Sand/dust blowing environmental test equipment system

A technology of environmental test device and circulation device, which is applied in the direction of measuring device, aerodynamic test, machine/structural component test, etc., can solve the problem of sand and dust concentration, particle velocity and uniformity, sand and dust particle velocity and concentration The distribution is not easy to control, the pressure head of the main fan and the energy loss of the system increase, etc., to improve the dust concentration and speed distribution, improve the temperature control effect, and reduce the material and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings.

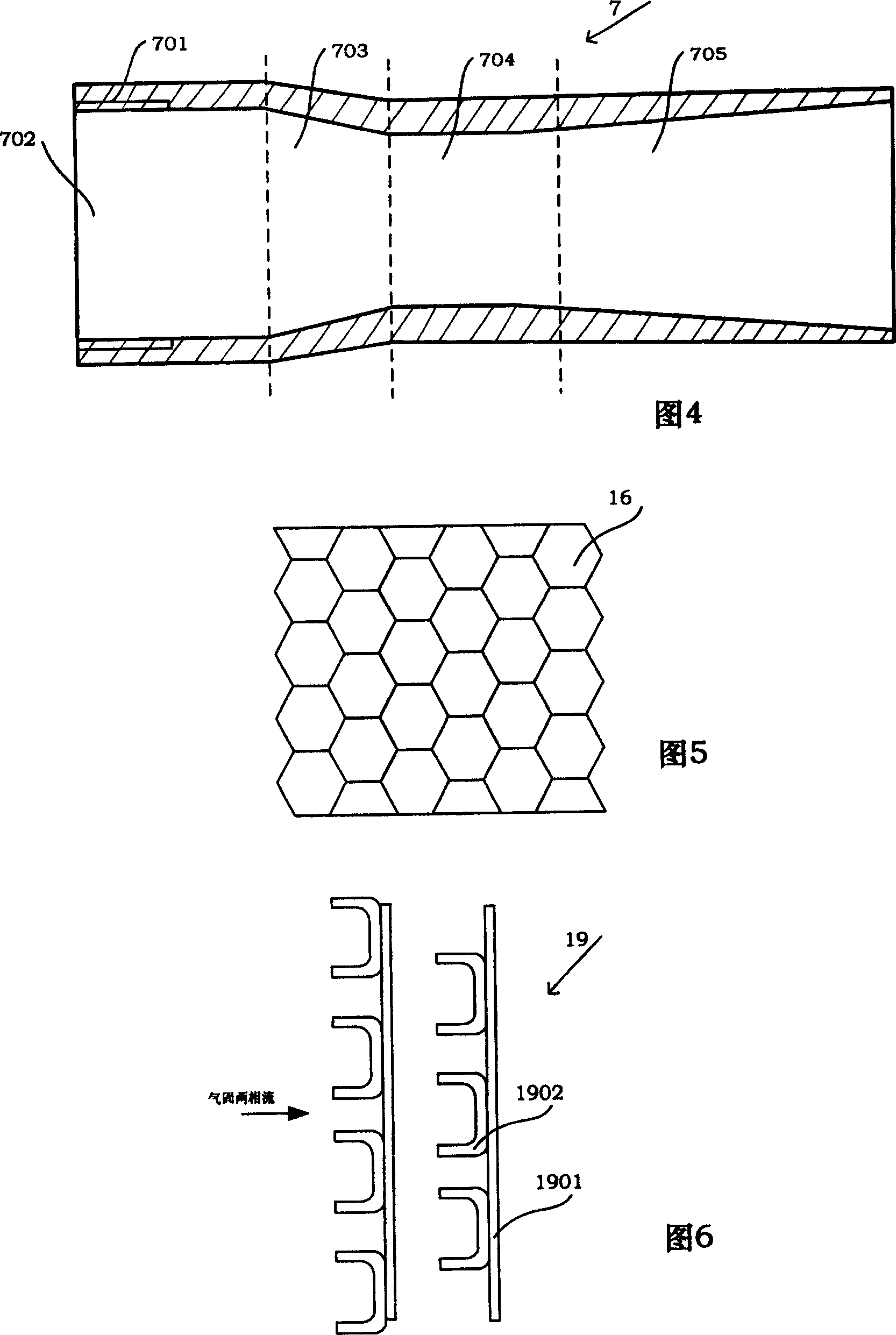

[0015] For sand blowing and dust blowing environment test equipment, it generally includes a sand and dust material system, a circulating air duct, and an air conditioning system. The required sand and dust raw materials; the air conditioning system is used to achieve the temperature and humidity of the test environment. The sand and dust material system and the air conditioning system are connected to the circulating air duct through pipelines. There are multiple valves on each pipeline. Humidity adjustment, humidity adjustment, etc.

