Patents

Literature

149results about How to "Promote decomposition and ablation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System for treating hydraulic oil by magnetization, centrifugation and electric shock hammer absorption and magnetic field rotation

InactiveCN105952718ASimple structureReduce volumePump assembliesFluid-pressure actuator componentsMagnetElectricity

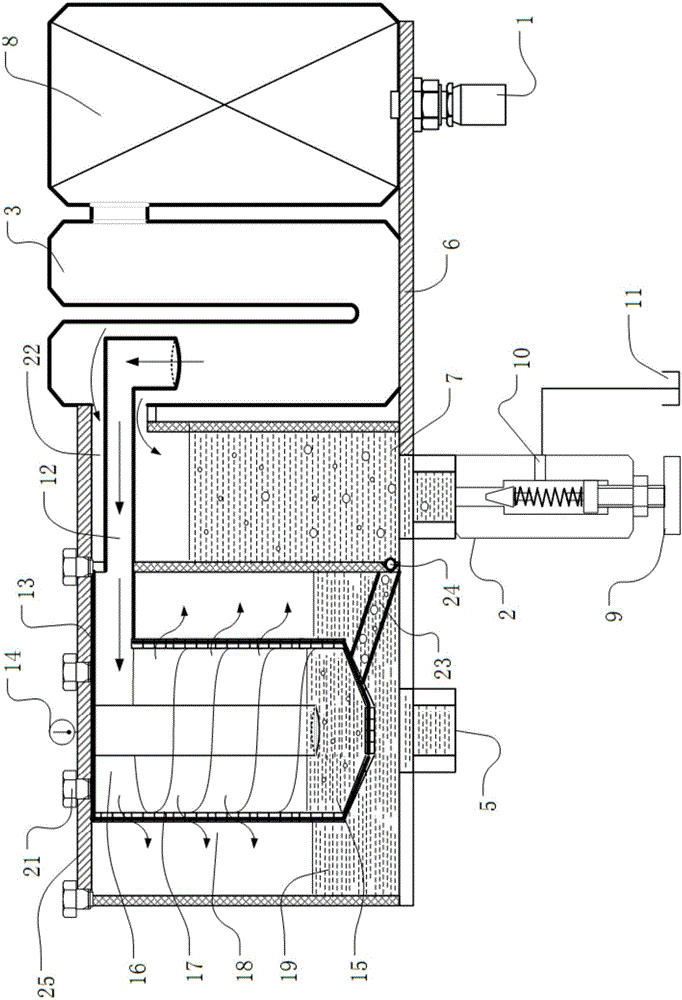

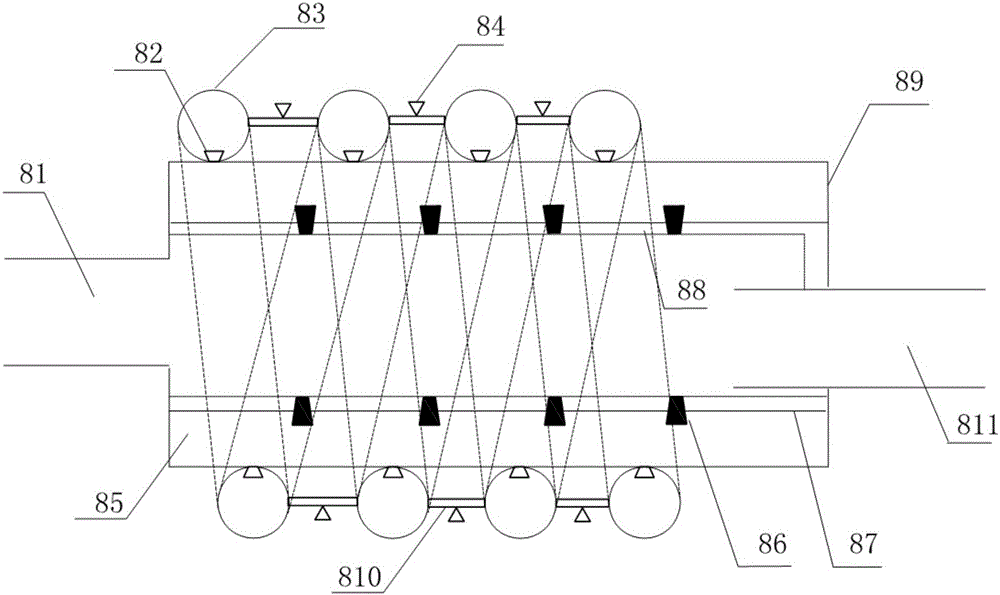

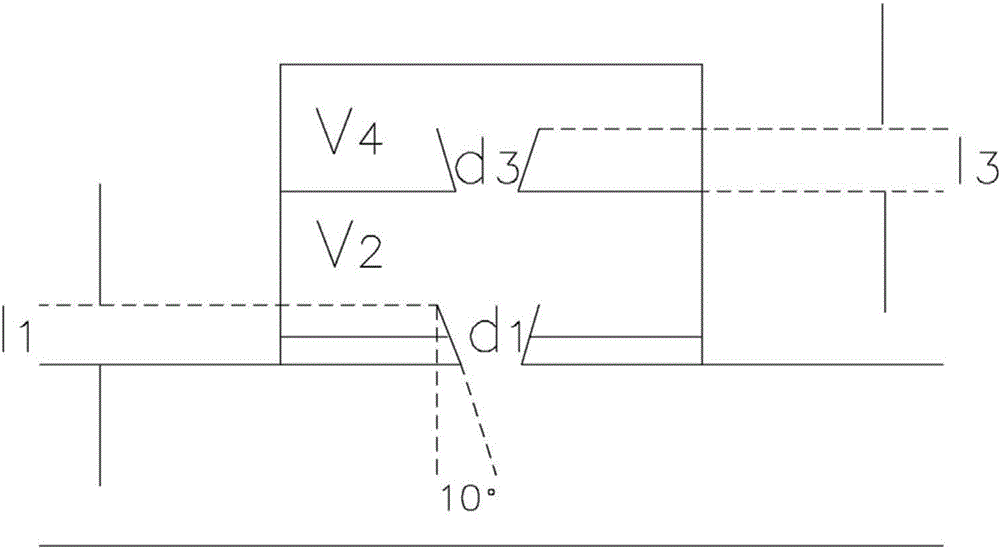

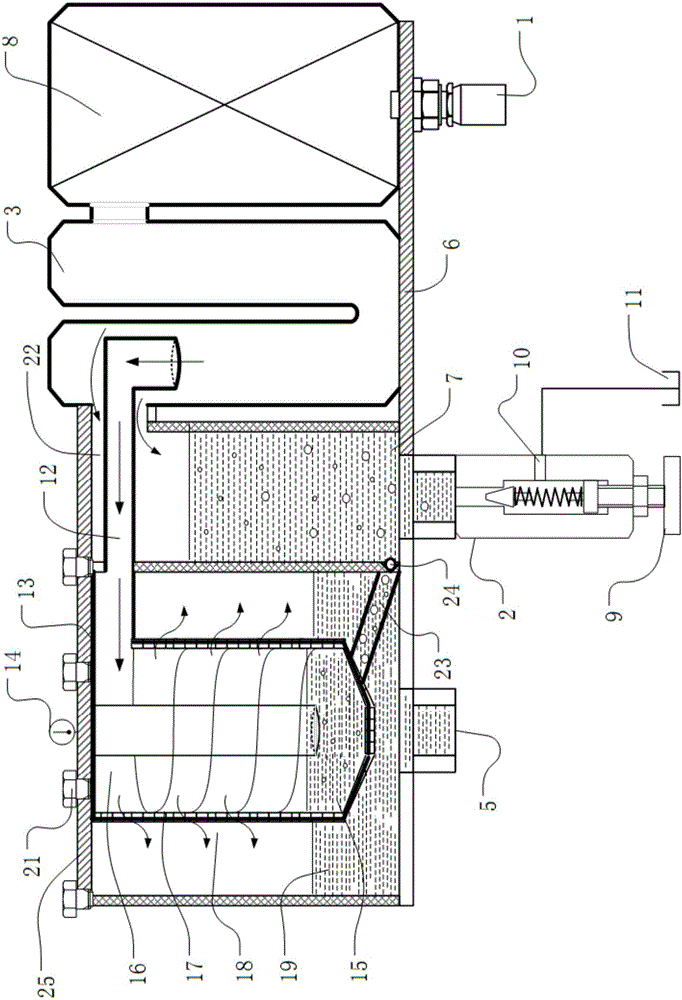

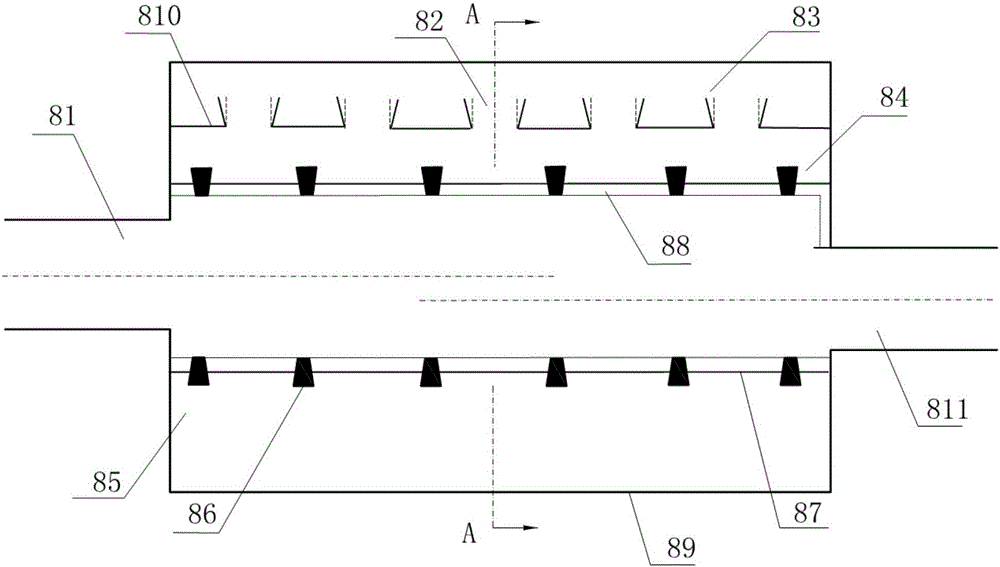

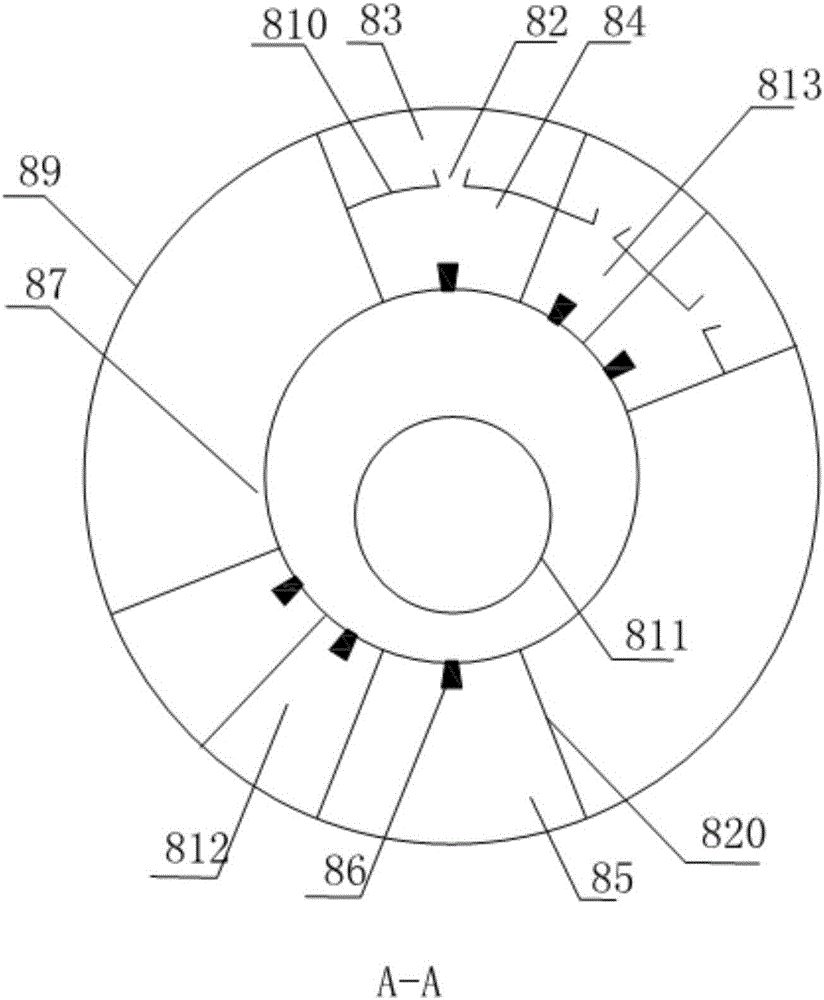

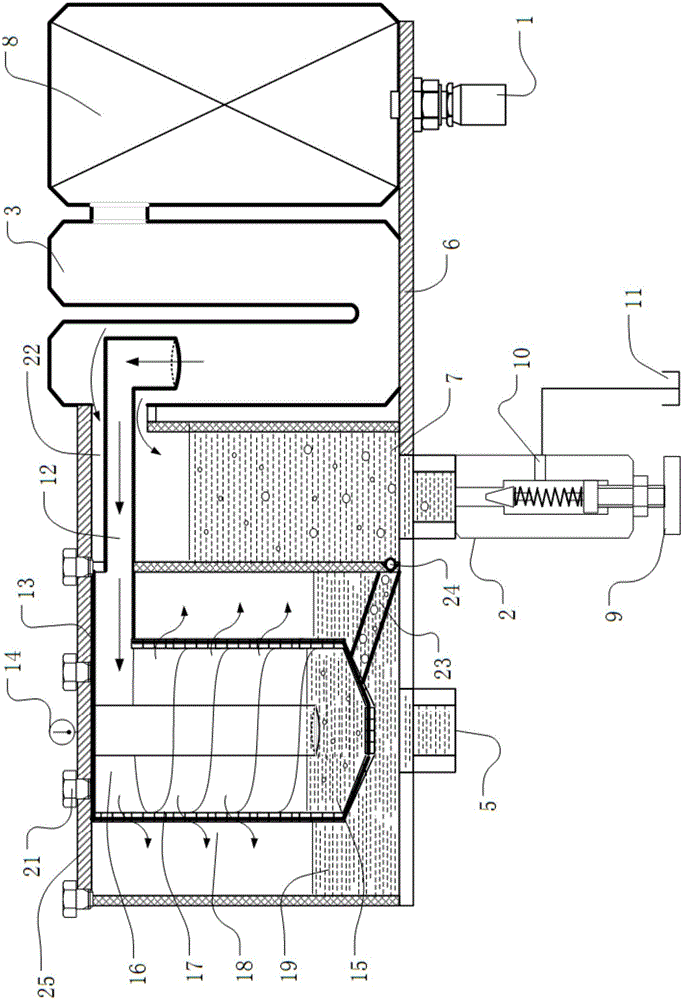

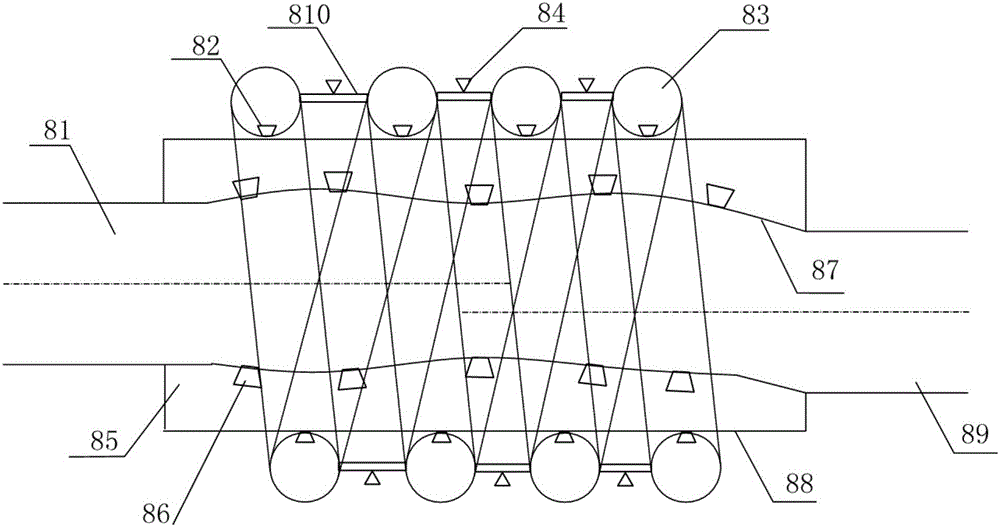

The invention relates to a system for treating hydraulic oil by magnetization, centrifugation, electric hammer adsorption and rotating magnetic field. The oil tank is provided with a filter box, a permanent magnet, a partition and a heater in sequence; the first oil return pipe is inserted into the oil tank, and the A cooler and a temperature sensor are provided; one end of the second oil return pipe is connected to the first oil return pipe, and the other end extends into the filter box; the U-shaped pipe is sequentially installed with a magnetizing device, a centrifugal device, a first adsorption device, a rotating magnetic field device and a second 2. Adsorption device; the top of the filter box is equipped with a defoaming plate inclined downwards; the surface of the defoaming plate is laid with a layer of magnetic metal mesh; the oil suction pipe is inserted into the oil tank body, and an oil filter, a degausser and a residual magnetic sensor are arranged on it; Both the first and second adsorption devices adopt the same polarity adjacent adsorption rings with electric hammers. The invention combines mechanical, electric, magnetic and other technologies to make solid particles gather on the tube wall for adsorption, and air is separated or ablated. It has simple structure, low cost and strong oil purification ability.

Owner:SHAOXING UNIVERSITY

Filtering device adopting wave suppression, electrification, separation and adsorption

InactiveCN105909616ANo vibrationExtended service lifeFluid-pressure actuator componentsElectricitySelf adaptive

