Object observation apparatus and object observation

a technology of object observation and object beam, which is applied in the direction of material analysis, instruments, heat measurement, etc., can solve the problem that conventional apparatuses are difficult to realize high-precision observation of objects using electron beams, and achieve high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]An embodiment of the present invention will be described with reference to the accompanying drawings. The same reference numerals denote the same parts throughout the drawings, and a repetitive description thereof will be omitted.

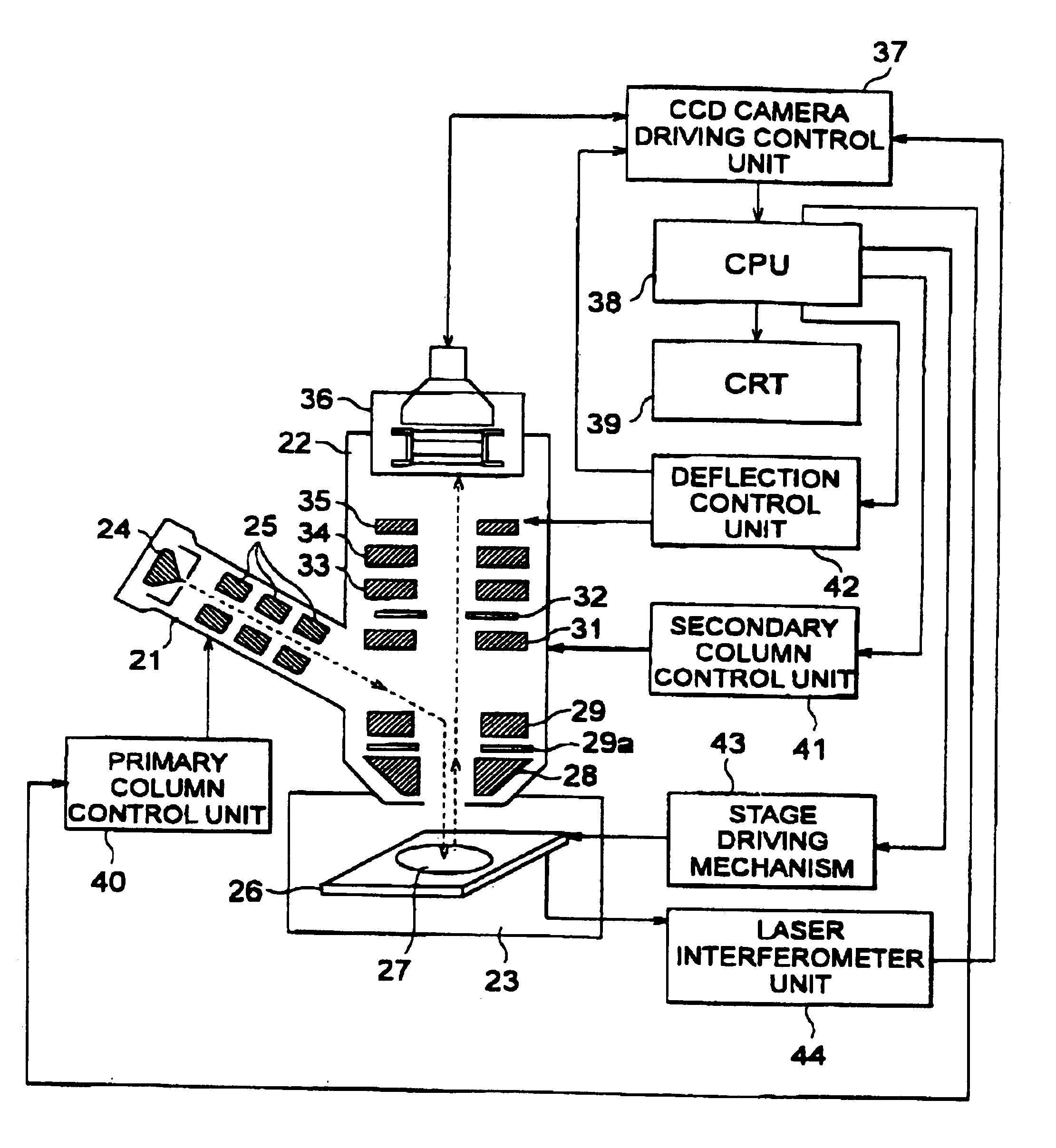

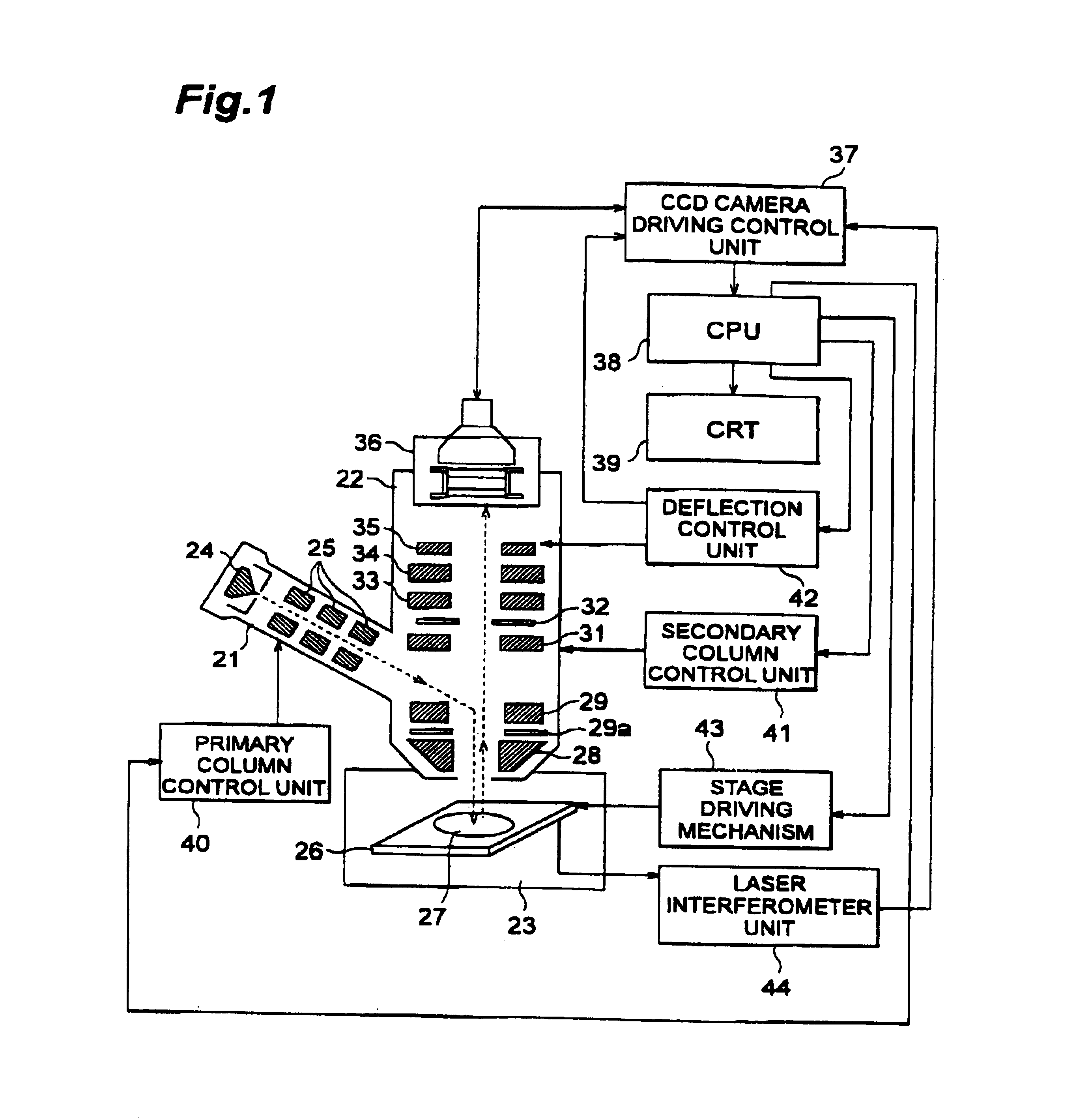

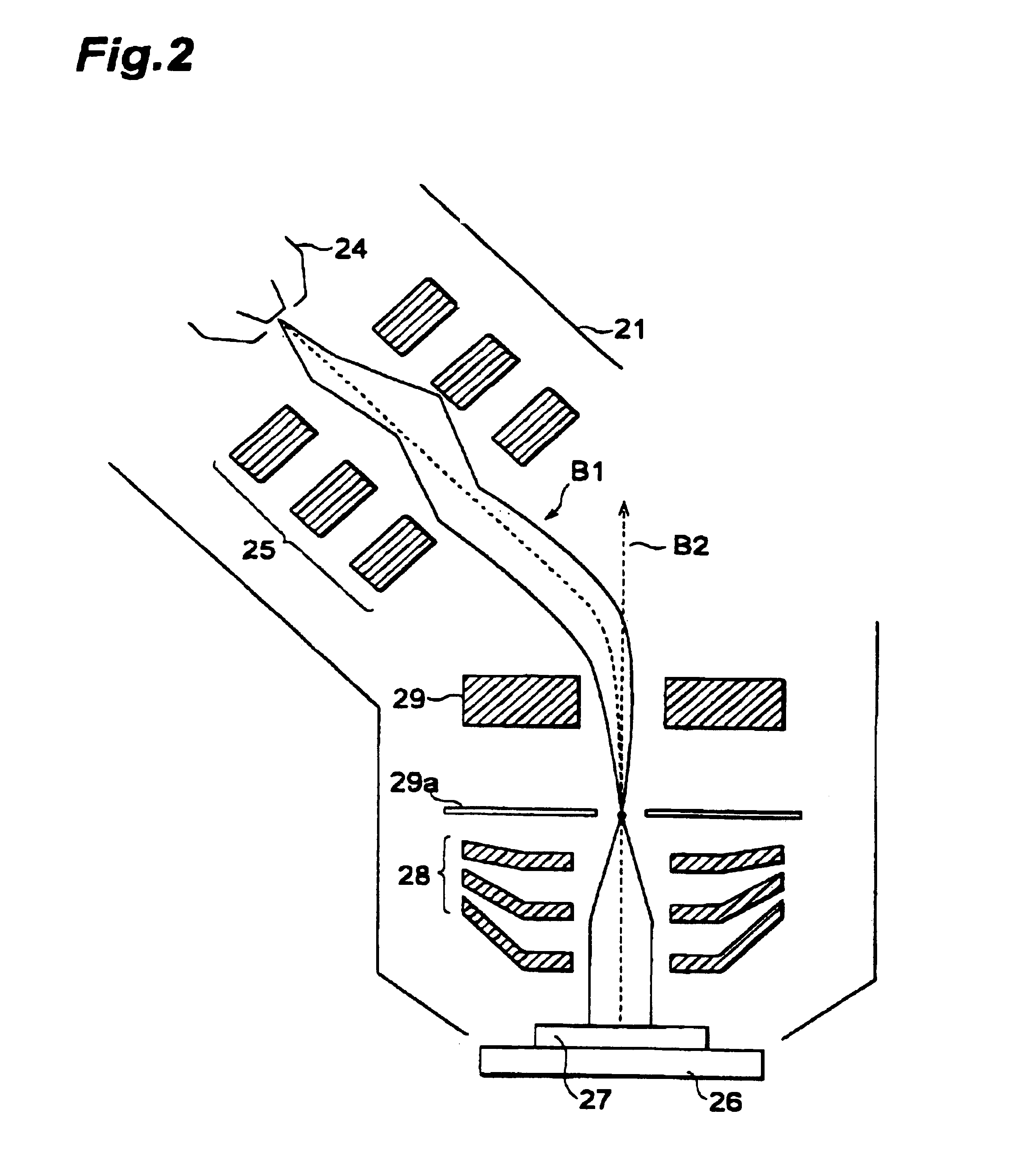

[0025]FIG. 1 is a view showing the whole arrangement of the embodiment. FIG. 2 is a view showing the structure of a primary column and the orbit of a primary beam. FIG. 3 shows views of the structure of an electrostatic lens in the primary column. FIG. 4 is a view showing the orbit of a secondary beam in a secondary column.

[0026]As shown in FIG. 1, an observation apparatus comprises a primary column 21, secondary column 22, and chamber 23.

[0027]The primary column 21 is diagonally connected to the side surface of the secondary column 22, and the chamber 23 is located below the secondary column 22.

[0028]The primary column 21 incorporates an electron gun 24. A primary optical system 25 is located on the optical path of an electron beam (primary beam) emi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pattern size | aaaaa | aaaaa |

| pattern size | aaaaa | aaaaa |

| acceleration voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com