Semi-continuous casting method for light alloy and dedicated apparatus for implementing the same

A semi-continuous casting and light alloy technology, which is applied in the field of light alloy semi-continuous casting and casting methods and special devices for implementing the method, can solve the problem that light alloys and alloy ingots are difficult to produce qualified products, the crystallization temperature gradient is large, and the crystallization temperature is large. Wide temperature range and other problems, to achieve the effect of reducing the uneven crystallization range of the alloy, grain refinement, and fast thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

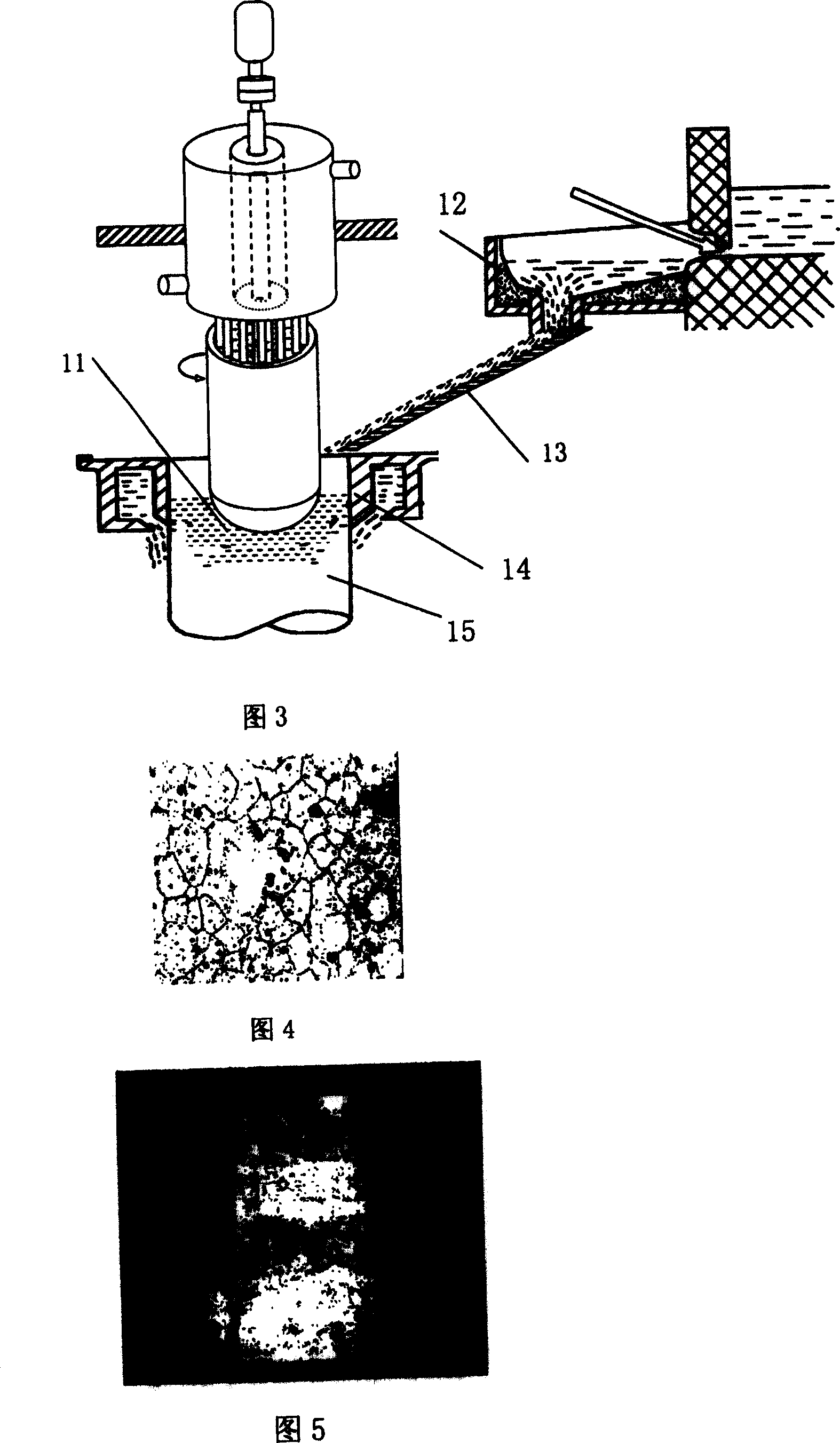

[0021] The semi-continuous method of the light alloy of the present invention still uses a vertical semi-continuous casting machine (see Figure 3). The alloy liquid in the