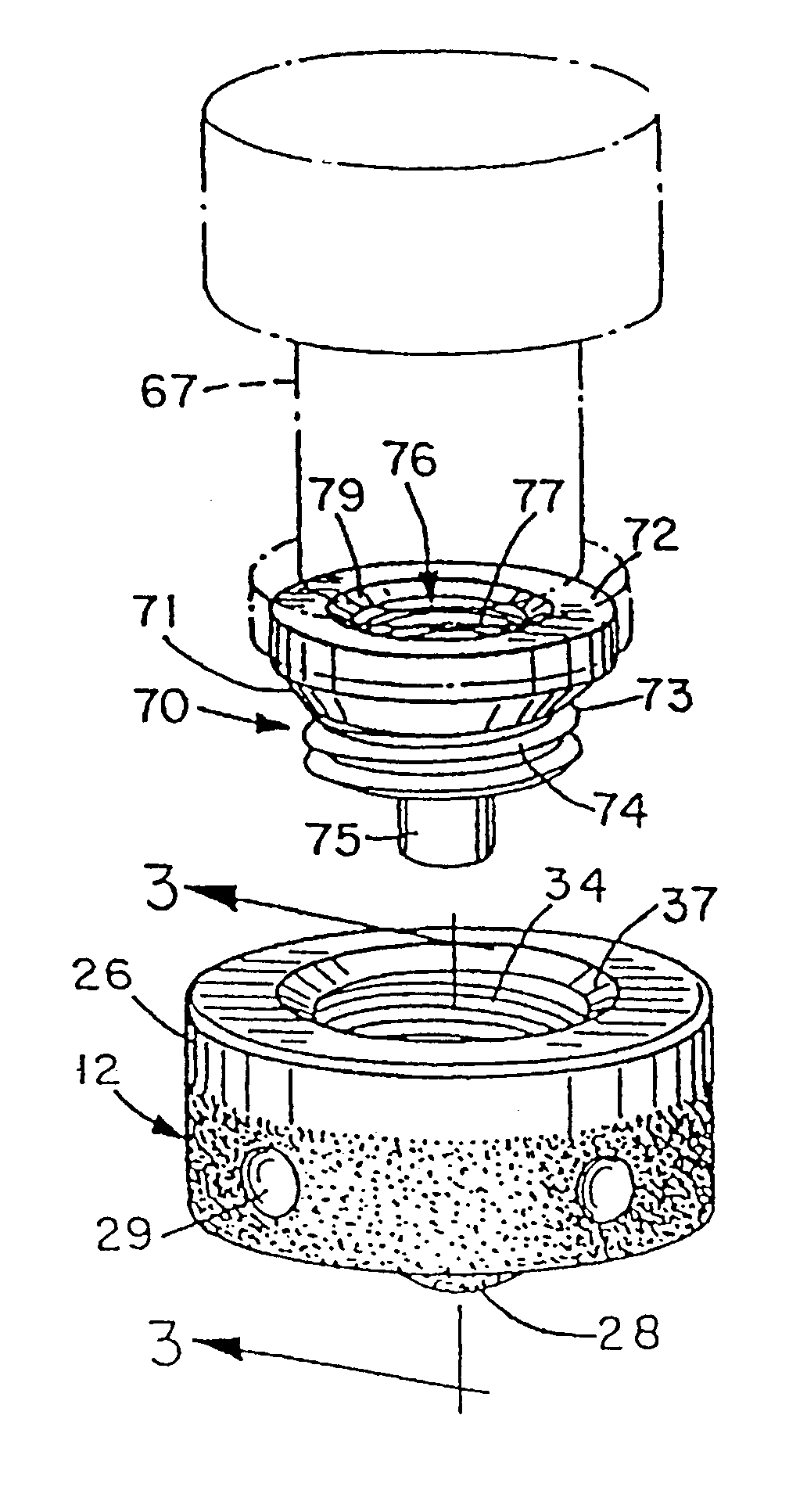

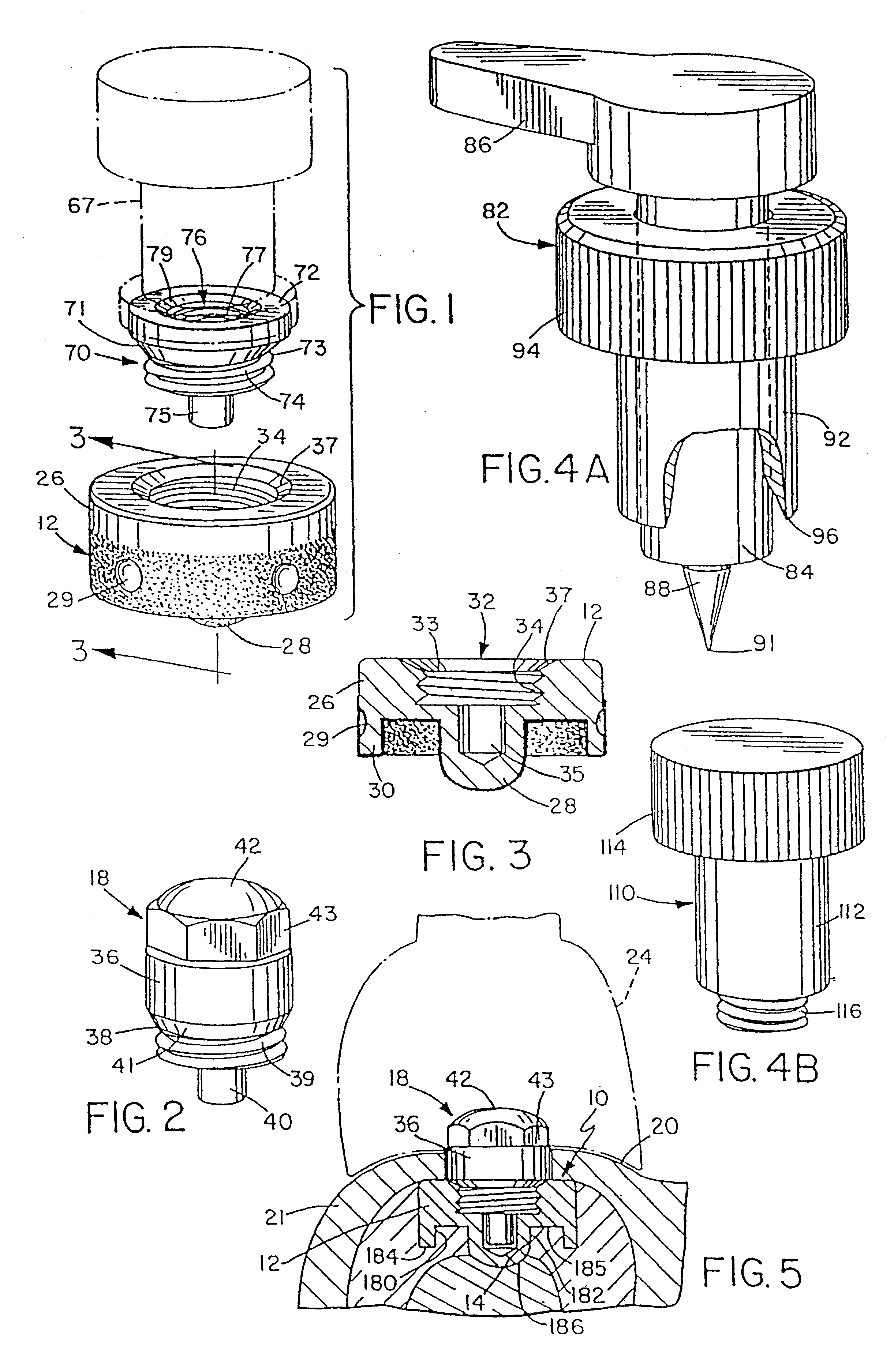

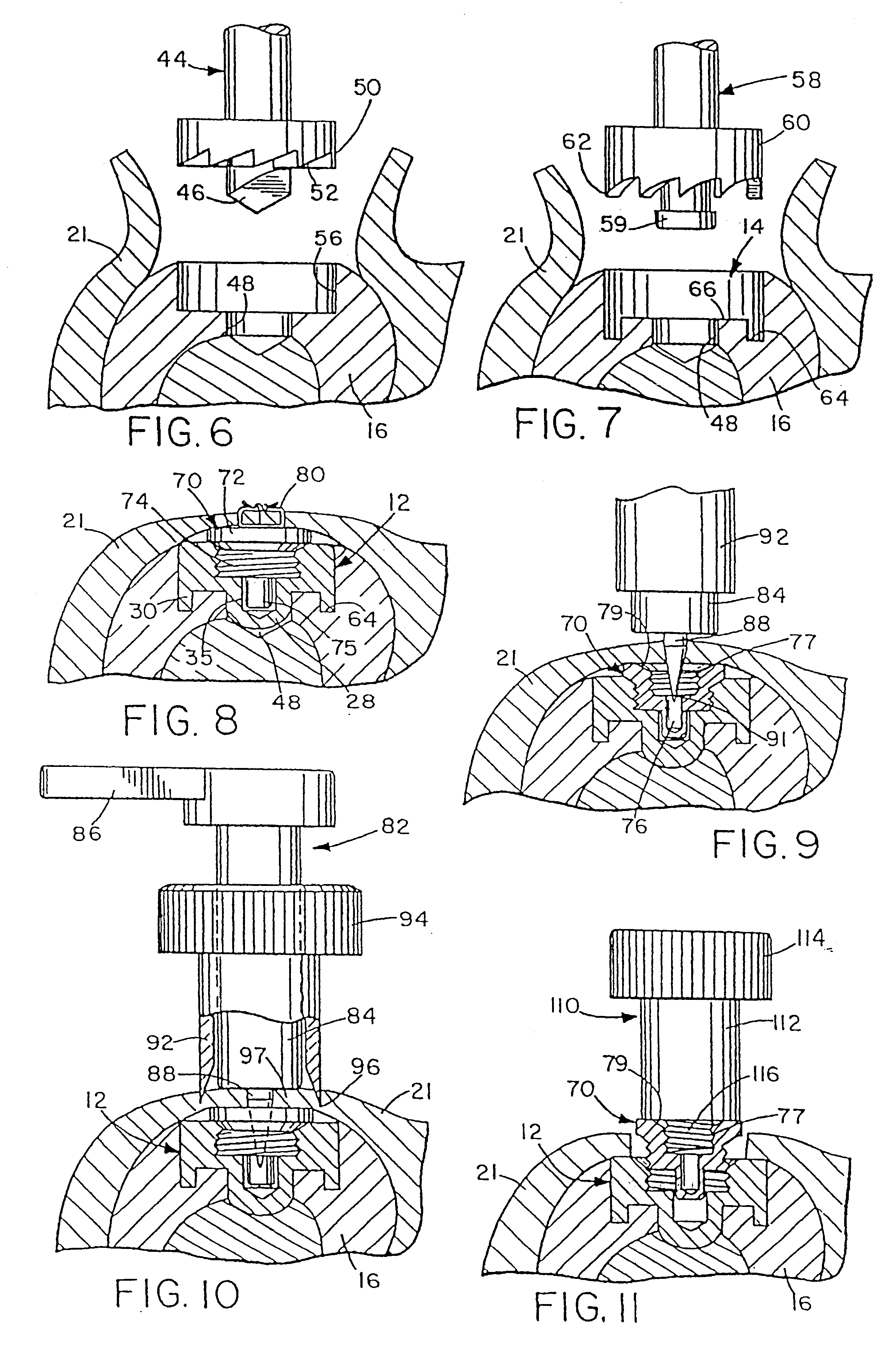

first embodiment

Healing screw 182 has a relatively short head portion 195 and a downwardly depending, screw threaded shaft portion 196 for mating engagement in the bore 192 of implant member 180, as illustrated in FIG. 18. The undersurface of head portion 195 seats in recessed area 190 and has a tapered annular surface portion 197 for seating on taper 191 around the recessed area 190, for accurate seating of the screw in bore 192. The upper surface of head 195 has a central, tool receiving bore 198 for receiving the end of a suitable tool for inserting the arrangement in a previously prepared bore in the jawbone, and also for receiving the end of locating tool 82 as described above in connection with the invention. Bore 198 is of hexagonal cross-section, and is designed to be removed by a suitable removal tool having a hexagonal end after location by tool 82.

second embodiment

The rest factor or member of the second embodiment is not illustrated in the drawings but will be similar or equivalent to rest factor 36 as illustrated in FIGS. 2 and 5 of the drawings apart from its lower surface and downwardly depending shaft portion, which will be identical to lower surface and shaft portion of the healing screw 182 for mating engagement in the bore 192 in implant member 180 after osseointegration is complete.

The modified method of inserting insert member 180 in the jaw will now be described with reference to FIGS. 15-17 of the drawings. This procedure can easily be carried out by a dentist, although a dental surgeon may also perform the procedure if desired. After the tissue overlying the implant site has been cut, a pilot dimple is formed at the center of the selected site. The width of the alveolar crest or ridge at the implant site is measured, and the largest possible diameter implant which will fit within the available width while leaving at least 1 / 2 mm o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com