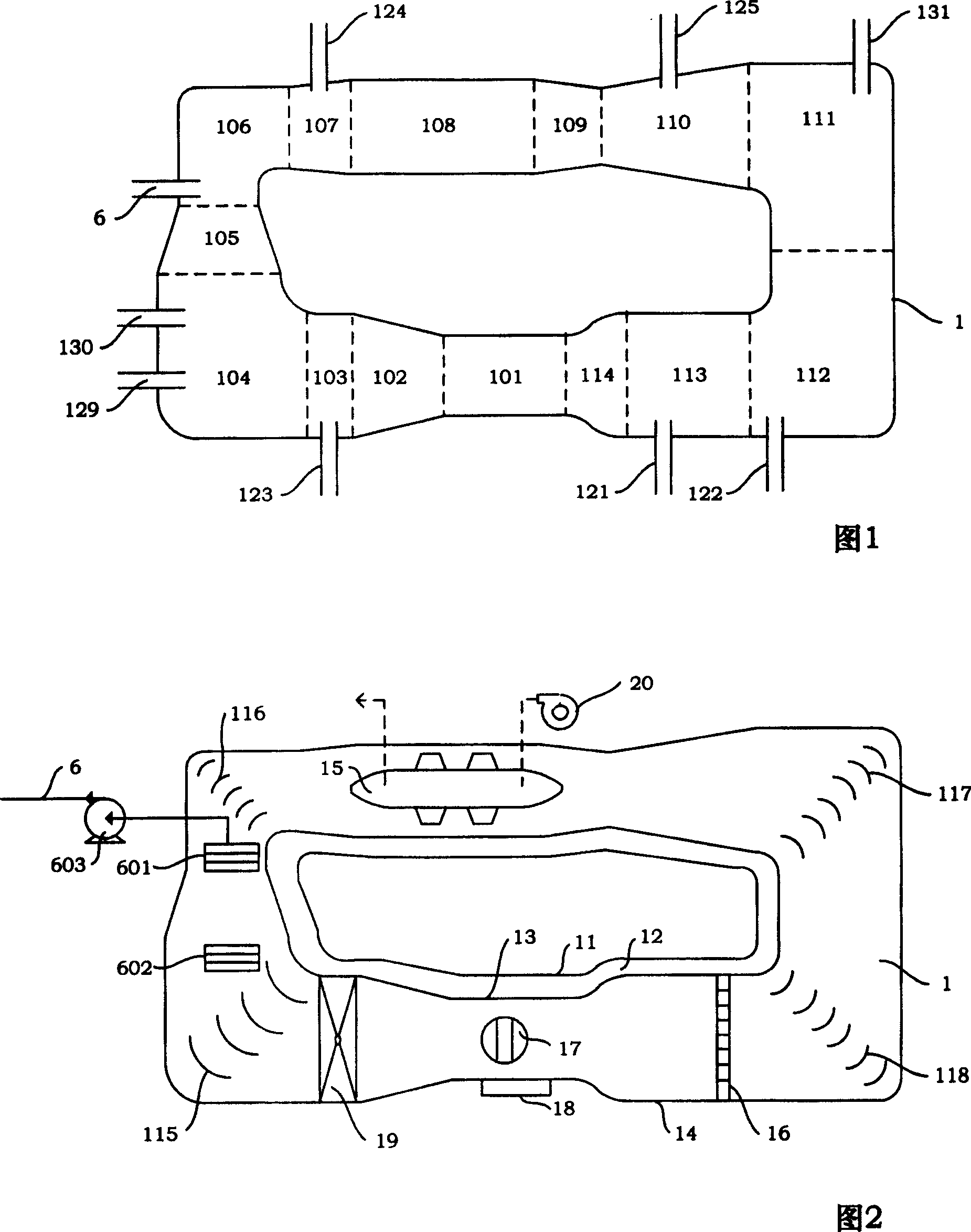

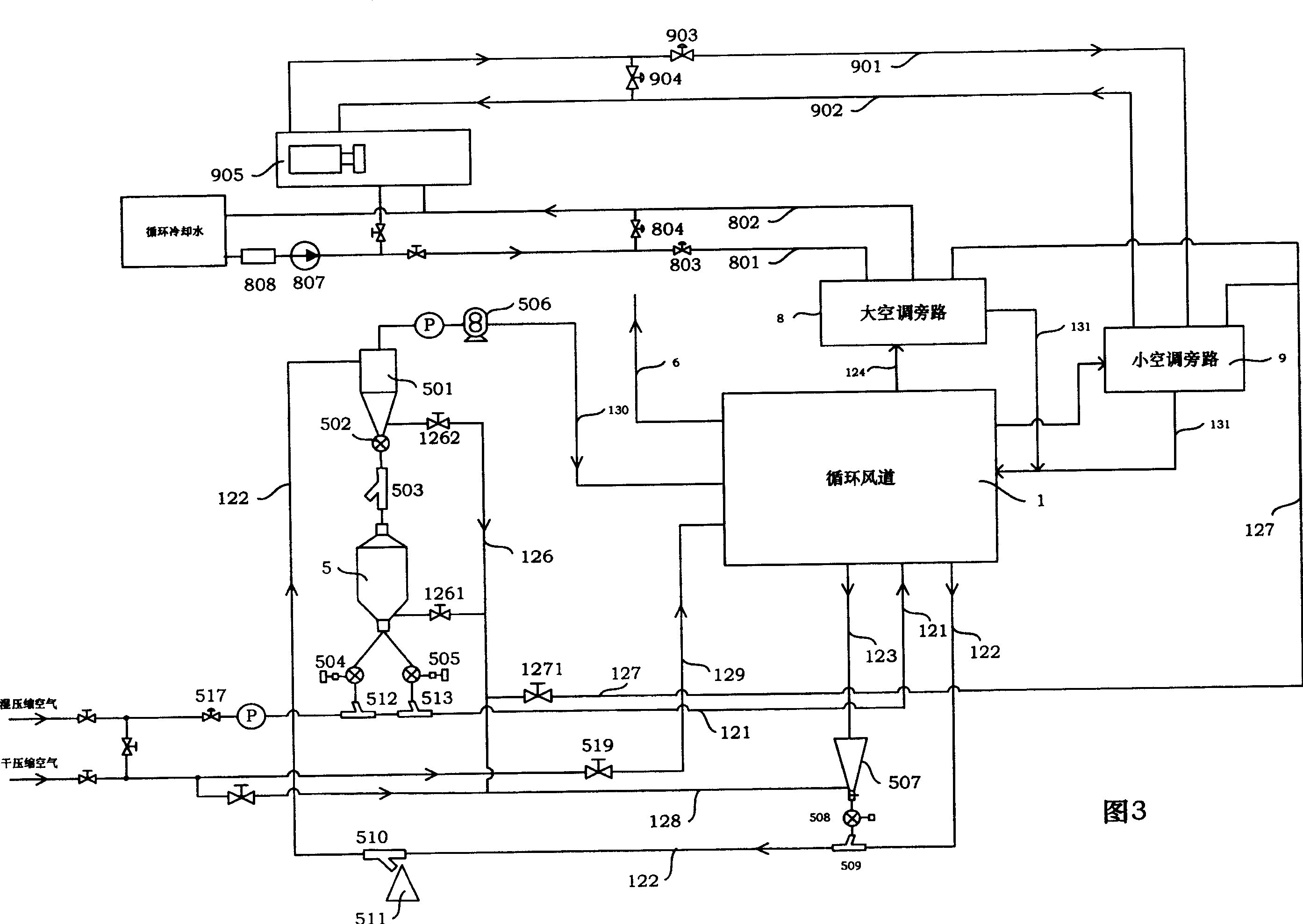

[0016] In the present invention, in order to realize gas-solid two-phase flow, structural improvements are made to the circulating air duct 1 . Circulating air duct 1 is a closed air duct with irregular structure. Circulating air duct 1 is divided into test section 101, diffuser section 102, separation section 103, first cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com