Oil gun

An oil gun and gun body technology, applied in the field of machine equipment lubrication and refueling, can solve the problems of no valve control of the suction hole, affecting the service life, simple structure of the sealing part, etc., to ensure the reliability of the piston, improve the sealing performance of the opening and the sealing good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

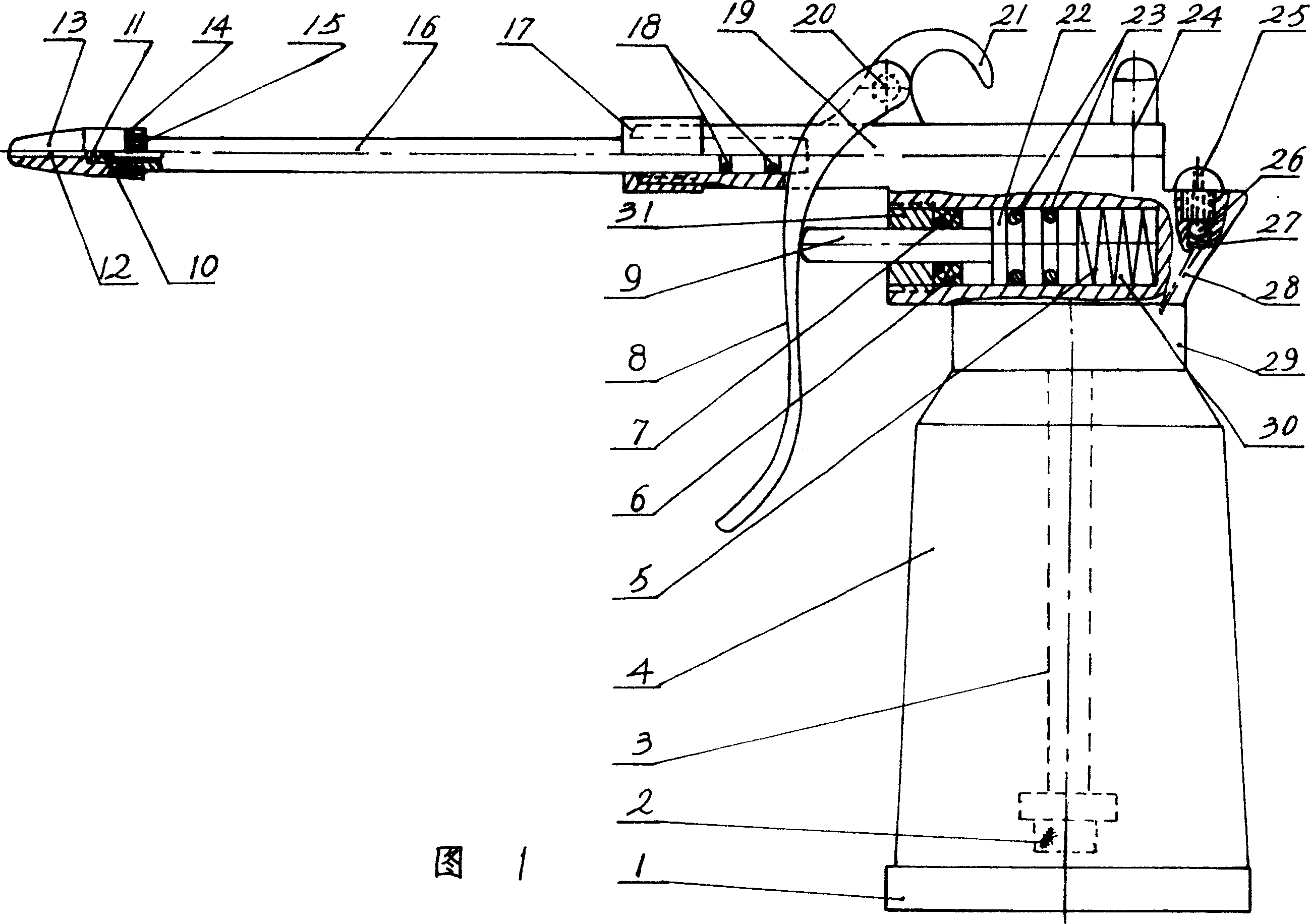

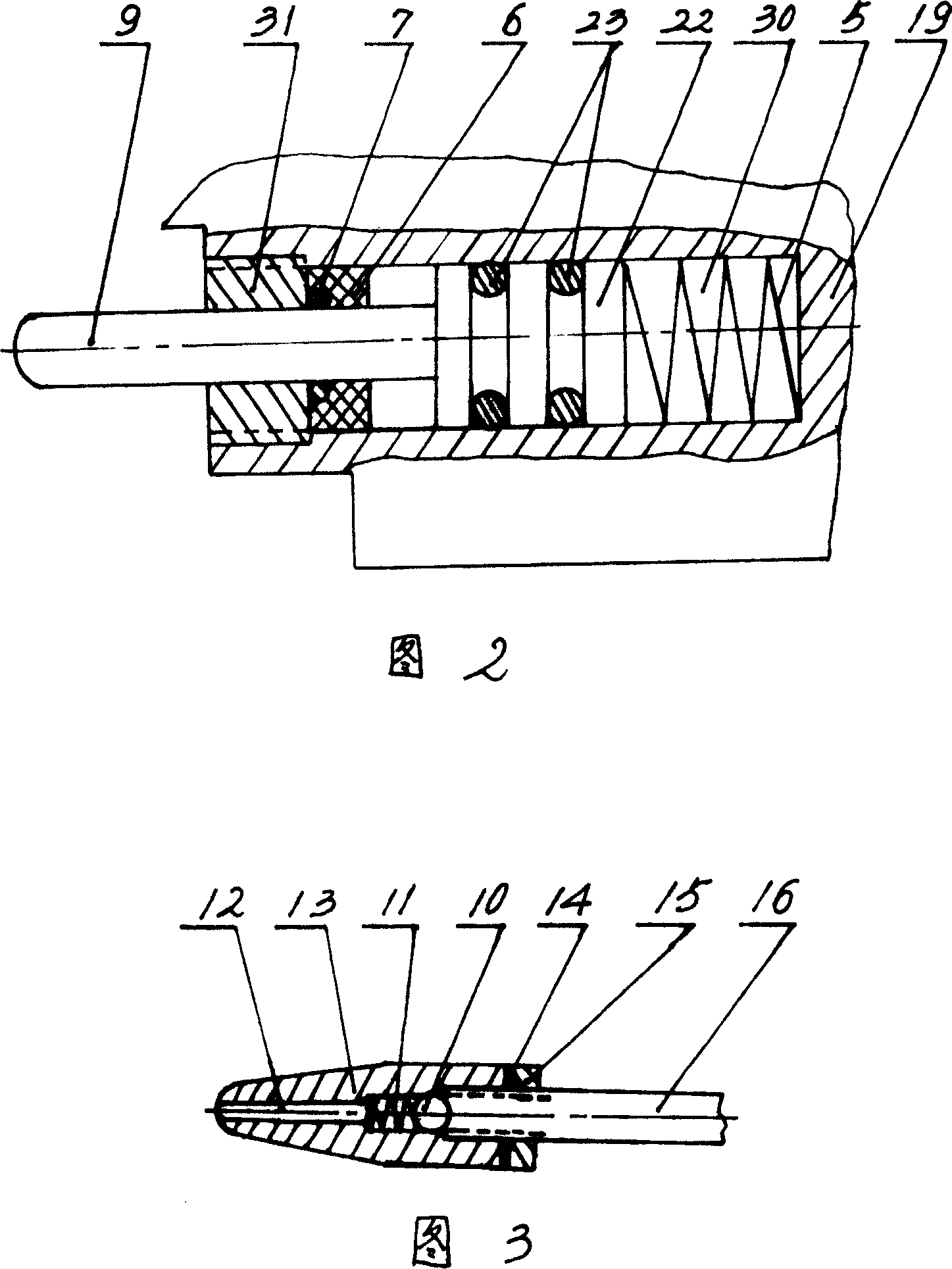

[0009] The invention discloses an oil gun, which has a gun body 19 with upper and lower segments (shell segments). The head of spray rod connects nozzle 13, is shaped on spray hole 12 in the nozzle, is shaped on oil injection piston cylinder 30 in the middle section of gun body, installs piston 22 and back-moving spring 5 in the oil injection piston cylinder, and connects the piston rod 9 of piston. Stretch out cylinder and cooperate with wrench 8, the lower section of gun body is connecting cap 29, and connecting cap links to each other with oil tank 4, so general gun barrel, oil filling piston cylinder and connecting cap are a whole, and oil tank is a single body, oil Suction pipe 3 is installed in the tank 4, and its opening of the structure of the oil injection piston cylinder 30 is the same direction as the spray bar nozzle 13, as shown in Figure 1, a screw plug 31 is installed in the opening, and a retaining ring 6 and a sealing ring 7 are arranged to prevent The oil tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com