Dynamic micro filter membrane assembly and water treatment process method

A technology of microfiltration membrane and dynamic membrane, applied in the field of dynamic microfiltration membrane module and water treatment process, can solve the problems of high production cost, difficult to realize online cleaning, small volume ratio, etc., achieve simple structure, increase membrane filtration area, The effect of increasing the withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will now be further described in conjunction with the accompanying drawings and embodiments, but not as a limitation of the present invention.

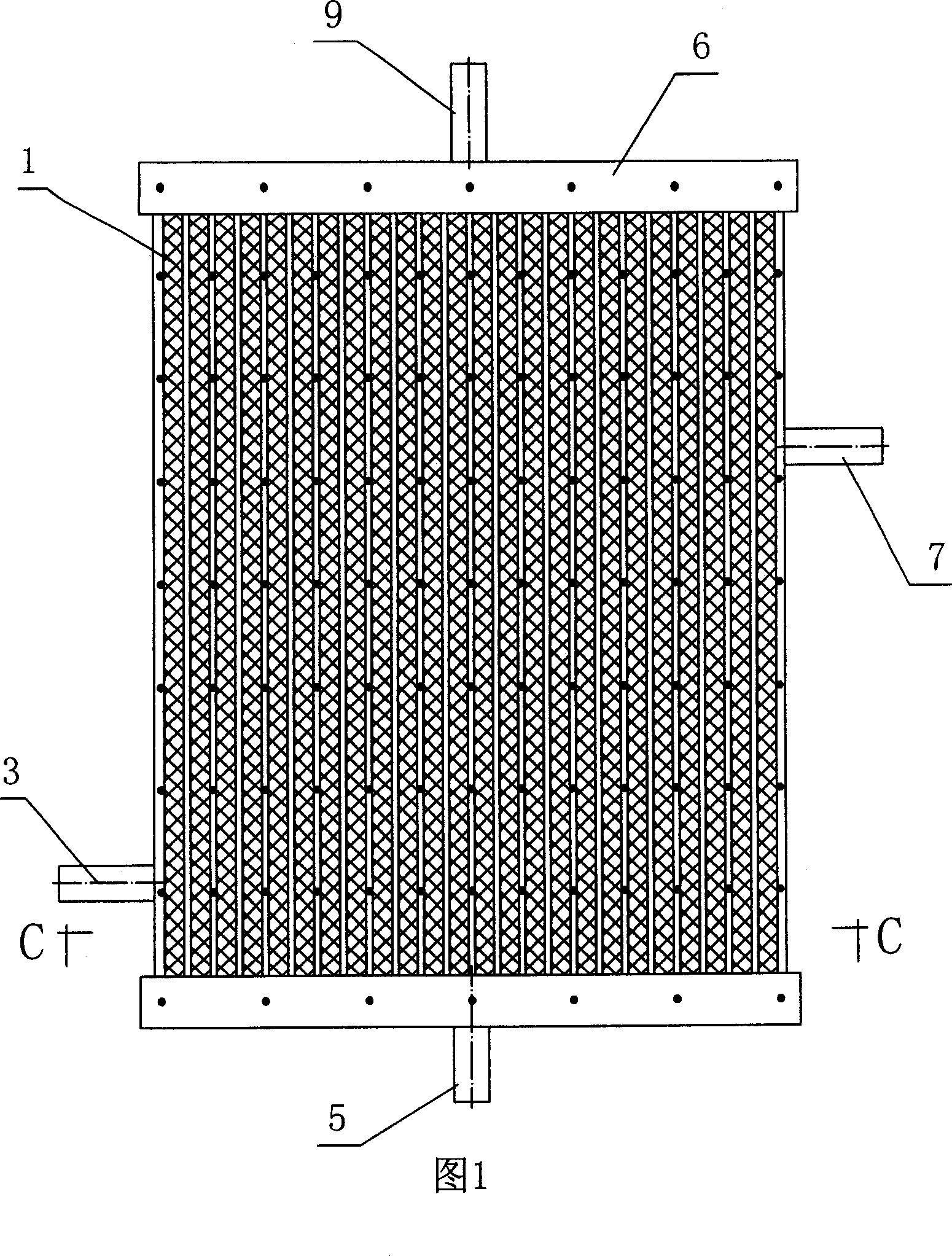

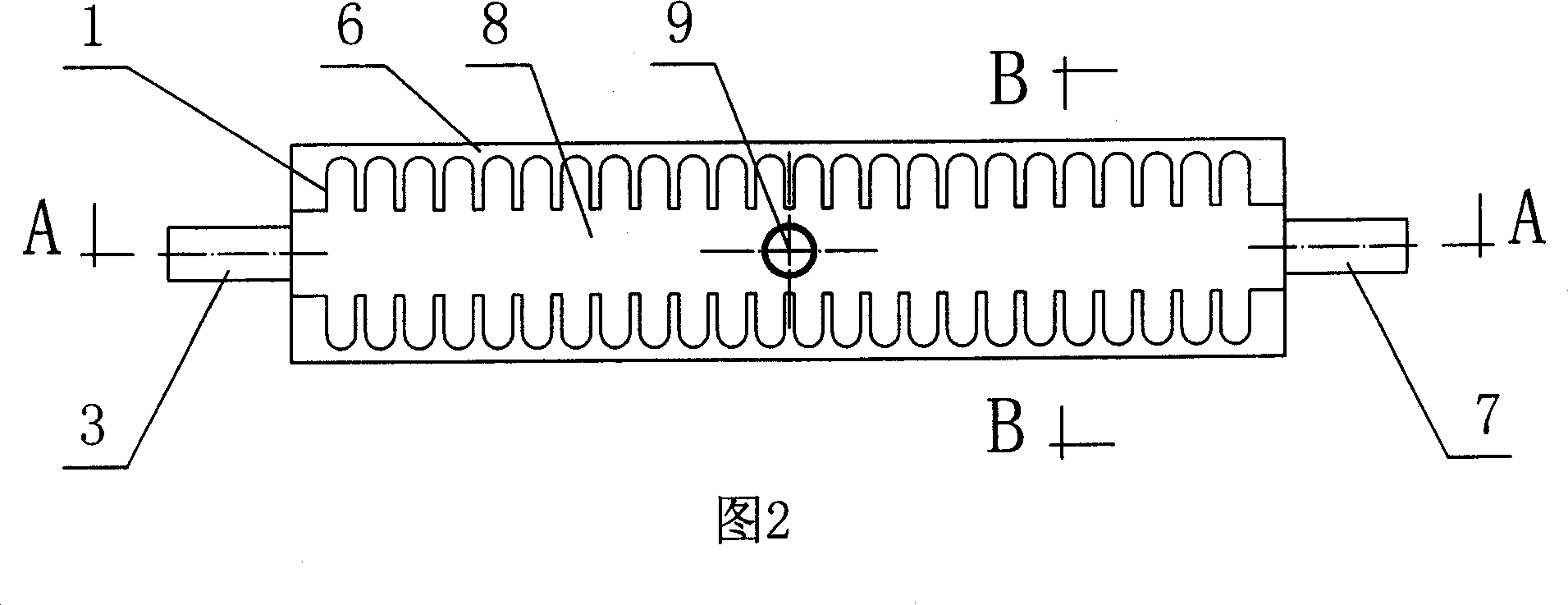

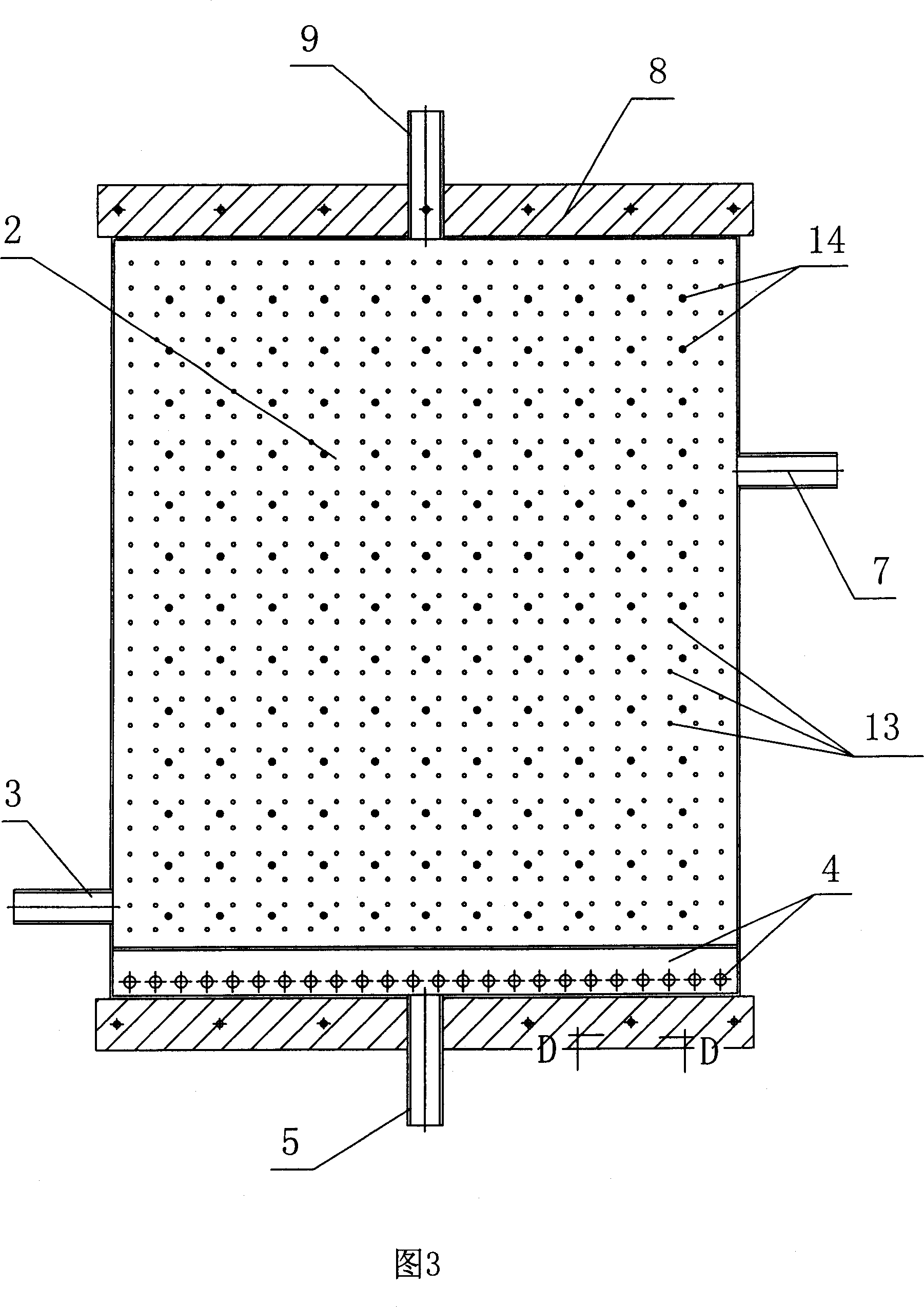

[0042] As shown in Figure 1-5, the dynamic microfiltration membrane module mainly includes a filter chamber 2 and a filter screen 1. There are micropores 13 with the same aperture on the front and rear walls of the filter chamber 2. The diameter of the micropores 13 is 0.5-5mm. The recoil water inlet pipe 3 is installed, the filter outlet pipe 7 is installed on the middle and upper part of the side, and the air exhaust pipe 9 is installed on the upper end. The backwash air distribution system 4 is connected, as shown in Figure 6, the backwash air distribution system 4 includes an air distribution pipe 10 and an aeration head 11, and the aeration head 11 is located at the lower end of the channel between the filter screen 1 and the filter chamber 2 on both sides of the air distribution pipe. The air distrib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com