Liquid crystal display device and manufacturing method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

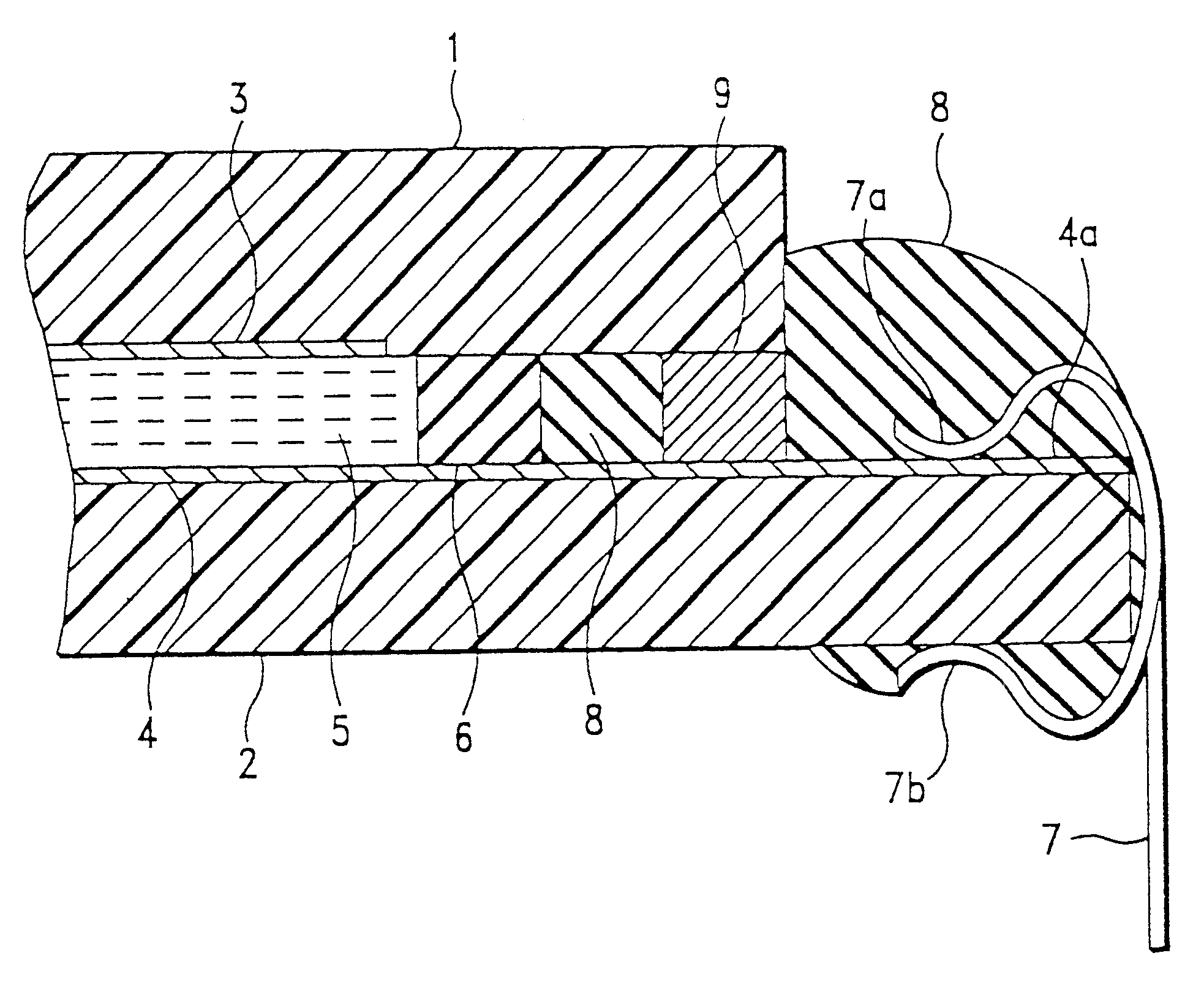

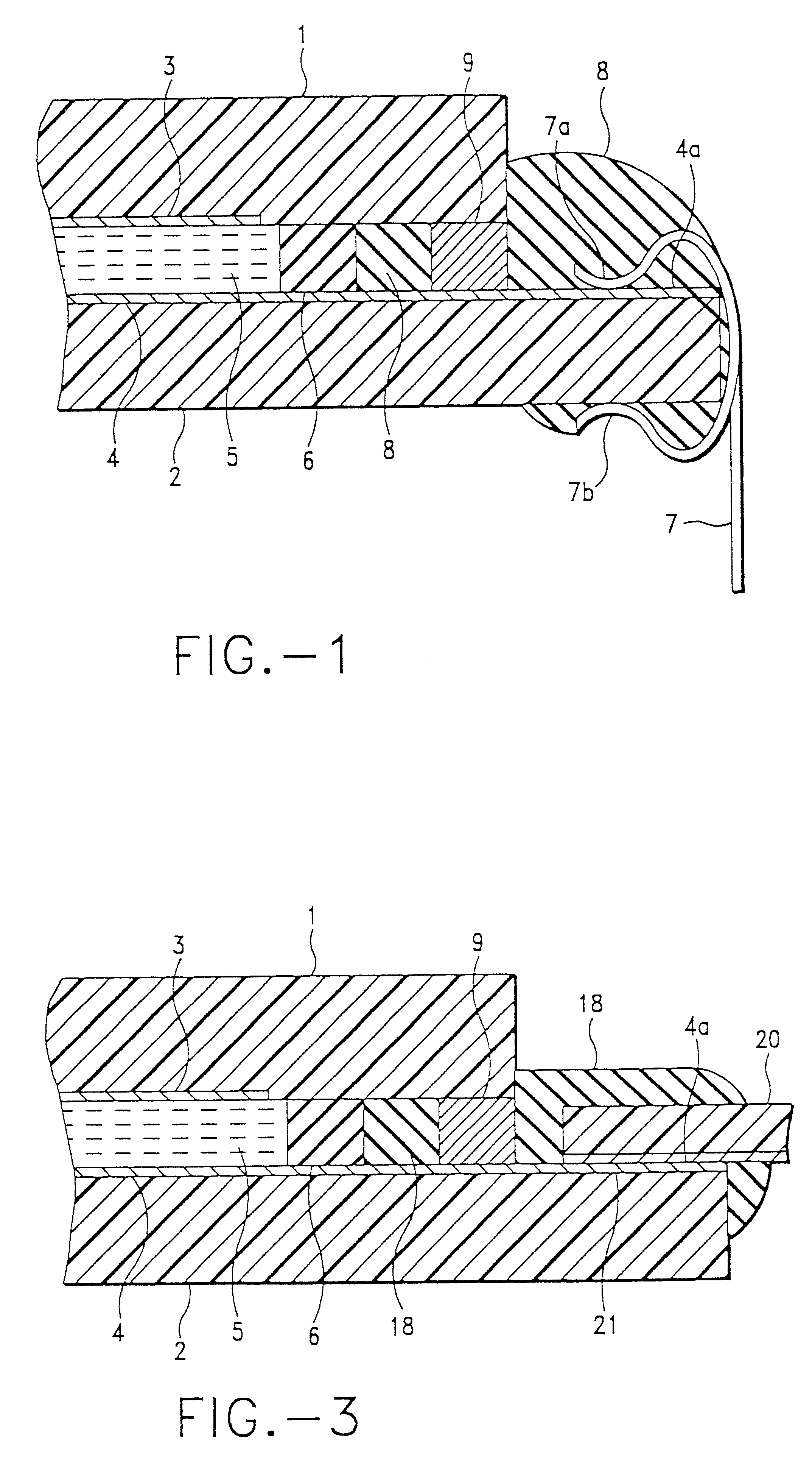

FIG. 1 shows an enlarged partial cross-sectional view of the first embodiment of the liquid crystal display device related to the invention. In this embodiment, the liquid crystal display device is provided with top substrate 1 formed in the same way as the conventional example described above, bottom substrate 2, transparent electrodes 3 and 4. Liquid crystal layer 5, seal material 6, and electrode pads 4a. Insertion pins 7 with legs are installed on electrode pads 4a of bottom substrate 2 and are then fastened with molding material 8. Depending on the liquid crystal display method, a polarizing plate may be positioned on the outside of the top and bottom substrates.

