Non-quill roller cross universal joint cross trunnion

A cross-axis universal and needle-free technology, which is applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problems of large diameter of cross-axis universal joints, affecting structural strength, and failure of universal joints. To achieve the effect of compact structure, convenient manufacture and lower hardness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

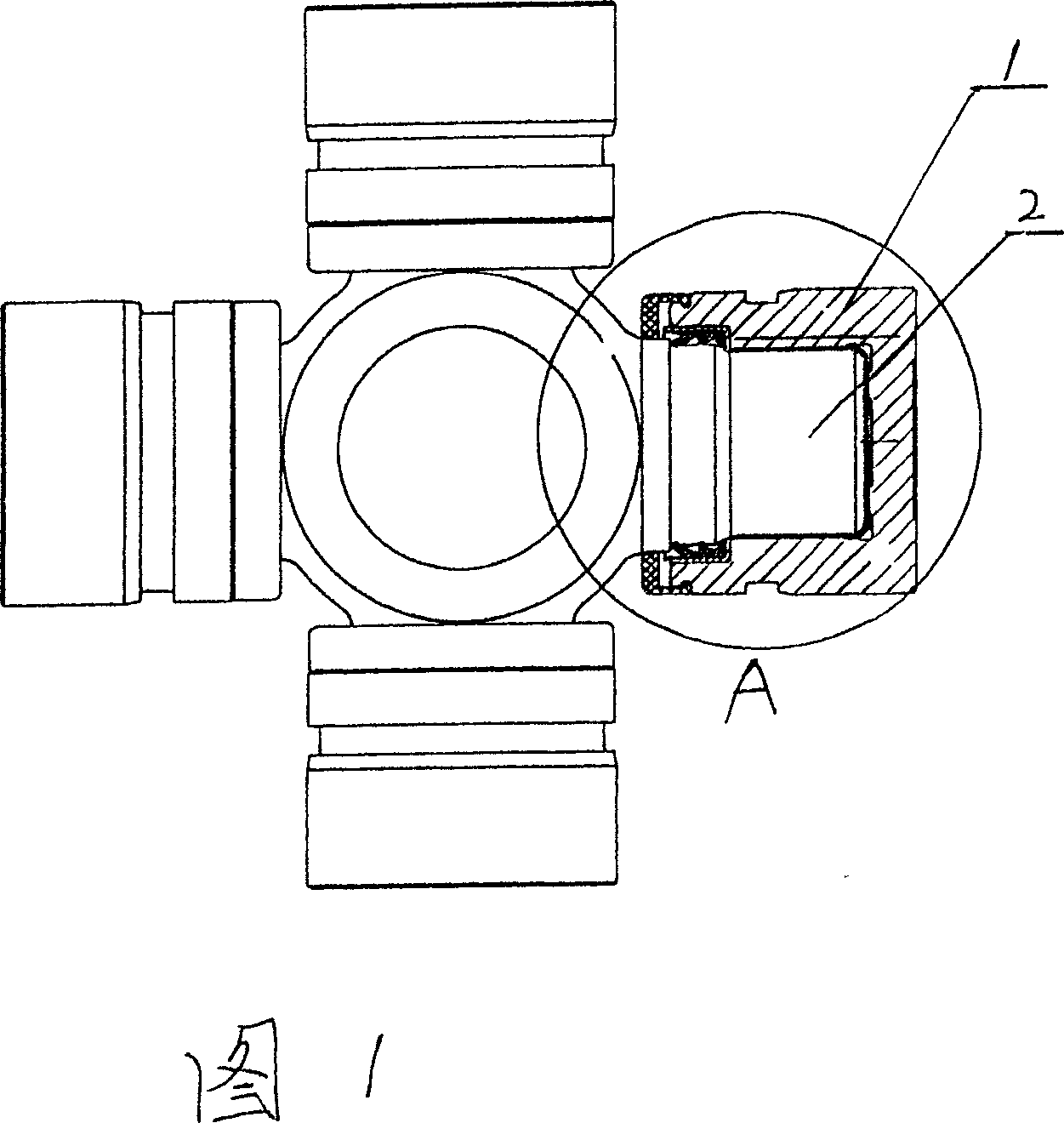

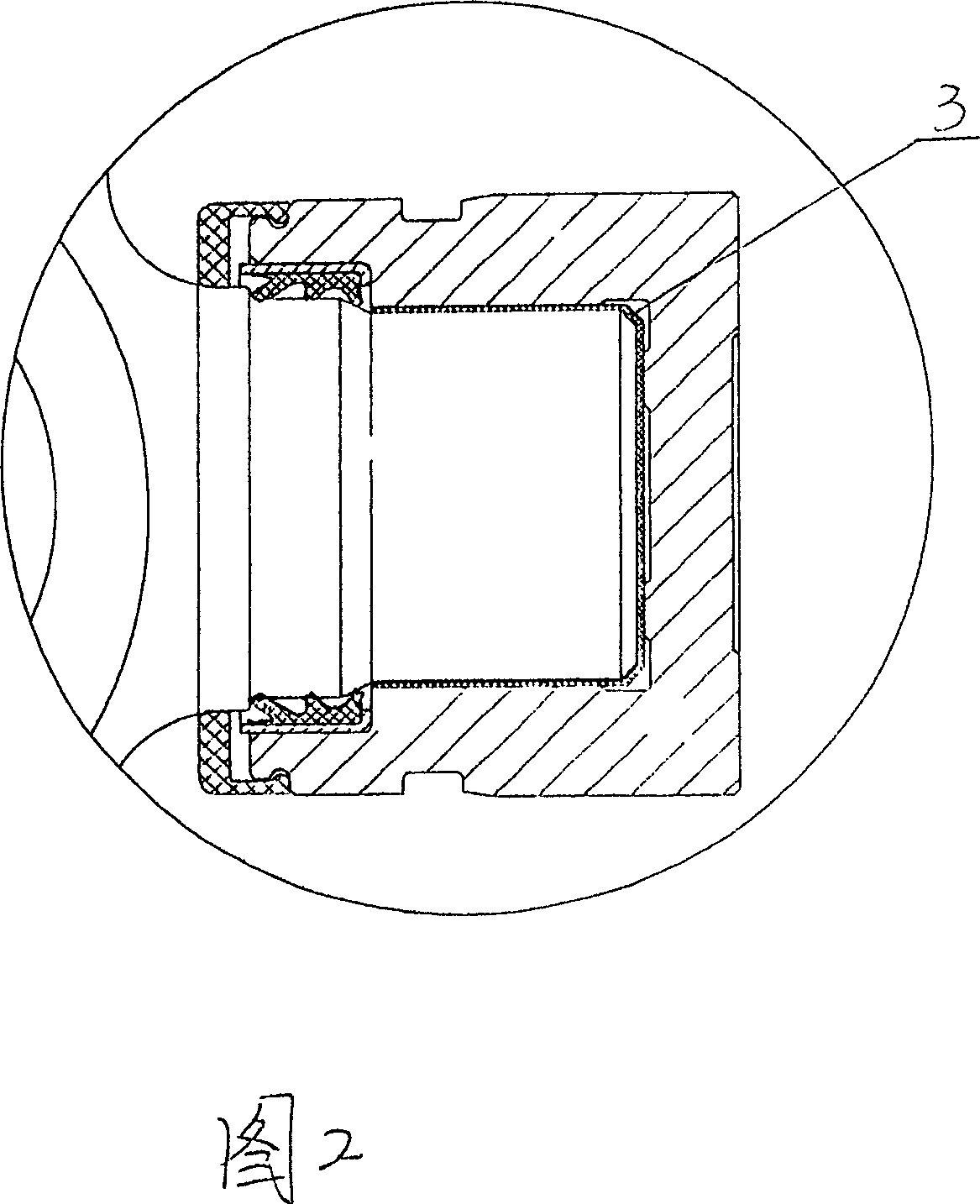

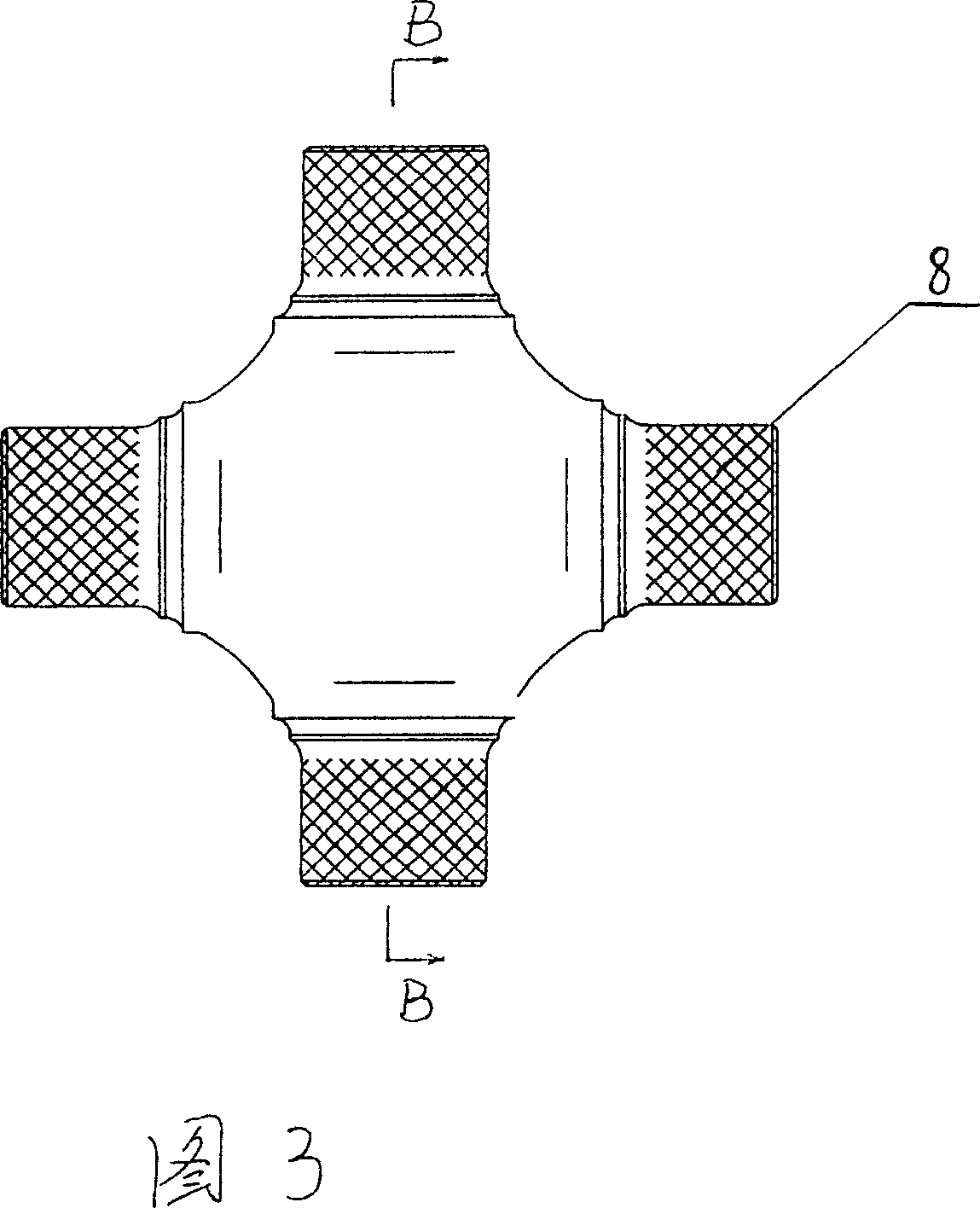

[0022] A needle-free cross shaft universal joint, as shown in Figure 1, includes a cross shaft and a casing 1, the casing 1 is arranged on the head of the cross shaft, and an oil seal is arranged at the end of the casing 1. A cylindrical cup-shaped soft wear-resistant layer 3 is arranged between the casing 1 and the shaft head 2 . The soft wear-resistant layer 3 is homogeneous and roughly equal in thickness. It is formed by coating the outer circumference and end face of the cross shaft with nylon material, and a chamfer is provided between the outer circumference and the end face that is close to the chamfer. The connected soft wear-resistant layer 3. Between the inner wall surface 4 and the bottom surface 5 of the jacket 1, an annular overrun groove 6 is obliquely provided, and the soft wear-resistant layer 3 is evenly coated on the inner wall surface 4, the bottom surface 5 and the overrun groove therebetween. on slot 6. The average wall thickness of the soft wear-resista...

Embodiment 2

[0024] The soft wear-resistant layer 3 described in this embodiment is homogeneous and roughly equal in thickness, and is formed by coating the inner wall and bottom surface of the cross shaft casing 1 with nylon material. The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com