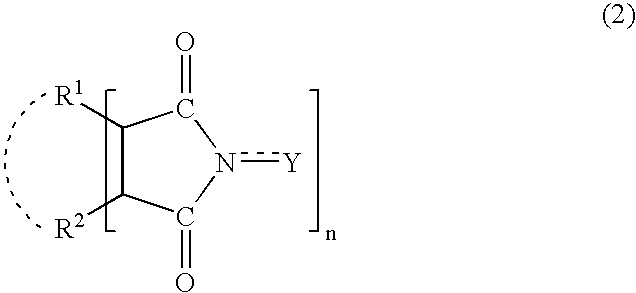

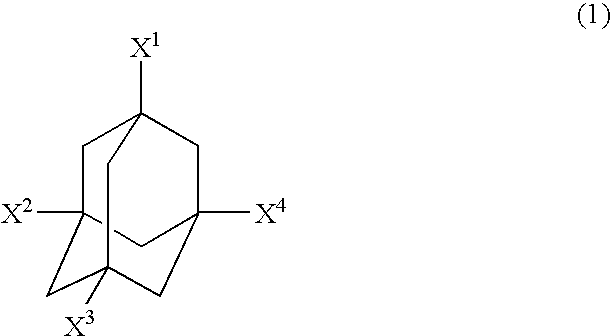

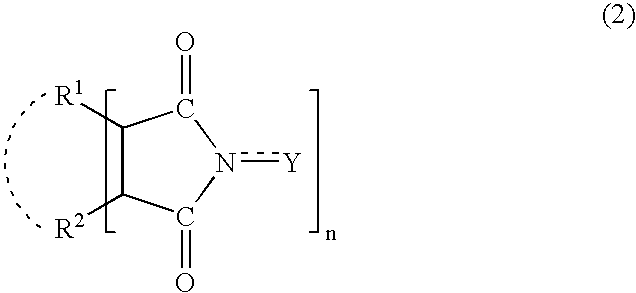

Adamantane derivatives and process for producing them

a technology of adamantane and derivatives, which is applied in the direction of organic compounds/hydrides/coordination complexes, organic chemistry, physical/chemical process catalysts, etc., can solve the problems of difficult introduction of hydroxyl groups (specifically, a plurality of hydroxyl groups) to adamantane by using these processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0227]Mixture of 10 mmole 1-acetylaminoadamantane (Aldrich chemical Company, Inc.), 1 mmole of N-hydroxyphthalimide (NHPI), 0.05 mmole of vanadium (III) acetylacetonato (V(AA)3) and 25 mL of acetic acid was stirred under an oxygen atmosphere and the conditions represented in Table 1 (temperature and time). The products in the reaction mixture were analyzed by gas chromatography, and, as a result, 1-acetylamino-3-adamantanol (compound 1), 1-acetylamino-3,5-adamantanediol (compound 2) and 1-acetylamino-4-adamantanone (compound 3) were obtained with conversions and yields represented in Table 1.

[0228]

TABLE 1TemperatureTimeConversionYield (%)(° C.)(hr)(%)Comp.1Comp.2Comp.3756896416860209266194Comp.1 (compound 1): 1-acetylamino-3-adamantanol Comp.2 (compound 2): 1-acetylamino-3,5-adamantanediol Comp.3 (compound 3): 1-acetylamino-4-adamantanone

example 2

[0229]A reactor was charged with 10 mmole of adamantane, 1 mmole of NHPI, 0.005 mmole of Co(AA)2 and 25 mL of acetic acid, then equipped with a gas bag of mixed gas (a mixed gas of 2 L of carbon monoxide and 0.5 L of oxygen). The resultant mixture was stirred for 6 hours at a temperature of 60° C. to give 1-carboxyadamantane and 1,3-dicarboxyadamantane.

[0230]A mixture of 10 mmole of 1-carboxyadamantane, 1 mmole of NHPI, 0.05 mmole of V(AA)3 and 25 mL of acetic acid was stirred under an oxygen atmosphere and the conditions represented in Table 2 (time and temperature). As a result, 1-carboxy-3-adamantanol (compound 1), 1-carboxy-3,5-adamantanediol (compound 2) and 1-carboxy-4-adamantanone (compound 3) were obtained with conversions and yields represented in Table 2.

[0231]

TABLE 2TemperatureTimeConversionYield (%)(° C.)(hr)(%)Comp.1Comp.2Comp.3751644483752785912475590641947589452295Comp.1 (compound 1): 1-carboxy-3-adamantanol Comp.2 (compound 2): 1-carboxy-3,5-adamantanediol Comp.3 (co...

example 3

[0232]In the presence of an acid catalyst (p-toluenesulfonic acid), 1-carboxyadamantane obtained in Example 2 was allowed to react with an excess amount of ethanol to give 1-ethoxycarbonyladamantane.

[0233]A mixture of 10 mmole of the 1-ethoxycarboxyadamantane, 1 mmole of NHPI, 0.05 mmole of V(AA)3 and 25 mL of acetic acid was stirred under an oxygen atmosphere and the conditions represented in Table 3 (temperature and time). As a result, 1-ethoxycarbonyl-3-adamantanol (compound 1), 1-ethoxycarbonyl-3,5-adamatanediol (compound 2) and 1-ethoxy-4-carbonyladamantanone (compound 3) were obtained with conversions and yields represented in Table 3.

[0234]

TABLE 3TemperatureTimeConversionYield (%)(° C.)(hr)(%)Comp.1Comp.2Comp.375695581687538668676066348646020925416775159927435Comp.1 (compound 1): 1-ethoxycarbonyl-3-adamantanol Comp.2 (compound 2): 1-ethoxycarbonyl-3,5-adamantanediol Comp.3 (compound 3): 1-ethoxycarbonyl-4-adamantanone

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com