Method for settling of suspensions with use of seepage force and vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments and processing

11. Embodiments and Processing

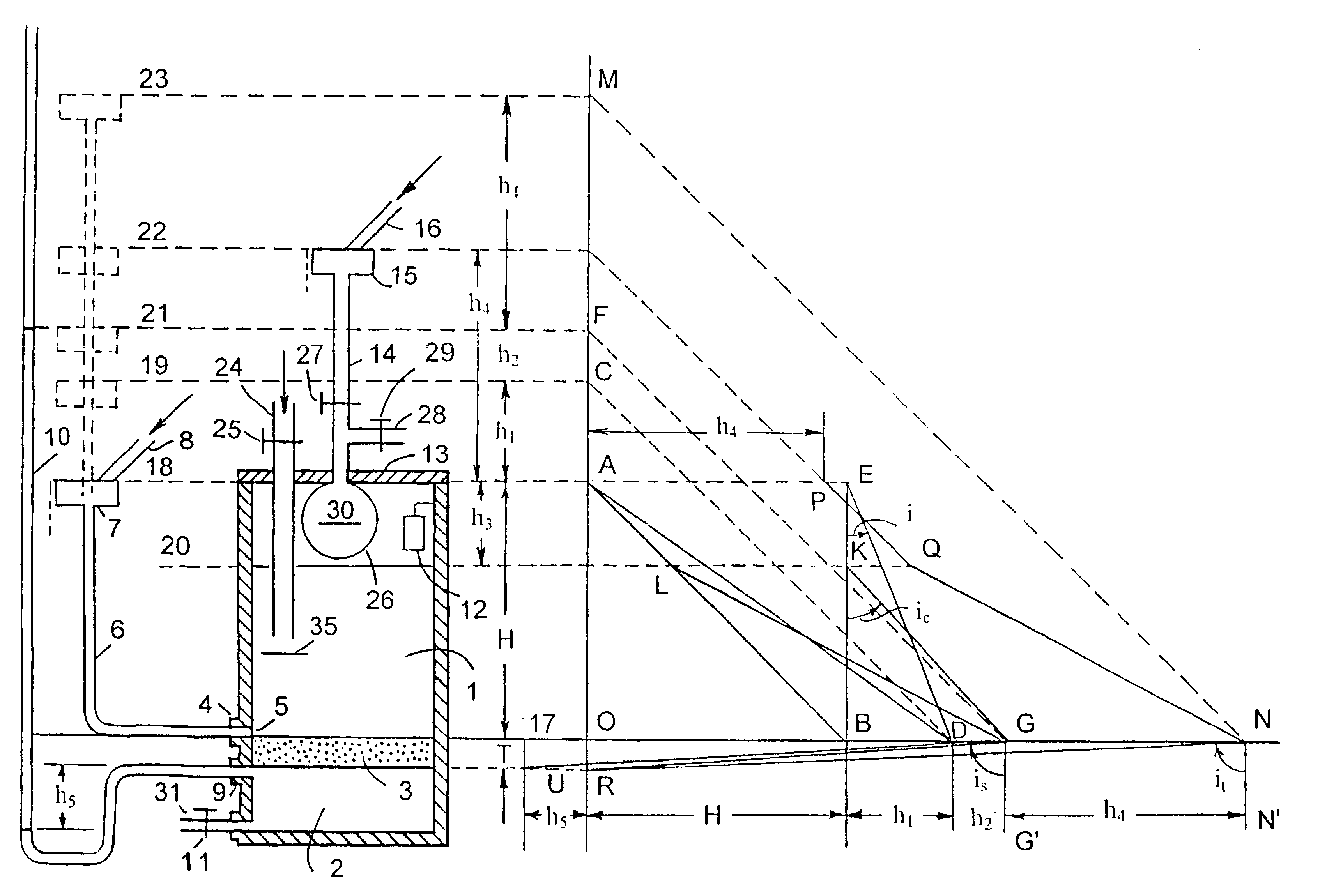

The invention comprises the basic method consisting in application of the seepage force for settling of suspensions or purification of liquids. There are also several supplementary methods as vibrating, diluting, leaving the protecting layer of sediment on the permeable member, increasing the hydrostatic pressure, vacuuming, and isolating the liquid in the closed container from direct contact with water. Combining the basic method with the others, it is possible to find the correct procedure for settling of different types, compositions and states of particular suspensions, and purifying the liquids.

Depending on physical properties of suspensions a number of types of embodiments of the present invention may be implemented, and working regime predetermined based on laboratory and / or pilot experiments. Only principal schemes but not engineering design of different embodiments are shown below. For the sake of clarity and brevity the container 1 will be cal...

first embodiment

The first embodiment is appropriate for suspensions that need an intermediate seepage force for destroying the suspension force.

