Air generator for seat by a secondary driver

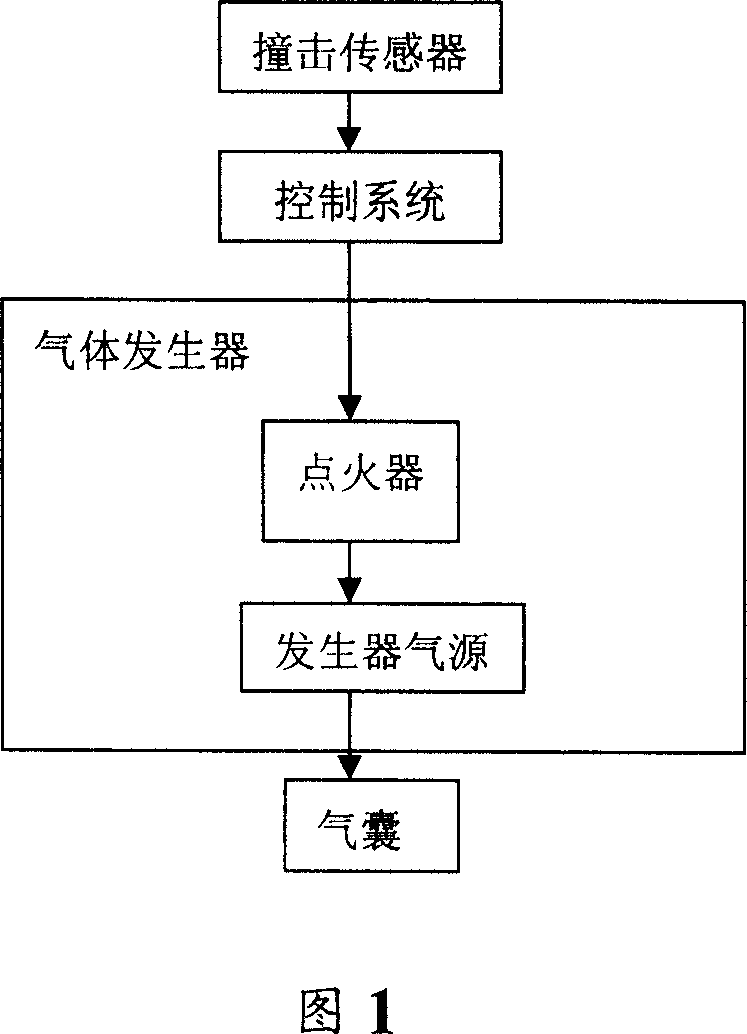

A technology of gas generator and gas generating agent, which is applied in vehicle safety arrangement, pedestrian/passenger safety arrangement, transportation and packaging, etc. It can solve problems such as difficult to control outlet pressure, blockage and damage of filter screen, and slow down the impact of high-temperature airflow The speed and outlet pressure are stable, avoiding the effect of too much pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