The invention relates to a filtering device adopting wave suppression, electrification, separation and adsorption. A filter, a U-shaped particle separating module, an oil return barrel and an outer barrel of the filtering device are sequentially mounted on a bottom plate. The filter is connected with the U-shaped particle separating module, and the working-condition self-adaptive wave suppression filter is adopted. The U-shaped particle separating module comprises a U-shaped pipe which is sequentially provided with an electrification module, a separation module, adsorption modules and a demagnetization module. The upper portion of the U-shaped particle separating module and the upper portion of the oil return barrel are connected through an oil return barrel oil inlet pipe. An inner barrel is arranged in the outer barrel and mounted on an end cover through a top plate and a plurality of bolts. A spiral flow channel is accommodated in the inner barrel and connected with the U-shaped particle separating module through an inner barrel oil inlet pipe. The inner barrel oil inlet pipe is located in the oil return barrel oil inlet pipe and extends into the center of the U-shaped particle separating module, and a filter element is arranged on the inner wall of the inner barrel. The filtering device has the advantages of being good in filtering performance, high in adaptability and integration, long in service life and the like.

Owner:SHAOXING UNIVERSITY

Oil filtering method adopting magnetization, adsorption, rotating magnetic field and centrifuging and used for hydraulic system

InactiveCN105889223AExtended service lifeReduce filtering cost and complexityFluid-pressure actuator componentsFuel tankSpiral flow

The invention relates to an oil filtering method adopting magnetization, adsorption, a rotating magnetic field and centrifuging and used for a hydraulic system. According to the oil filtering method, a U-shaped particle separation module is used for achieving separation of solid particles so that the solid particles in oil liquid can move towards the pipe wall, at the position of an outlet of the U-shaped particle separation module, oil liquid, rich in solid particle, nearby the pipe wall flows back to an oil tank after entering an oil return barrel through an oil inlet pipe of an oil return barrel module, oil liquid, containing a micro quantity of small-particle-size particles, at the center of a pipeline enters an inner barrel through an oil inlet pipe of the inner barrel to be subjected to high-precision filtering, the service life of a filter element is prolonged, and the filtering cost is reduced; the oil liquid entering the oil