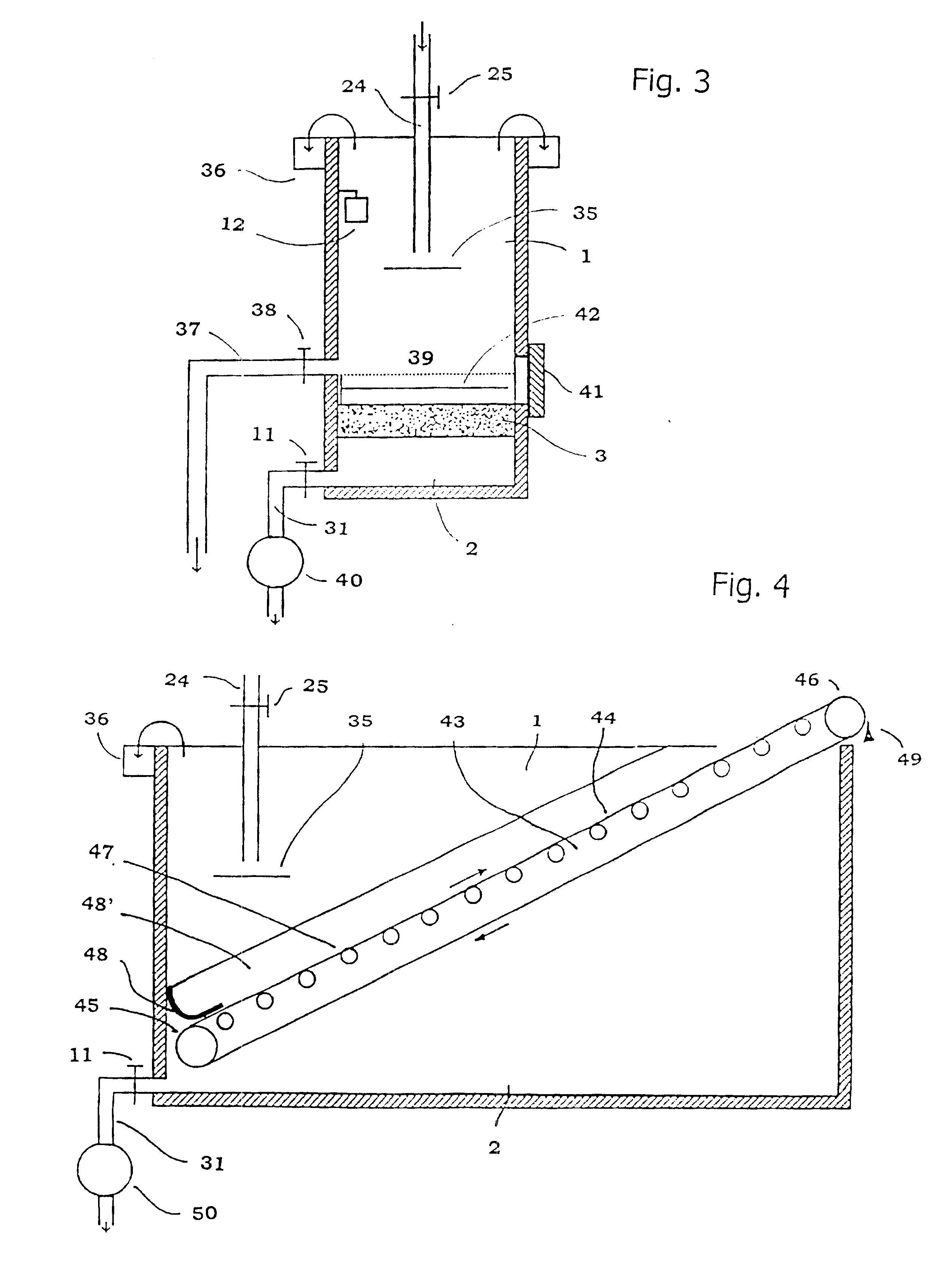

The second possible embodiment of the invention represents an open container where an inclined conveyor 43 wit filtrating belt 44 serves as permeable member 3 (FIG. 4). The idler conveyor pulley 45 is disposed at depth at one end of the container; the driving conveyor pulley 46 is disposed above the container rim at the opposite end. The conveyor belt is rising gradually. The belt is supported by a series of rollers 47. A continuous flexible watertight apron 48 is fastened at face and two longitudinal walls of the container parallel to conveyor belt. The cross-section of the apron designated by 48 is shown at end wall of the container, and the front view designated by 48'--at the longitudinal wall. The apron 48 is placed on the face and sides of the conveyor belt 44 in order to eliminate the passage of suspension by-pass the conveyor belt. The sediment is s...

second embodiment

The second embodiment is appropriate for suspensions needing a low seepage force for destroying the suspension force and has high productivity.

