Laser machining using an active assist gas

A kind of active, laser beam technology, applied in the direction of laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem that laser processing cannot produce high-speed manufacturing and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

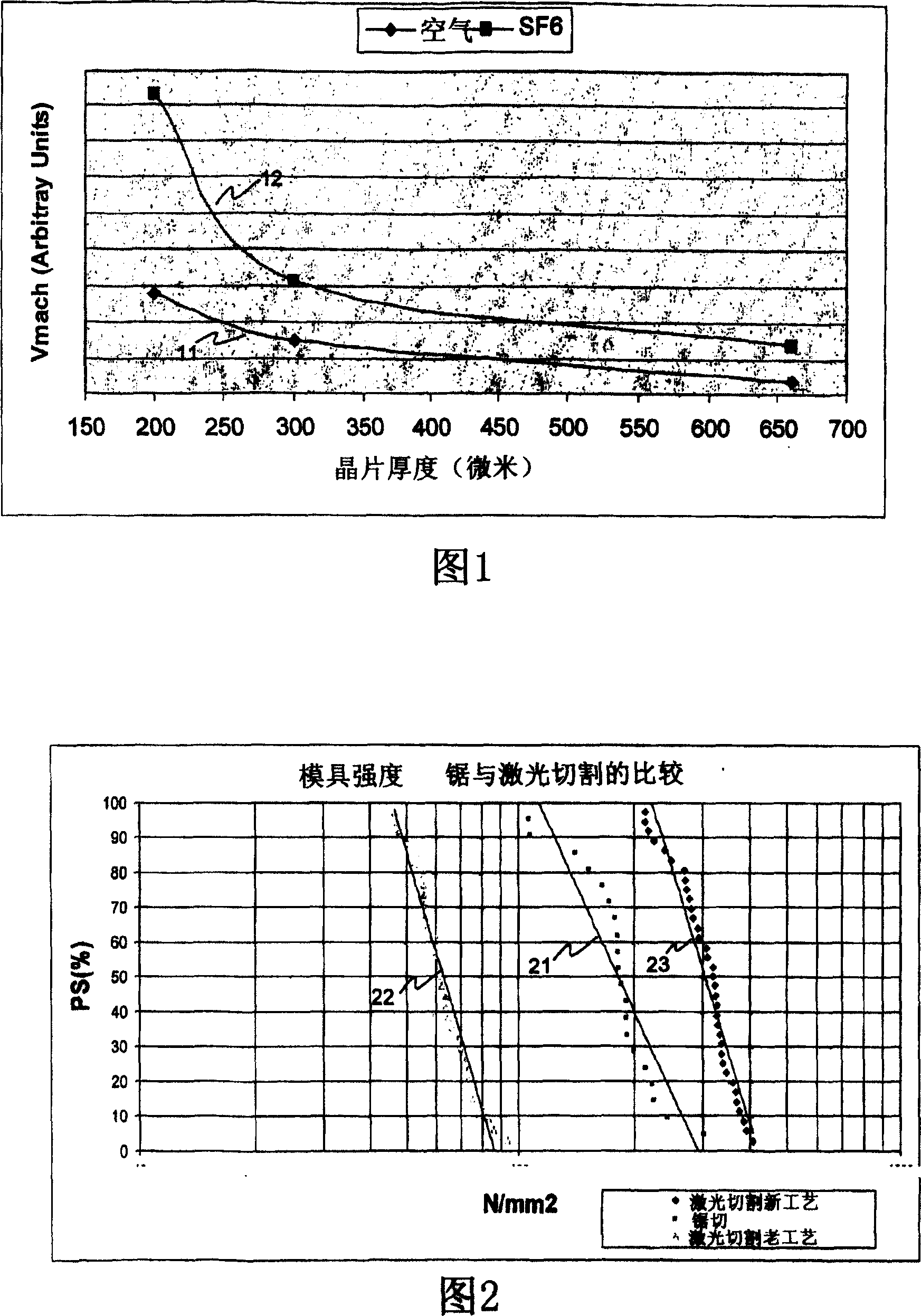

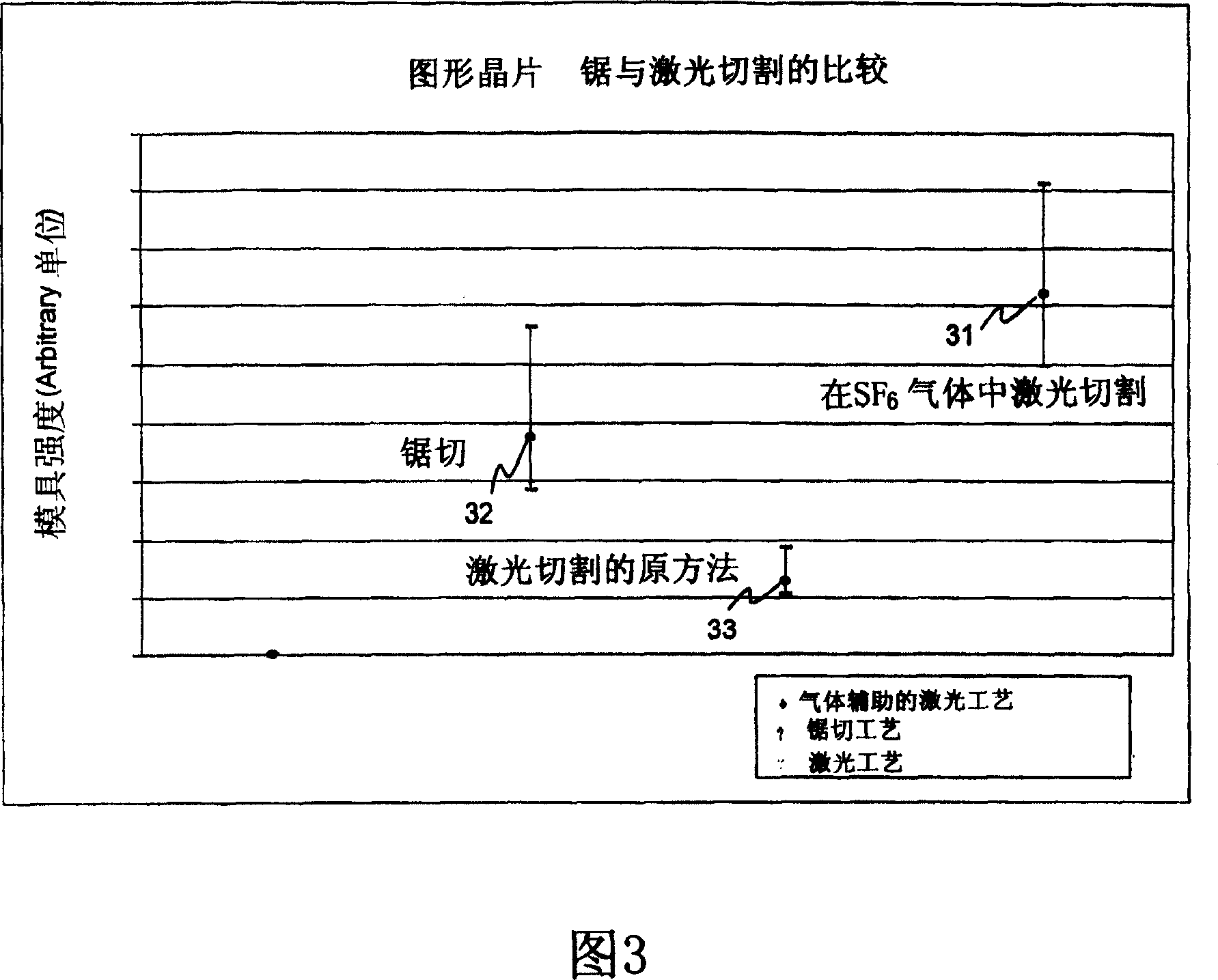

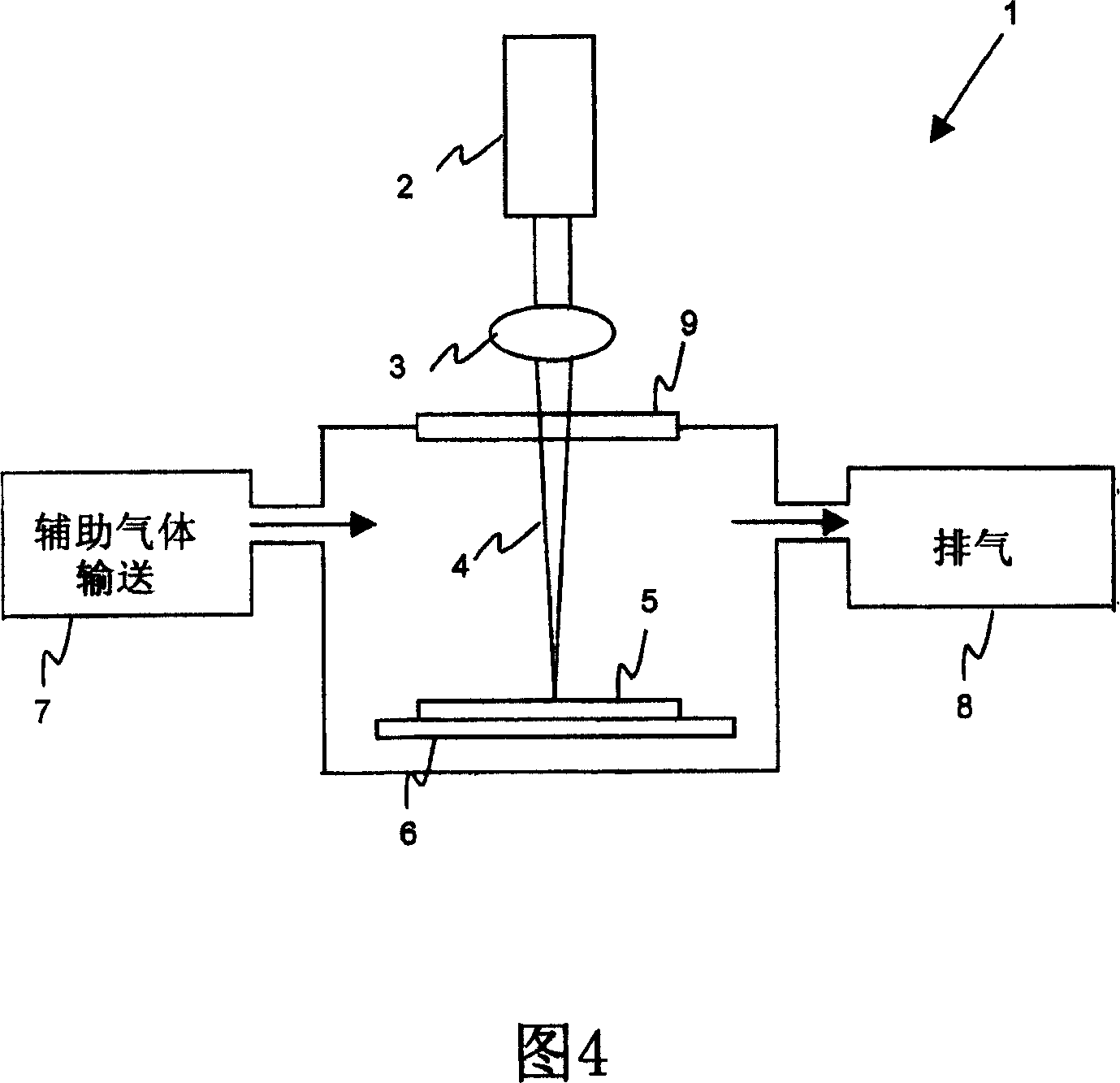

[0040] The invention specifically relates to the SF 6 Laser dicing of silicon substrates at ambient laser power densities above the silicon ablation threshold. Silicon material is mainly removed from the wafer substrate by laser ablation. SF 6 The addition of the laser cutting speed is increased, and the mold strength of the laser processing mold is also improved due to the improvement of the processing quality. This improvement can be used with prior art SF 6 improvement in etch compared to, that is, the SF 6 Part surfaces lasered in ambient are smoother than those lasered in air. However, in the present invention, the etching of silicon is substantially confined to the localized area of the workpiece where the laser is focused. In addition, the material ejected during laser ablation is closely related to SF 6 The environment reacts and can be removed from the processing site in gaseous form rather than redeposited as solid debris around the laser processing site.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com