inlet pipe of the inner barrel flows into a spiral flow channel of the inner barrel in a tangent inflow manner, the inner barrel wall is provided with the filter element, filter liquor is closely attached to the filter element to flow under the effect of centrifugal force, the filter liquor fast flows parallel to the surface of the filter element, and filtered hydraulic oil flows out to an outer barrel in the direction perpendicular to the surface of the filter element; and pollution particles deposited at the bottom of the inner barrel are discharged to the oil return barrel through an electronic control check valve, and the service life of the filter element is prolonged.

Owner:王雅莉

Filtering method adopting magnetization, adsorption and rotating magnetic field for hydraulic system

InactiveCN105909615AExtended service lifeIncreasing the thicknessMagnetic separationFluid-pressure actuator componentsMagnetizationSolid particle

The invention relates to a filtering method adopting magnetization, adsorption and a rotating magnetic field for a hydraulic system. Separation of solid particles is achieved through a U-shaped particle separating module, and the solid particles in oil are made to move to the pipe wall; at an outlet of the U-shaped particle separating module, the oil which is rich in the solid particles and near the pipe wall enters an oil return barrel through an oil return barrel oil inlet pipe and then flows back into an oil tank, and the oil which contains trace of small-diameter particles and is located in the pipe center enters an inner barrel through an inner barrel oil inlet pipe to be subjected to high-precision filtering, so that the service life of a filter element is prolonged, and the filtering cost and complexity are lowered; the oil entering the inner barrel oil inlet pipe flows into a spiral flow channel of the inner barrel in a tangential inflow mode, the inner barrel wall is used as the filter element, filter liquor flows by tightly attaching the filter element under the effect of centrifugal force, the filter liquor quickly flows in parallel to the surface of the filter element, and the filtered hydraulic oil flows out to an outer barrel in the direction perpendicular to the surface of the filter element; and polluting particles deposited at the bottom of the inner barrel can be discharged to the oil return barrel through an electrically operated check valve, so that the service life of the filter element is prolonged.