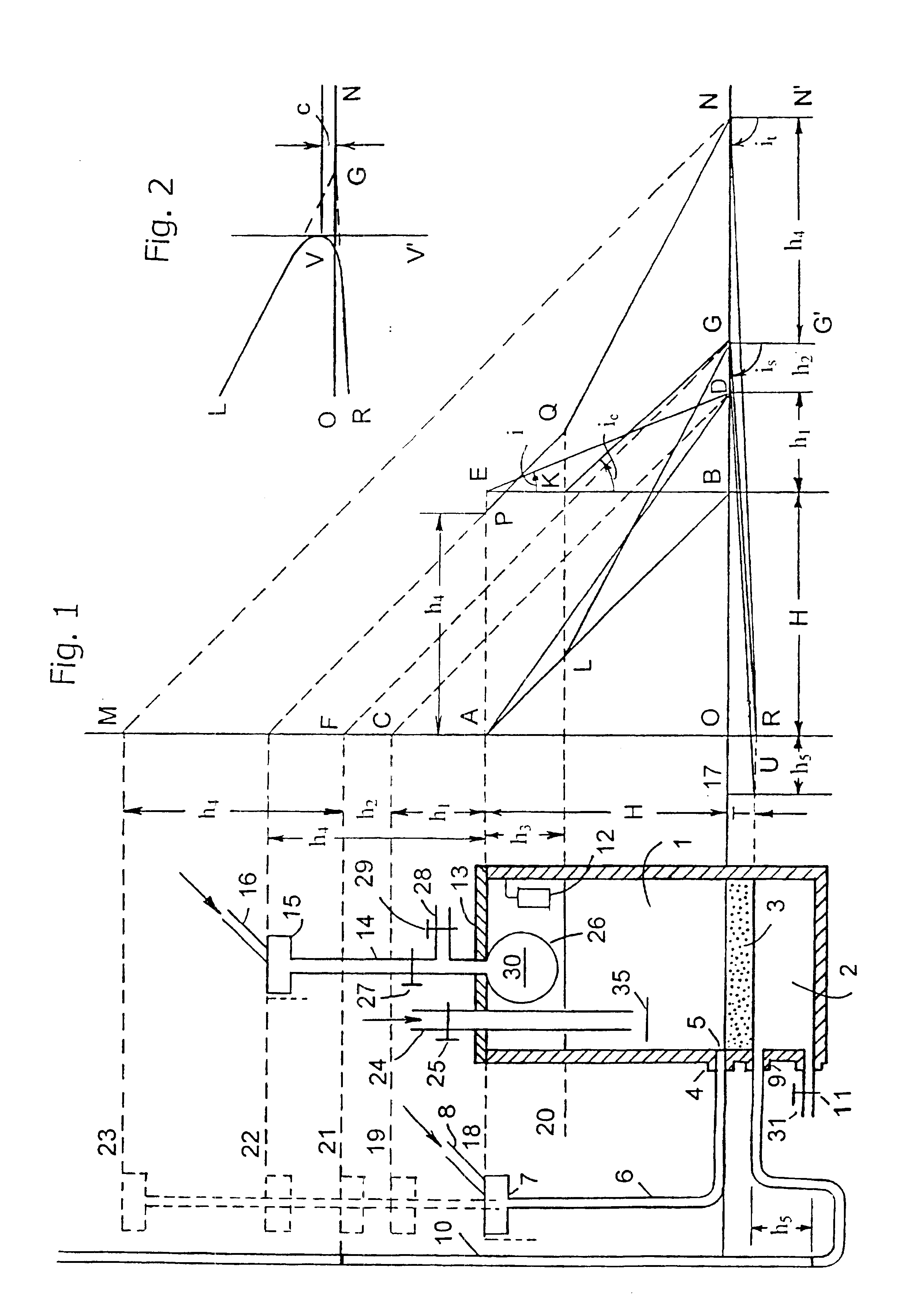

The third possible embodiment represents a closed container (FIG. 5). Three tubes are installed on lid 13: feeding tube 24 with valve 25 and flap 35, pressure tube 14 with outlet 28 and valves 27 and 29, and a short standpipe 51 with valve 52. The suspension is supplied through feeding tube 24. Flap 35 serves for eliminating the vertical jet in the suspension. High hydrostatic pressure is transmitted through tube 14 connected with a conventional pressure tank (not shown in FIG. 5). Outlet 28 with valve 29 serves for removal of supernatant for recycling. Short standpipe 51 with valve 52 serves for communication with atmosphere. A discharging outlet 37 with valve 38 is disposed at the middle part of closed container at a certain height above permeable member 3 (level 39, shown by a dotted line) as that in the first embodiment. Vibrator 12 is in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com