molten pool 12 is transferred to the mold 14 through the launder 13 to form a liquid cavity, and the liquid cavity 11 The heat of the alloy casting liquid is quickly discharged out through the inorganic heat pipe, and the high thermal conductivity and constant temperature controllability of the inorganic heat pipe are used to control the temperature field of the liquid cavity, so that the cooling during crystallization is carried out from the middle to the periphery, and the heat flow direction is just right. Contrary to the traditional, it is very beneficial to the exhaust during solidification, thereby changing the temperature field, greatly reducing the crystallization temperature gradient, which can effectively eliminate casting defects.

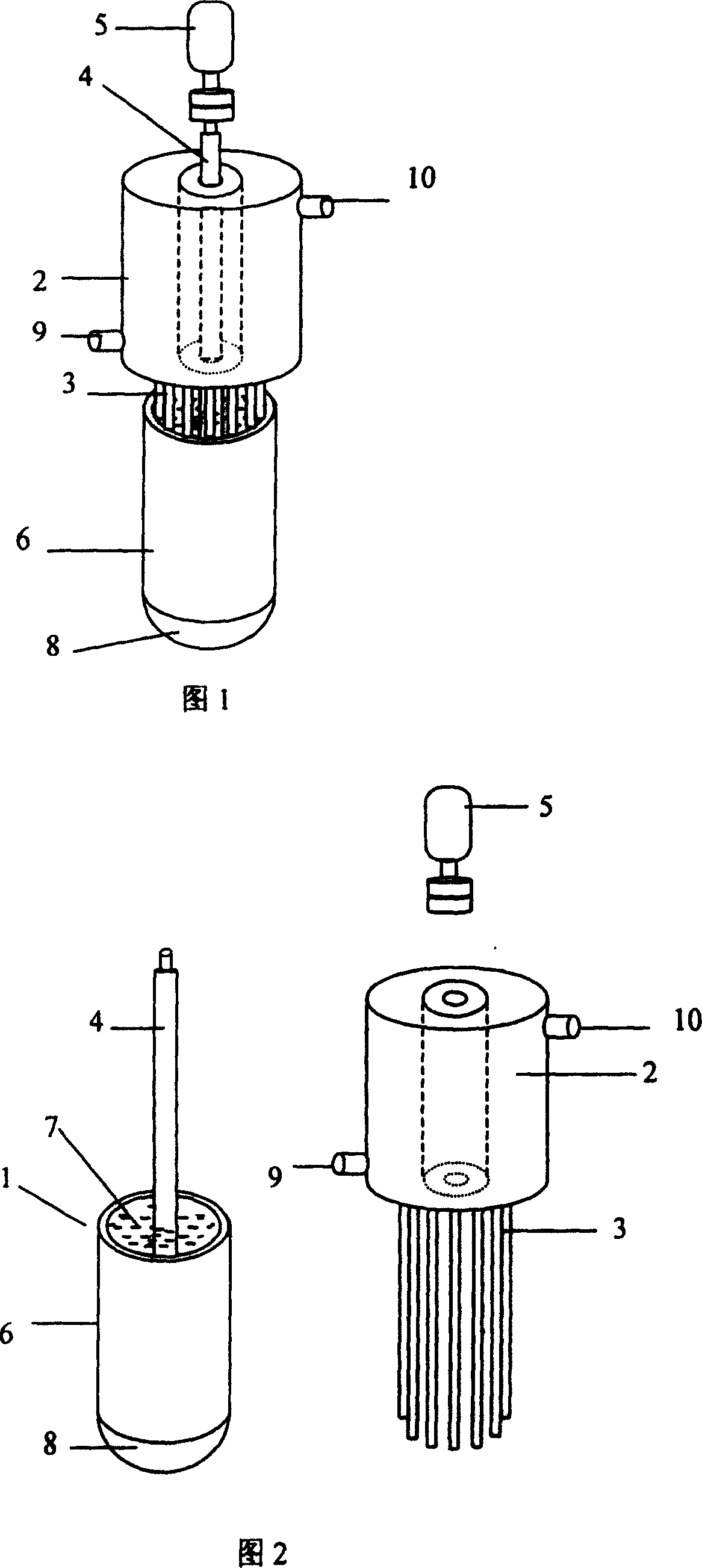

[0022] The structure of the dedicated device for implementing the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com