Owner:张国云

Filtering device adopting work condition self-adaptive filtering, magnetizing and adsorbing

InactiveCN105864169ANo vibrationExtended service lifeServometer circuitsFluid-pressure actuator componentsSelf adaptiveParticle separation

The invention relates to a filter device adopting working condition self-adaptive filtering, magnetization and adsorption. The filter, U-shaped particle separation module, oil return cylinder and outer barrel are sequentially placed on the bottom plate; the filter is connected to the U-shaped particle separation module. The U-shaped particle separation module includes a U-shaped tube, and the U-shaped tube is sequentially installed with a temperature control module, a magnetization module, an adsorption module, and a degaussing module; the U-shaped particle separation module and the oil return cylinder pass through an oil return cylinder oil inlet pipe Connection; the inner cylinder is placed in the outer barrel, which is installed on the end cover through a top plate and several bolts; the spiral flow channel is accommodated in the inner cylinder, and it is connected with the U-shaped particle separation module through an inner cylinder oil inlet pipe; The barrel oil inlet pipe is located in the oil return barrel oil inlet pipe and extends into the center of the U-shaped particle separation module; the filter element is arranged on the inner wall of the inner barrel; the bottom of the outer barrel is provided with a hydraulic oil outlet. The invention has many advantages such as good filtering performance, high adaptability and integration, long service life and the like.

Owner:SHAOXING UNIVERSITY

Method for filtering by adoption of full-band variable structure working condition self-adaptive wave filtering, electrification and adsorption

InactiveCN105864184ANo vibrationExtended service lifeServometer circuitsFluid-pressure actuator componentsAdaptive filterFuel tank

The invention relates to a method for filtering by adoption of full-band variable structure working condition self-adaptive wave filtering, electrification and adsorption. According to the method, the pressure / flow pulsation of hydraulic oil is dampened through a filter, and a full-band variable structure working condition self-adaptive wave filter is adopted; solid particle separation is achieved through a U-shaped particle separation module, so that solid particles in an oil liquid move towards a pipe wall, the oil liquid rich in solid particles and near the pipe wall enters an oil return cylinder through an oil return cylinder module and then backflows to an oil tank, the oil liquid containing trace amounts of small-sized particles and existing at the pipe center enters an inner cylinder through an inner cylinder oil inlet pipe for high-precision filtering, and the service life of a filtering core is prolonged, and the wave filtering cost and complexity can be reduced; the oil liquid entering the inner cylinder oil inlet pipe flows into the spiral flow channel of the inner cylinder in a tangential inflow manner, and the inner cylinder wall is taken as the filtering core, so that a filtrate flows while clinging to the filtering core under the action of centrifugal force, that is, the filtrate quickly flows parallel to the surface of the filtering core, and the filtered hydraulic oil outflows into an outer cylinder in the direction perpendicular to the surface of the filtering core; and pollution particles depositing at the bottom of the inner cylinder can be regularly discharged into the oil return cylinder through an electric control check valve, so that the service life of the filtering core can be prolonged.

Owner:李昊

Hydraulic system filter adopting magnetizing, adsorbing and centrifuging

InactiveCN105864173AExtended service lifeIncreasing the thicknessMagnetic separationFluid-pressure actuator componentsTemperature controlEngineering

The invention relates to a filter for a hydraulic system using magnetization, adsorption and centrifugation. A U-shaped particle separation module, an oil return cylinder and an outer barrel are sequentially placed on the bottom plate; the U-shaped particle separation module is provided with a hydraulic oil inlet. It includes a U-shaped tube, on which a temperature control module, a magnetization module, a mechanical centrifuge module, an adsorption module and a degaussing module are installed in sequence; the U-shaped particle separation module and the upper part of the oil return cylinder are connected through an oil return cylinder oil inlet pipe; The inner cylinder is placed in the outer barrel, which is installed on the end cover through a top plate and several bolts; the spiral flow channel is accommodated in the inner cylinder, and is connected with the U-shaped particle separation module through an inner cylinder oil inlet pipe; the inner cylinder inlet The oil pipe is located in the oil inlet pipe of the oil return cylinder and extends into the center of the U-shaped particulate separation module; the filter element is arranged on the inner wall of the inner cylinder; a hydraulic oil outlet is provided at the bottom of the outer barrel. The invention has many advantages such as good filtering performance, high adaptability and integration, long service life and the like.

Owner:SHAOXING UNIVERSITY

Method of filtering oil through full-band filtering, electrification, separation and adsorption

InactiveCN106015184AImprove filtration performanceExtended service lifeMagnetic separationFluid-pressure actuator componentsFull bandCheck valve

The invention relates to a method of filtering oil through full-band filtering, electrification, separation and adsorption. According to the method, the pressure and flow pulsation of hydraulic oil is attenuated by a full-band wave filter; the separation of solid particles is realized by a U-shaped particle separation module, so that the solid particles in oil move toward the wall of a pipe, enter a return oil drum through an air inlet pipe of the return oil drum and then reversely flow to an oil tank, and oil containing trace amount of particles with small particle sizes in the center of a pipeline enters an inner drum through an oil inlet pipe of the inner drum to suffer high-accuracy filtration, thereby prolonging the service life of a filter element; the oil entering the oil inlet pipe of the inner drum flows into a spiral channel of the inner drum in a tangent inflowing manner; the wall of the inner drum serves as a filter element, so that filtrate flows in a manner of clinging to the filter element under the action of centrifugal force, parallels to the surface of the filter element and quickly flow, and the filtered hydraulic oil is vertical to the surface direction of the filter element and outflows to the outer drum; and polluted particles deposited at the bottom of the inner drum can be discharged to the return oil drum timely by an electronic control check valve, thereby prolonging the service life of the filter element.

Owner:王雅莉

Oil tank for treating hydraulic oil through magnetization and electrically controlled ring adsorption

InactiveCN105909571ASimple structureReduce volumePump assembliesServometer circuitsMagnetEngineering

The invention relates to an oil tank for treating hydraulic oil through magnetization and electrically controlled ring adsorption. A filtering box, a permanent magnet, a separation plate and a heater are sequentially arranged in the oil tank. A first oil return pipe is inserted into an oil tank body, and a cooler and a temperature sensor are arranged on the first oil return pipe. One end of a second oil return pipe is connected to the first oil return pipe, and the other end of the second oil return pipe extends into the filtering box. A U-shaped pipe is sequentially provided with a magnetization device and adsorption devices. A downward-inclining debubbling plate is mounted at the top of the filtering box, and a magnetic metal net is laid on the surface of the debubbling plate. An oil sucking pipe is inserted into the oil tank body and provided with an oil filter, a magnetic eraser and a residual magnetism sensor. Homopolar adjacent adsorption rings are adopted by the adsorption devices. The mechanical, electrical and magnetic technologies and the like are combined, solid particles are gathered to the pipe wall to be adsorbed, and air is separated out or ablated; and the oil tank is simple in structure, low in cost and high in oil purifying capacity.