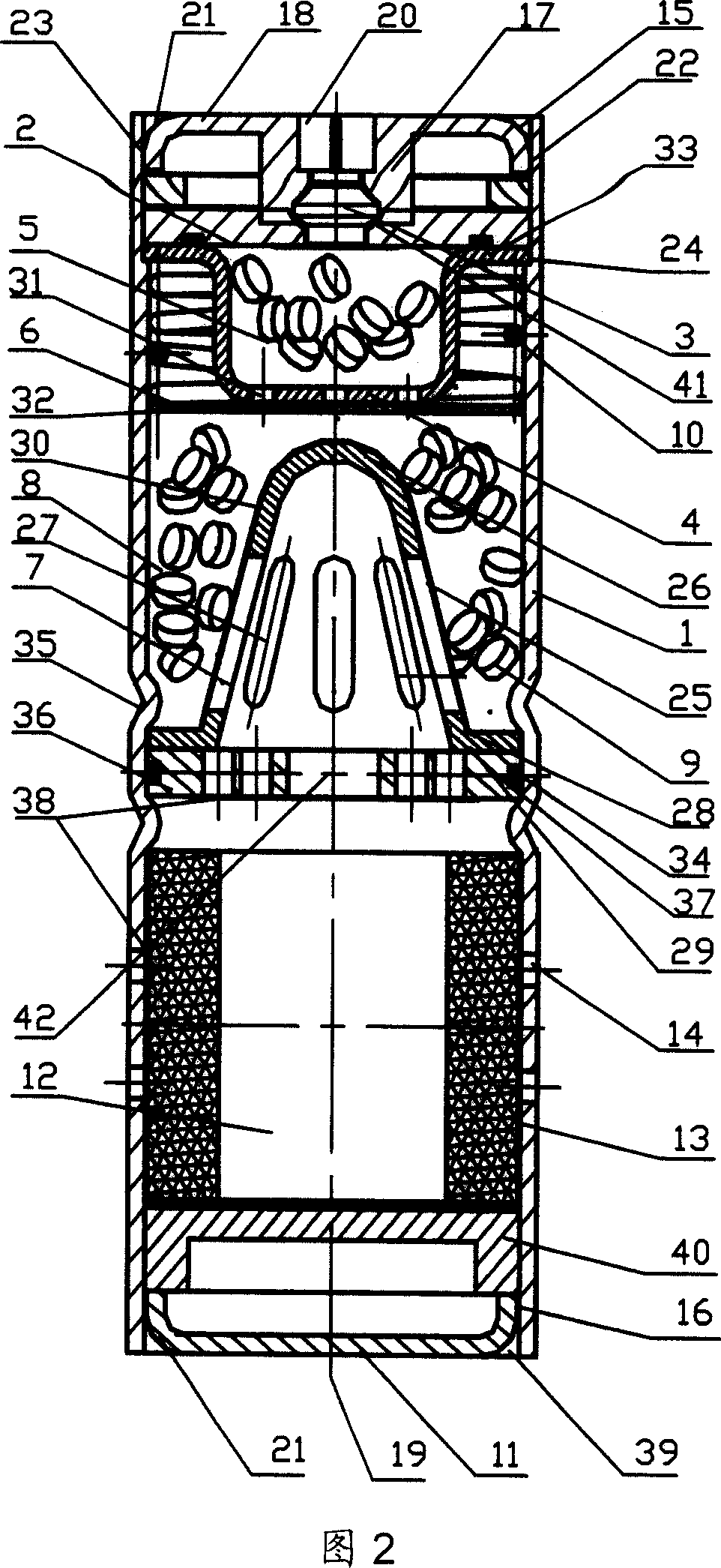

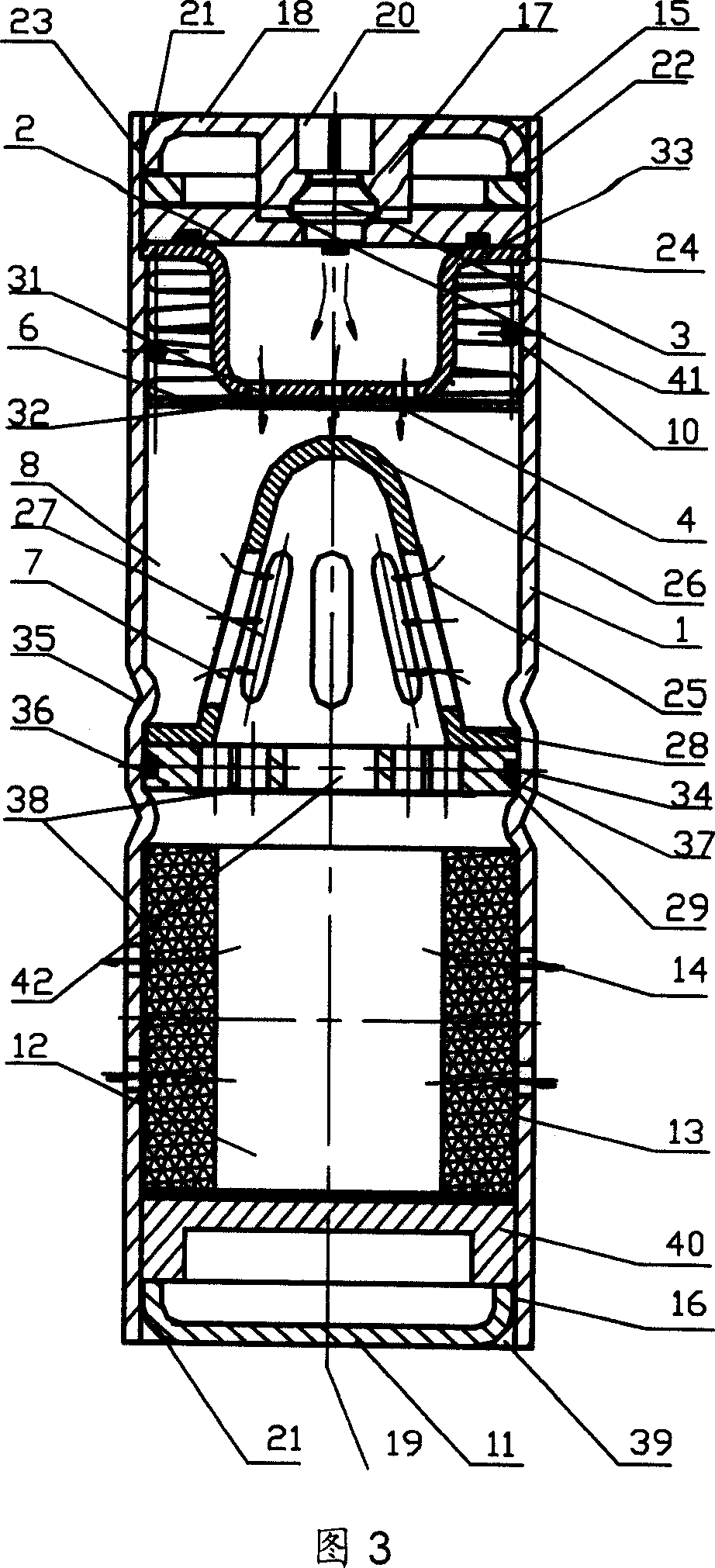

[0024] As shown in Figure 2, the present invention is made up of cylinder body 1 and the upper end cap 18 and the lower end cap 11 that are positioned at two ends of cylinder body 1, and upper end cap 18, lower end cap 11 and cylinder body 1 are welded into one by laser, and upper cover The top of 18 is flat, and there is a round hole 20 in the center at the position of the axis 19. The outer edge 21 of the cover is bent downward to form an axial annular section 23, which contacts with the inner side 22 of the cylinder to form a V-shaped welding groove 15. The lower end cover 11 It is a plane, perpendicular to the axial direction of the generator, and the outer circle of the lower end cover 11 is bent upward and axially to form an annular peripheral surface 16 that is closely matched with the inner side 22 of the cylinder body. V-shaped welding groove 39.

[0025] An ignition chamber 2 , a combustion chamber 8 and a filter chamber 12 are sequentially provided axially from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com