Liquid sample dispensing methods for precisely delivering liquids without crossover

a liquid sample and liquid technology, applied in the field of liquid sample dispensing, can solve the problems of intra-sample carryover or contamination of reusable probes used to deliver liquid aliquots from successive containers such as tubes or liquid reagent vessels, and the liquid tends to remain on the exterior surface of the pipette, so as to reduce the amount of aspirated liquid. , the effect of minimizing the amount of aspirated liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

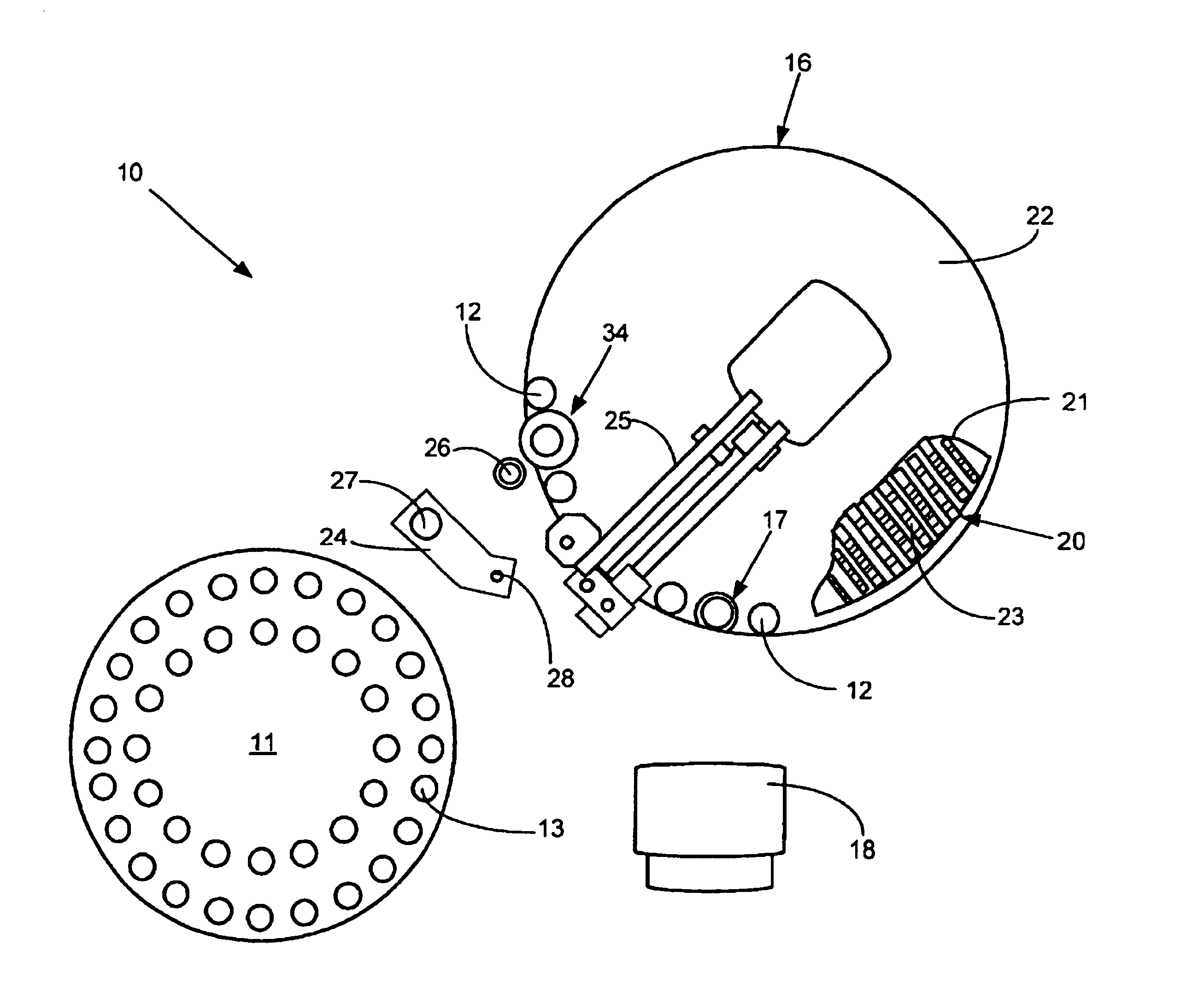

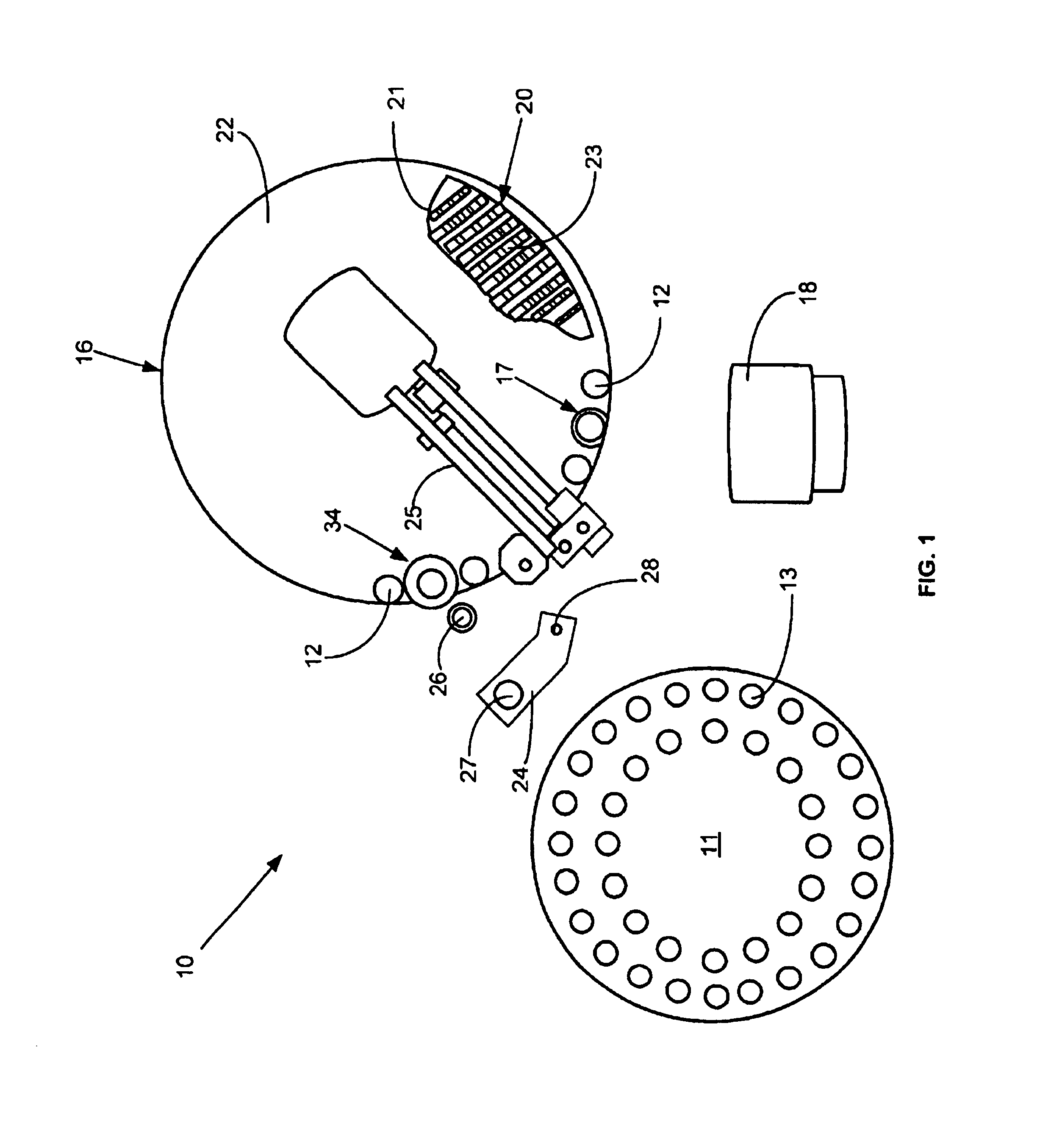

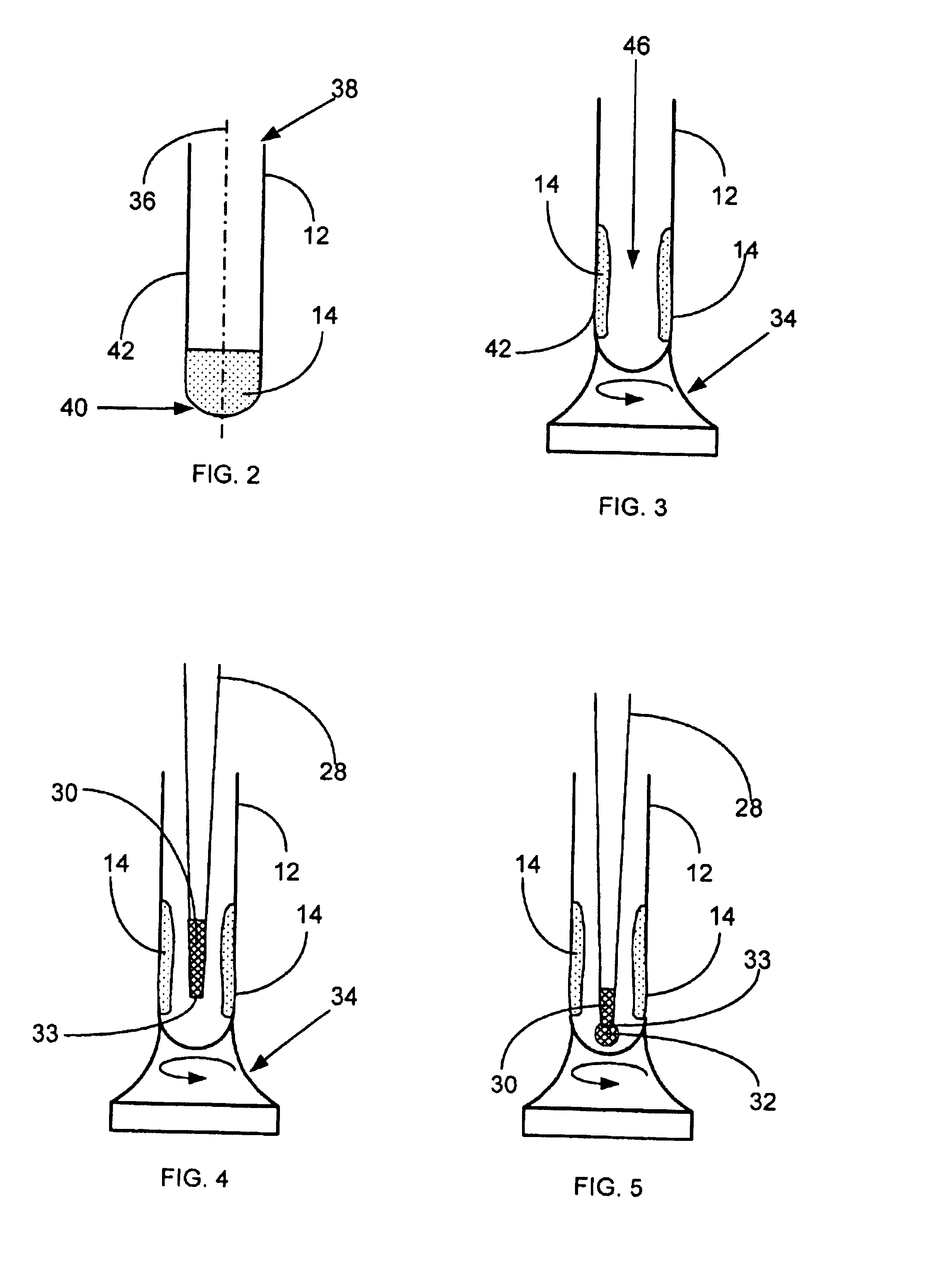

[0026]The method and apparatus of this invention will be described initially with particular reference to FIG. 1 of the drawings. FIG. 1 shows schematically the elements of a conventional automatic chemical analyzer 10 comprising a sample cup carousel 11 supporting a plurality of open sample tubes 13, a test vessel carousel 14, adapted to hold a plurality of test vessels 12 and to provide plurality of reagent liquid cartridges 20, illustrated as disposed beneath a cut out portion 21 of a lid 22, which covers various thermally controlled compartments. The vessel carousel 14, preferably in the form of a wheel, has about one hundred separate open cavities 17 for holding vessels 12, the inner wall of each cavity having an opening to allow transmission of light. Vessels 12 are seen in FIG. 2 as having a generally cylindrically shape around a central axis 36, also having an open top 38 and a closed bottom 40. Test vessel carousel 14 is provided with means 34 for rotating selected ones of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com