Owner:SHAOXING UNIVERSITY

Filtering method adopting magnetization and adsorption for hydraulic system

InactiveCN105909608AExtended service lifeIncreasing the thicknessMagnetic separationFluid-pressure actuator componentsMagnetizationSolid particle

The invention relates to a filtering method adopting magnetization and adsorption for a hydraulic system. Separation of solid particles is achieved through a U-shaped particle separating module, and the solid particles in oil are made to move to the pipe wall; at an outlet of the U-shaped particle separating module, the oil which is rich in the solid particles and near the pipe wall enters an oil return barrel through an oil return barrel oil inlet pipe and then flows back into an oil tank, and the oil which contains trace of small-diameter particles and is located in the pipe center enters an inner barrel through an inner barrel oil inlet pipe to be subjected to high-precision filtering, so that the service life of a filter element is prolonged, and the filtering cost and complexity are lowered; the oil entering the inner barrel oil inlet pipe flows into a spiral flow channel of the inner barrel in a tangential inflow mode, the inner barrel wall is used as the filter element, filter liquor flows close to the filter element under the effect of centrifugal force, the filter liquor quickly flows in parallel to the surface of the filter element, and the filtered hydraulic oil flows out to an outer barrel in the direction perpendicular to the surface of the filter element; and polluting particles deposited at the bottom of the inner barrel can be regularly discharged to the oil return barrel through an electrically operated check valve, so that the service life of the filter element is prolonged.

Owner:张国云

Method for treating hydraulic oil by adopting magnetization, electric control loop adsorption and rotating magnetic field

InactiveCN105864186AAvoid adsorptionPromote decomposition and ablationPump assembliesFluid-pressure actuator componentsMagnetizationSolid particle

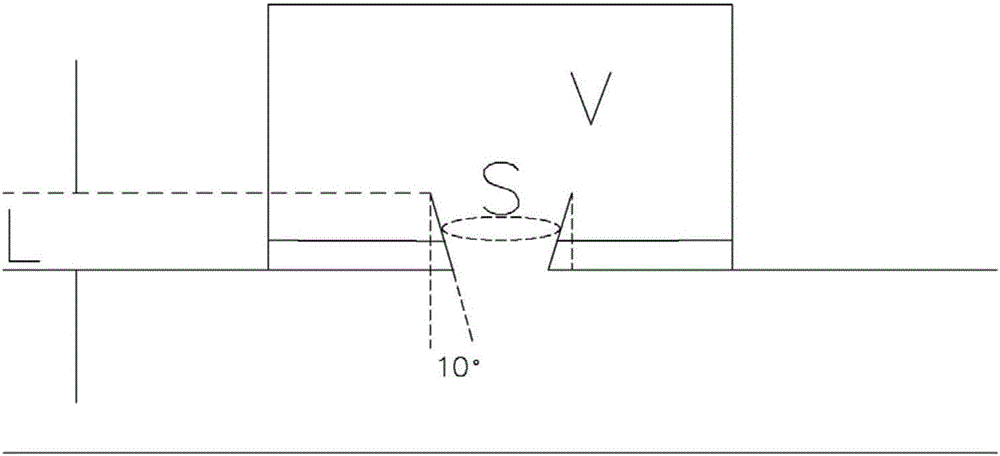

The invention relates to a method for treating hydraulic oil by adopting magnetization, electric control loop adsorption and a rotating magnetic field. During treatment, the hydraulic oil is treated through a first oil return pipe, a magnetization device, a first adsorption device, a rotating magnetic field device, a second adsorption device, a U-shaped pipe, a filtering box, a bubble ablation plate, a permanent magnet, a partition and an oil suction pipe in sequence, so that bubbles dissociating in returned oil can be ablated or separated out and micro-sized particles can be adsorbed or ablated; and both the first and second adsorption devices adopt homopolar adjacent adsorption loops. The method provided by the invention integrates mechanical, electric, magnetic and several other technologies; according to the method, solid particles can be aggregated near a pipe wall for adsorption, and air can be separated out or ablated; and the treatment cost is low, the treatment effect is good, the oil liquid purifying capability is strong, and the possibility of secondary pollution is low.

Owner:SHAOXING UNIVERSITY

Filter adopting variable-structure work condition self-adaptive filtering, electrification and rotating magnetic field

InactiveCN105889224ANo vibrationExtended service lifeFluid-pressure actuator componentsElectricityAdaptive filter

The invention relates to a filter adopting variable-structure work condition self-adaptive filtering, electrification and a rotating magnetic field. A filter, a U-shaped particle separation module, an oil return barrel and an outer barrel of the filter are sequentially arranged on a bottom plate; the filter is connected with the U-shaped particle separation module, and a variable-structure work condition self-adaptive filter is adopted as the filter; the U-shaped particle separation module comprises a U-shaped pipe which is sequentially provided with an electrification module, a separation module, a first adsorption module, a rotating magnetic field centrifugal module, a second adsorption module and a demagnetization module; the U-shaped particle separation module is connected with the upper portion of the oil return barrel through an oil inlet pipe of the oil return barrel; an inner barrel is arranged in the outer barrel and installed on an end cover; a spiral flow channel is contained in the inner barrel and connected with the U-shaped particle separation module through an oil inlet pipe of the inner barrel; the oil inlet pipe of the inner barrel is located in the oil inlet pipe of the oil return barrel; and a filter element is arranged on the inner wall of the inner barrel. The filter adopting variable-structure work condition self-adaptive filtering, electrification and the rotating magnetic field has the multiple beneficial effects of being good in filtering performance, high in adaptability and integration performance, long in service life and the like.

Owner:SHAOXING UNIVERSITY

Method adopting magnetization, centrifugation, adsorption and rotating magnetic field to treat hydraulic oil

InactiveCN105971984AReduce processing costsImprove adsorption capacityFluid-pressure actuator componentsElectricityMagnet

Owner:张华芳

Oil tank for treating hydraulic oil through magnetization, cyclone centrifugation, adsorption and rotating magnetic field

InactiveCN105864117AImprove adsorption capacityAvoid adsorptionPump assembliesServometer circuitsAir filterCentrifugation

The invention relates to an oil tank for treating hydraulic oil through magnetization, cyclone centrifugation, adsorption and a rotating magnetic field. An air filter is arranged on the top of the outside of an oil tank body, and a filtering tank, a permanent magnet, a partition and a heater are sequentially arranged inside the oil tank body; a first oil returning pipe is inserted into the oil tank body, connected with a U-type pipe and provided with a cooler and a temperature sensor; one end of a second oil returning pipe is connected to the first oil returning pipe, and the other end of the second oil returning pipe extends into the filtering tank; the U-type pipe is sequentially provided with a magnetization device, a cyclone centrifugation device, a first adsorption device, a rotating magnetic field device and a second adsorption device; a downwards-inclined defoaming board is installed on the top of the filtering tank; a layer of magnetic metal net is laid on the surface of the defoaming board; and an oil suction pipe is inserted into the oil tank body and provided with an oil filter, a magnetic eraser and a residual magnetism sensor. The mechanical, electrical, magnetic and other technologies are combined, so that solid particles are gathered to the pipe wall to be adsorbed and separate out or melt through air, the structure is simple, the cost is low, and the oil liquid purification capacity is high.