In this embodiment, support columns 9 formed using a conductive ink containing carbon particles are formed between the edges of top substrate 1 and bottom substrate 2. As will be explained below, these support columns 9 are formed simultaneously with the assembly of the top and bottom substrates before mold material 8 i...

second embodiment

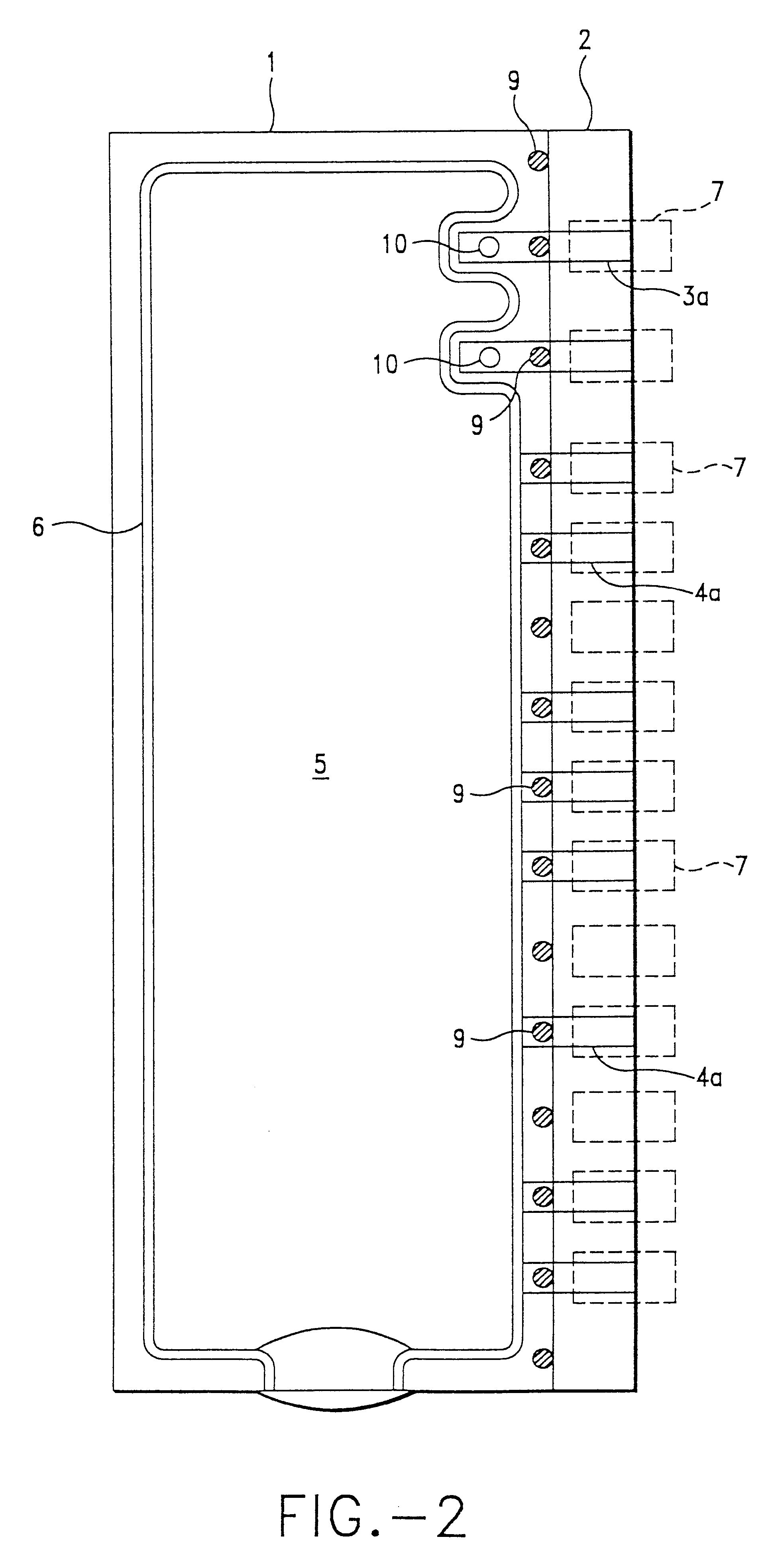

FIG. 3 shows the second embodiment of the liquid crystal display device related to the invention. In the second embodiment, top substrate 1, bottom substrate 2, transparent electrodes 3 and 4, electrode pads 4a, liquid crystal layer 5, seal material 6, and support columns 9 are identical to those in the above embodiment, and thus their explanations are omitted.

In this embodiment, heat seal 20 is adhered to the top of multiple and parallel electrode pads 3a (connected to transparent electrode 3; FIG. 6) and 4a. In heat seal 20, wiring pads 21 are formed on the bottom of a thin flexible resin sheet at the same pitch as that of electrode pads 3a and 4a, and an anisotropic conductive layer (not shown in the figure) is adhered to the surface of wiring pads 21. This anisotropic conductive layer is produced by dispersing conductive particles in a thermohardening resin, for example, and adhesion with appropriate heating and pressurization can produce conductivity in the adhesion direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com