Owner:SHAOXING UNIVERSITY

Oil filtering method achieving filtration, magnetization, adsorption, magnetic field rotation and centrifugation with variable structures

InactiveCN105757059ANo vibrationExtended service lifeFluid-pressure actuator componentsFiltrationMagnetization

The invention relates to an oil filtering method achieving filtration, magnetization, adsorption, magnetic field rotation and centrifugation with variable structures. Pressure / flow pulse of hydraulic oil is dampened through a filter, and the filter is a variable-structure filter; separation of solid particles is achieved through a U-shaped particle separation module, solid particles in oil fluid are made to move towards a pipe wall, enter an oil return cylinder through an oil return cylinder inlet pipe, and then flow back to an oil tank, oil fluid containing a small number of small-size particles at the center of a pipeline enters an inner cylinder through an inner cylinder oil inlet pipe for high-precision filtration, and the service life of a filter element is prolonged; oil fluid entering the inner cylinder oil inlet pipe flows into a spiral runner of the inner cylinder in a tangential inflow mode, the filter element is arranged on the wall of the inner cylinder, filtrate flows by being attached to the filter element under the action of centrifugal force and flows fast parallel to the surface of the filter element, and filtered hydraulic oil flows out of an outer cylinder in the direction perpendicular to the surface of the filter element; contamination particles precipitated at the bottom of the inner cylinder can be discharged out of the oil return cylinder periodically through an electric control check valve, and the service life of the filter element is prolonged.

Owner:陈连萍

Method for treating hydraulic oil through magnetization, electric shock hammer adsorption and rotating magnetic field

InactiveCN105864121AAvoid adsorptionPromote decomposition and ablationPump assembliesServometer circuitsTherapeutic effectSolid particle

The invention relates to a method for treating hydraulic oil through magnetization, electric shock hammer adsorption and a rotating magnetic field. During treatment, the hydraulic oil sequentially passes through a first oil return pipe, a magnetization device, a first adsorption device, a rotating magnetic field device, a second adsorption device, a U-shaped pipe, a filter box, a debubbling plate, a permanent magnet, a separating plate and an oil sucking pipe to be treated, and therefore free bubbles in return oil are ablated or separated out, and micron particles are adsorbed or ablated. Same-pole-adjacent type adsorption rings with electric shock hammers are adopted both by the first adsorption device and the second adsorption device. According to the method, mechanical, electrical and magnetic technologies and the like are combined, solid particles are gathered and adsorbed to the pipe wall, and air is separated out or ablated; the treatment cost is low, the treatment effect is good, the oil purifying capacity is high, and secondary pollution is not prone to be caused.

Owner:SHAOXING UNIVERSITY

Oil filtering method adopting full-frequency-band filtering, magnetization, adsorption, rotary magnetic field and centrifuging

InactiveCN105736523ANo vibrationExtended service lifeFluid-pressure actuator componentsMagnetizationFuel tank

The invention relates to an oil filtering method adopting full-frequency-band filtering, magnetization, adsorption, a rotary magnetic field and centrifuging. Pressure / flow pulse of hydraulic oil is attenuated through a filter, and a full-frequency-band filter is adopted; solid particles are separated through a U-shaped particle separation module, so that the solid particles in oil liquid move towards a pipe wall, enter an oil returning barrel from an oil feeding pipe of the oil returning barrel and then reflow back an oil tank; the oil liquid at the center of the pipeline containing small-grain-diameter particles enters an inner barrel through the oil feeding pipe of the inner barrel to be subjected to high-precision filtering, so that the service life of a filter element is prolonged; the oil liquid entering the oil feeding pipe of the inner barrel flows into a spiral flow channel of the inner barrel in a tangential liquid entering manner; an inner barrel wall is the filter element and filtrate flows under the action of a centrifugal force in a manner of being close to the filter element; the filtrate flows rapidly in a direction parallel to the surface of the filter element, and the filtered hydraulic oil flows out to an outer barrel in a direction vertical to the surface of the filter element; and polluted particles deposited at the bottom of the inner barrel can be discharged out to the oil returning barrel through an electric control check valve regularly so that the service life of the filter element is prolonged.

Owner:徐燚超

Filter tank adopting work-condition-adaptive filtering, magnetization, rotary magnetic field and centrifugation

InactiveCN105864200AImprove filtration performanceExtended service lifeFluid-pressure actuator componentsAdaptive filterSelf adaptive

The invention relates to a filter box with working condition adaptive filtering, magnetization, rotating magnetic field and centrifugal. The filter, U-shaped particle separation module, oil return cylinder and outer barrel are placed on the bottom plate in sequence; the filter and U-shaped particle The separation module is connected, which adopts a working condition adaptive filter; the U-shaped particle separation module includes a U-shaped tube, and the U-shaped tube is sequentially installed with a temperature control module, a magnetization module, a mechanical centrifuge module, a first adsorption module, and a rotating magnetic field centrifuge. module, the second adsorption module and the degaussing module; the U-shaped particle separation module and the upper part of the oil return cylinder are connected through the oil return pipe of the oil return cylinder; the inner cylinder is placed in the outer barrel, which is installed on the end cover; the spiral flow channel is contained in the In the barrel, it is connected with the U-shaped particle separation module through the oil inlet pipe of the inner barrel; the oil inlet pipe of the inner barrel is located in the oil inlet pipe of the oil return barrel; the filter element is arranged on the inner wall of the inner barrel. The invention has many advantages such as good filtering performance, high adaptability and integration, long service life and the like.

Owner:谢阿招

Filter device adopting filter, magnetization, absorption and magnetic field rotation

InactiveCN105952717ANo vibrationExtended service lifeMagnetic separationFluid-pressure actuator componentsTemperature controlMagnetization

The invention relates to a filtering device adopting filter, magnetization, adsorption and rotating magnetic field. The filter, U-shaped particle separation module, oil return cylinder and outer bucket are sequentially placed on the bottom plate; the filter is connected with the U-shaped particle separation module , which uses a full-band hydraulic system pressure pulsation filter; the U-shaped particle separation module includes a U-shaped tube, and the U-shaped tube is sequentially installed with a temperature control module, a magnetization module, a first adsorption module, a rotating magnetic field centrifugal module, and a second adsorption module and degaussing module; the U-shaped particle separation module and the upper part of the oil return cylinder are connected through the oil return pipe of the oil return cylinder; the inner cylinder is placed in the outer barrel, which is installed on the end cover; The U-shaped particle separation modules are connected through the oil inlet pipe of the inner cylinder; the oil inlet pipe of the inner cylinder is located in the oil inlet pipe of the oil return cylinder; the filter element is arranged on the inner wall of the inner cylinder. The invention has many advantages such as good filtering performance, high adaptability and integration, long service life and the like.

Owner:SHAOXING UNIVERSITY

Oil filtering device using variable structure filtering, electrifying, separating, centrifuging and rotating magnetic filed

InactiveCN105971994ANo vibrationExtended service lifeFluid-pressure actuator componentsElectricityParticulates

The invention relates to an oil filter device using variable structure filtering, electrification, separation, centrifugation and rotating magnetic field. The filter, U-shaped particle separation module, oil return cylinder and outer barrel are sequentially placed on the bottom plate; the filter and U The U-shaped particle separation module is connected with a variable structure filter; the U-shaped particle separation module includes a U-shaped tube, and the U-shaped tube is sequentially installed with an electrification module, a separation module, a first adsorption module, a mechanical centrifugal module, and a second adsorption module. module and degaussing module; the U-shaped particle separation module and the upper part of the oil return cylinder are connected through the oil return pipe of the oil return cylinder; the inner cylinder is placed in the outer barrel, which is installed on the end cover; The U-shaped particle separation modules are connected through the oil inlet pipe of the inner cylinder; the oil inlet pipe of the inner cylinder is located in the oil inlet pipe of the oil return cylinder; the filter element is arranged on the inner wall of the inner cylinder. The invention has many advantages such as good filtering performance, high adaptability and integration, long service life and the like.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Oil filtering device adopting working-condition self-adaptive filtering, electrification, separation and adsorption

InactiveCN105864217ANo vibrationExtended service lifeFluid-pressure actuator componentsElectricitySelf adaptive

The invention relates to an oil filter device with self-adaptive filtering, electrification, separation and adsorption of working conditions. The filter, U-shaped particle separation module, oil return cylinder and outer barrel are sequentially placed on the bottom plate; the filter and U-shaped The particle separation module is connected; the U-shaped particle separation module includes a U-shaped tube, and the U-shaped tube is sequentially installed with an electrification module, a separation module, an adsorption module and a degaussing module; the U-shaped particle separation module and the oil return cylinder pass through a loop The oil inlet pipe of the oil barrel is connected; the inner barrel is placed in the outer barrel, which is installed on the end cover through a top plate and several bolts; the spiral flow channel is accommodated in the inner barrel, and the U-shaped particle separation module is passed through an inner barrel. The oil pipe is connected; the oil inlet pipe of the inner cylinder is located in the oil inlet pipe of the oil return cylinder, and extends into the center of the U-shaped particle separation module; the filter element is arranged on the inner wall of the inner cylinder. The invention has many advantages such as good filtering performance, high adaptability and integration, long service life and the like.

Owner:SHAOXING UNIVERSITY

Oil filtering system adopting full-band filtering, electrifying, separating, adsorbing and centrifuging

InactiveCN105889215ANo vibrationExtended service lifeFluid-pressure actuator componentsFull bandParticle separation

The invention relates to an oil filtering system adopting full-band filtering, electrifying, separating, adsorbing and centrifuging. A filter, a U-shaped particle separation module, an oil returning barrel and an outer barrel of the oil filtering system are sequentially arranged on a bottom plate. The filter is connected with the U-shaped particle separation module, and a full-band filter is adopted as the filter. The U-shaped particle separation module comprises a U-shaped pipe. An electrification module, a separation module, a first adsorption module, a mechanical centrifuge module, a second adsorption module and a demagnetization module are sequentially arranged on the U-shaped pipe. The upper portion of the U-shaped particle separation module and the upper portion of the oil returning barrel are connected through an oil returning barrel oil inlet pipe. An inner barrel is arranged in the outer barrel and installed on an end cover. A spiral runner is contained in the inner barrel and connected with the U-shaped particle separation module through an inner barrel oil inlet pipe. The inner barrel oil inlet pipe is located in the oil returning barrel oil inlet pipe. A filter element is arranged on the inner wall of the inner barrel. The oil filtering system has the multiple beneficial effects that the filtering performance is good, adaptability and integrity are high, and the service life is long.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Oil filtering method adopting full-band work condition self-adaptive filtering, adsorption and rotating magnetic field

InactiveCN105864176ANo vibrationExtended service lifeMagnetic separationFluid-pressure actuator componentsAdaptive filterFuel tank

The invention relates to an oil filtering method using self-adaptive filtering, adsorption and rotating magnetic field in full-frequency band working conditions, which attenuates the pressure / flow pulsation of hydraulic oil through the filter, and adopts full-band working condition self-adaptive filter; through U-shaped The particle separation module realizes the separation of solid particles, so that the solid particles in the oil move to the pipe wall, and enter the oil return cylinder through the oil return tube inlet pipe and then return to the oil tank. The oil in the center of the pipeline containing trace small particles passes through The oil inlet pipe of the inner cylinder enters the inner cylinder for high-precision filtration, which prolongs the service life of the filter element; Under the action of centrifugal force, it flows close to the filter element, the filtrate flows quickly parallel to the surface of the filter element, and the filtered hydraulic oil flows out to the outer cylinder perpendicular to the surface of the filter element; the pollution particles deposited at the bottom of the inner cylinder can pass through the electronically controlled check valve at regular intervals It is discharged to the oil return cylinder, thereby increasing the service life of the filter element.

Owner:王雅莉

Oil filtering device achieving full-band-working-condition self-adapted filtering, magnetization, adsorption and centrifugation

InactiveCN106402093ANo vibrationExtended service lifeFluid-pressure actuator componentsTemperature controlAdaptive filter

The invention relates to an oil filtering device achieving full-band-working-condition self-adapted filtering, magnetization, adsorption and centrifugation. According to the oil filtering device achieving full-band-working-condition self-adapted filtering, magnetization, adsorption and centrifugation, a filter, a U-shaped particle separation module, an oil return barrel and an external barrel are sequentially arranged on a base plate; the filter is connected with the U-shaped particle separation module, and the full-band-working-condition self-adapted filter is adopted; the U-shaped particle separation module comprises a U-shaped pipe, and a temperature control module, a magnetization module, a mechanical centrifugation module, an adsorption module and a demagnetization module are sequentially installed on the U-shaped pipe; the U-shaped particle separation module is connected with the upper portion of the oil return barrel through an oil return barrel oil inlet pipe; an inner barrel is arranged inside the outer barrel and installed on an end cover; a spiral flow channel is contained in the inner barrel and connected with the U-shaped particle separation module through an inner barrel oil inlet pipe; the inner barrel oil inlet pipe is located inside the oil return barrel oil inlet pipe and extends into the center of the U-shaped particle separation module; and a filter element is arranged on the inner wall of the inner barrel. The oil filtering device achieving full-band-working-condition self-adapted filtering, magnetization, adsorption and centrifugation has the advantages of being good in filtering performance and adaptability, high in integration, long in service life and the like.

Owner:谢阿招

Oil filtering method adopting filter, magnetization and adsorption

InactiveCN105889184ANo vibrationExtended service lifeFluid-pressure actuator componentsMagnetizationSystem pressure

The invention relates to an oil filtering method adopting a filter, magnetization and adsorption. Pressure and flow pulsation of hydraulic oil is attenuated by means of the filter, and a full-frequency-band hydraulic system pressure pulsation filter is adopted as the filter; separation of solid particles can be achieved by means of a U-type particle separation module, so that the solid particles in oil move to a pipe wall, the solid particles flow back to an oil tank after entering an oil return cylinder through an oil return cylinder oil inlet pipe, oil in the center of a pipeline containing a small quantity of small-grain-size particles enters an inner cylinder through an inner cylinder oil inlet pipe for high-precision filtering, and the service life of a filter element is prolonged; the oil entering the inner cylinder oil inlet pipe flows into a spiral channel of the inner cylinder in a tangential inflow mode, an inner cylinder wall serves as the filter element, filter liquid is attached to the filter element to flow under the action of centrifugal force, the filter liquid quickly flows parallel to the surface of the filter element, and the filtered hydraulic oil flows out of an outer cylinder in the direction perpendicular to the surface of the filter element; pollution particles deposited at the bottom of the inner cylinder are discharged out of the oil return cylinder through an electric control check valve, and accordingly the service life of the filter element is prolonged.

Owner:SHAOXING UNIVERSITY

Oil filtering method adopting full-frequency-band working condition self-adaptive filtering, magnetization, rotary magnetic field and centrifuging

InactiveCN105736524ANo vibrationExtended service lifeFluid-pressure actuator componentsAdaptive filterMagnetization

The present invention relates to an oil filtering method using self-adaptive filtering, magnetization, magnetic field and centrifugation in full frequency band working conditions, which attenuates the pressure / flow pulsation of hydraulic oil through the filter, and adopts full frequency band working condition self-adaptive filter; through U The type particle separation module realizes the separation of solid particles, so that the solid particles in the oil move to the pipe wall, and enter the oil return cylinder through the oil return tube inlet pipe and then return to the oil tank. The oil in the center of the pipeline containing a small amount of small particles Enter the inner cylinder through the oil inlet pipe of the inner cylinder for high-precision filtration, which improves the service life of the filter element; Under the action of centrifugal force, it flows close to the filter element, the filtrate flows quickly parallel to the surface of the filter element, and the filtered hydraulic oil flows out to the outer cylinder perpendicular to the surface of the filter element; the pollution particles deposited at the bottom of the inner cylinder can be discharged through the electronically controlled check valve at regular intervals to the oil return cylinder to increase the service life of the filter element.

Owner:徐燚超

Oil filter adopting full-band variable-structure work condition self-adaptive filtering, magnetization and adsorption

InactiveCN105864180AImprove filtration performanceExtended service lifeFluid-pressure actuator componentsAdaptive filterSelf adaptive

The invention relates to an oil filter which adopts self-adaptive filtering, magnetization and adsorption under full-frequency variable structure working conditions. The structural condition adaptive filter is connected with the U-shaped particle separation module; the U-shaped particle separation module includes a U-shaped tube, and the U-shaped tube is equipped with a temperature control module, a magnetization module, an adsorption module and a degaussing module; the U-shaped particle separation module The separation module and the oil return cylinder are connected through the oil inlet pipe of the oil return cylinder; the inner cylinder is placed in the outer barrel, which is installed on the end cover; the spiral flow channel is accommodated in the inner cylinder, and it and the U-shaped particle separation module enter through an inner cylinder. The oil pipe is connected; the oil inlet pipe of the inner barrel is located in the oil inlet pipe of the oil return barrel and extends into the center of the U-shaped particle separation module; the filter element is arranged on the inner wall of the inner barrel; a hydraulic oil outlet is provided at the bottom of the outer barrel. The invention has many advantages such as good filtering performance, high adaptability and integration, long service life and the like.

Owner:SHAOXING UNIVERSITY

Filtering box adopting full-band variable-structure filtering, electrification, adsorption and rotating magnetic field

InactiveCN105864177ANo vibrationExtended service lifeFluid-pressure actuator componentsElectricityFull band

The invention relates to a filter box with full-frequency variable structure filtering, electrification, adsorption and rotating magnetic field. The filter, U-shaped particle separation module, oil return cylinder and outer barrel are sequentially placed on the bottom plate; the filter and U-shaped The particle separation module is connected, which adopts a full-band variable structure filter; the U-shaped particle separation module includes a U-shaped tube, and the U-shaped tube is sequentially installed with an electrification module, a separation module, a first adsorption module, a rotating magnetic field centrifugal module, and a second 2. Adsorption module and degaussing module; the U-shaped particle separation module and the upper part of the oil return cylinder are connected through the oil return pipe of the oil return cylinder; the inner cylinder is placed in the outer barrel, which is installed on the end cover; the spiral flow channel is accommodated in the inner cylinder, It is connected with the U-shaped particle separation module through the oil inlet pipe of the inner cylinder; the oil inlet pipe of the inner cylinder is located in the oil inlet pipe of the oil return cylinder; the filter element is arranged on the inner wall of the inner cylinder. The invention has many advantages such as good filtering performance, high adaptability and integration, long service life and the like.

Owner:SHAOXING UNIVERSITY

Oil filtering device adopting variable structure filtration, electrification, separation, adsorption and rotation magnetic field

InactiveCN105864172ANo vibrationExtended service lifeFluid-pressure actuator componentsElectricityFiltration

The invention relates to an oil filtering device using variable structure filtering, electrification, separation, adsorption and rotating magnetic field. The filter, U-shaped particle separation module, oil return cylinder and outer barrel are placed on the bottom plate in sequence; the filter and U The U-shaped particle separation module is connected with a variable structure filter; the U-shaped particle separation module includes a U-shaped tube, and the U-shaped tube is sequentially installed with an electrification module, a separation module, a first adsorption module, a rotating magnetic field centrifugal module, and a second The adsorption module and the degaussing module; the U-shaped particle separation module and the upper part of the oil return cylinder are connected through the oil return pipe of the oil return cylinder; the inner cylinder is placed in the outer barrel, which is installed on the end cover; It is connected with the U-shaped particle separation module through the oil inlet pipe of the inner cylinder; the oil inlet pipe of the inner cylinder is located in the oil inlet pipe of the oil return cylinder, and extends into the center of the U-shaped particle separation module; the filter element is arranged on the inner wall of the inner cylinder. The invention has many advantages such as good filtering performance, high adaptability and integration, long service life and the like.

Owner:SHAOXING UNIVERSITY

Oil filtering method based on full-band filtration, electrification, separation and centrifugation

InactiveCN105889211ANo vibrationExtended service lifeFluid-pressure actuator componentsFiltrationFuel tank

The invention provides an oil filtering method based on full-band filtration, electrification, separation and centrifugation. According to the oil filtering method, the pressure / flow pulsation of hydraulic oil is attenuated through a filter, and a full-band filter is adopted to serve as the filter; separation of solid particles is achieved through a U-shaped particle separation module, so that the solid particles in the oil are made to flow towards the pipe wall, enter an oil returning cylinder through an oil inlet pipe of the oil returning cylinder and then flow back into an oil tank; the oil, containing a micro amount of particles with small particle sizes, in the center of a pipeline enters an inner cylinder through an oil inlet pipe of the inner cylinder so as to be subjected to high-precision filtration, and thus the service life of a filter element is prolonged; the oil entering the oil inlet pipe of the inner cylinder flows into a spiral passageway of the inner cylinder in a tangential flowing mode, the inner cylinder wall serves as the filter element, filtrate flows closely along the filter element under the action of centrifugal force and flows rapidly in the direction parallel to the surface of the filter element, and the filtered hydraulic oil flows out into an outer cylinder in the direction perpendicular to the surface of the filter element; and contamination particles deposited at the bottom of the inner cylinder can be discharged out into the oil returning cylinder through an electric-control stop valve at regular times, and thus the service life of the filter element is prolonged.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com