Parallel on-line fuzzy adaptive glue compounding and applying control method and system for man-made board

A fuzzy self-adaptive, parallel online technology, applied in the direction of manufacturing tools, adhesive application devices, and pretreatment of molding materials, can solve problems such as poor work reliability, large system errors, and low precision of glue adjustment and control, and achieve precise control , accurate flow, and good dynamic response characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific implementation mode 1: Particleboard adjustment and sizing control

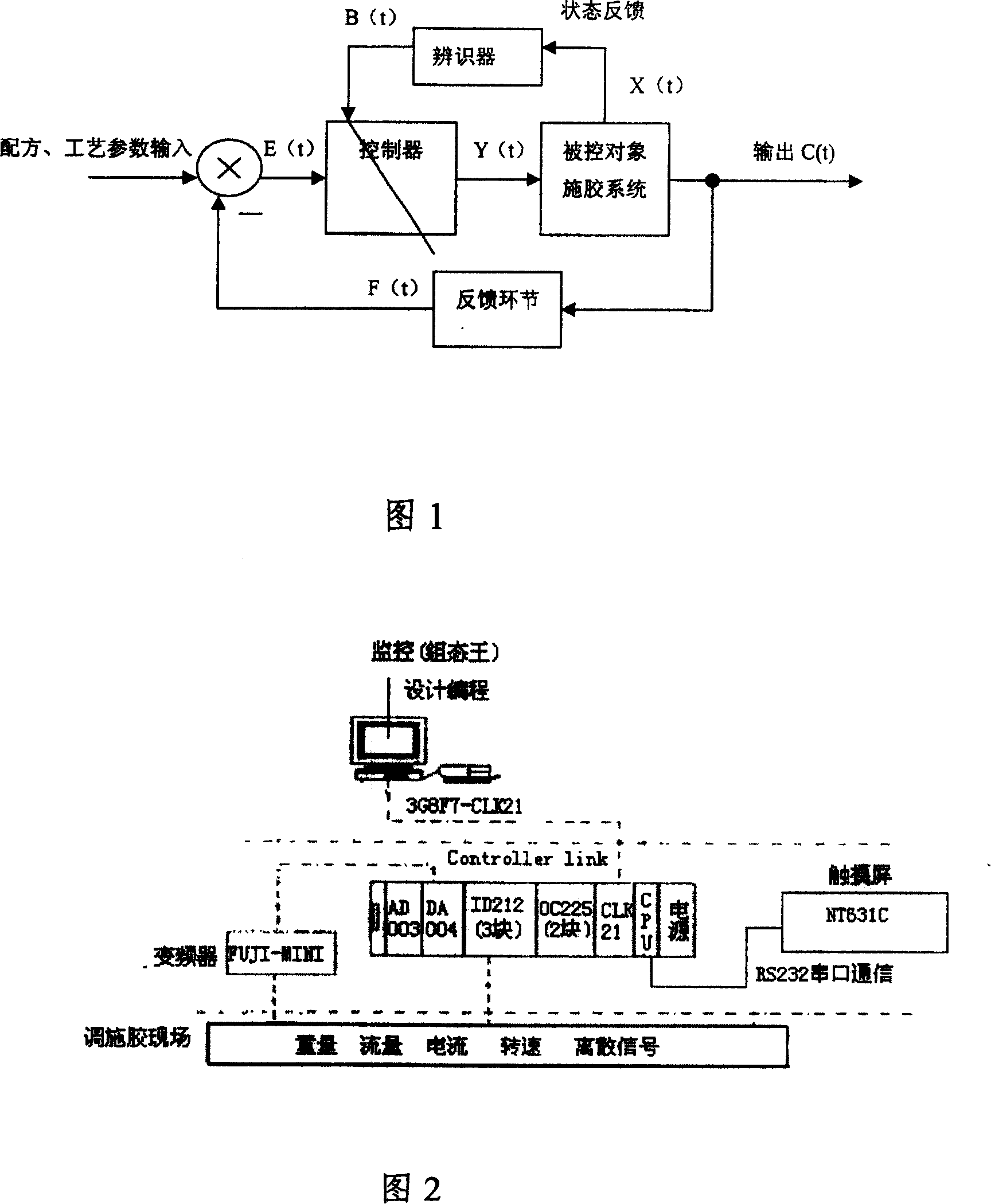

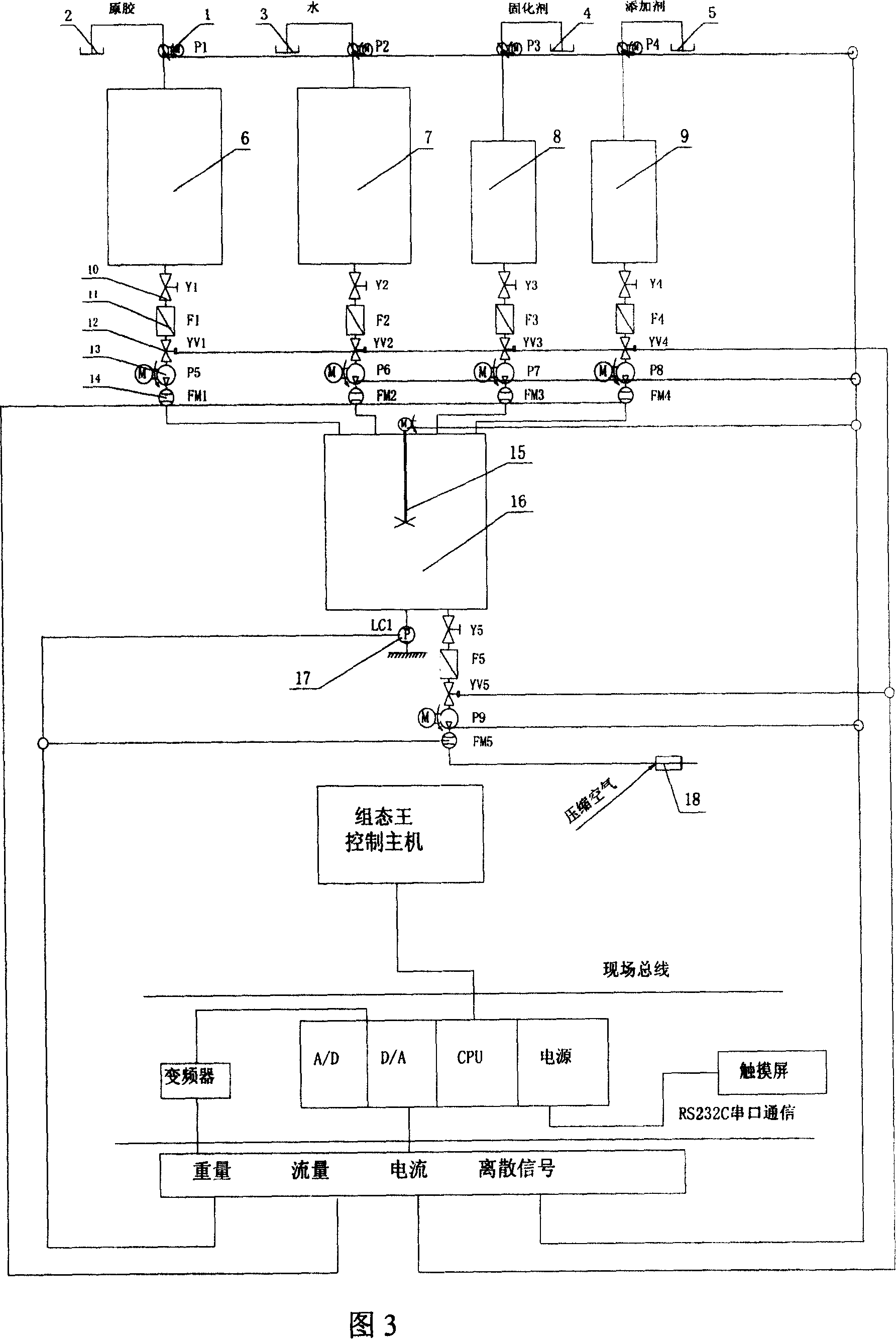

[0019] The control system of the present invention includes two parts: a parallel online glue dispensing device and a fuzzy adaptive control system. The parallel online glue dispensing device includes a gear pump 1, a raw glue constant temperature control device 19, a pipeline 20, a liquid level sensor 21, and N raw materials A raw material storage tank group composed of storage tanks, a stirring mechanism 15, a glue mixing storage tank 16, a weight sensor 17, a parallel glue adjustment mechanism and an online glue sizing mechanism, nozzles 18, etc. The raw material storage tank group made of stainless steel includes raw rubber storage tank 6, water storage tank 7, additive storage tank 8, curing agent storage tank 9, 4 gear pumps 1 and each of the raw material storage tank group respectively through the raw material input pipeline 20 The inlets of the storage tanks 6, 7, 8, and 9 are connecte...

specific Embodiment approach 2

[0021] Specific implementation mode 2: dry-process fiberboard first applied and then dried to adjust glue control

[0022] The control system is the same as above, and the process is as follows: First, the system transports the original rubber, water, additives, curing agent, etc. to their respective storage tanks through the gear pump, and keeps the original rubber at normal temperature (generally 20°C) by controlling the temperature adjustment device; Then the system continuously and automatically measures according to a certain ratio according to the process formula through independent metering systems such as respective pipelines, speed-regulating pumps, and flow meters. The glue mixing tank is connected to the output pipeline, and the glue is sent to the fiber drying pipeline through the speed-regulating pump and flowmeter, so as to realize quantitative and continuous online sizing of the glue according to the amount of fiber conveyed by the heat mill screw feeder; the dri...

specific Embodiment approach 3

[0023] Specific implementation mode 3: The dry-process fiberboard is first dried and then sizing and sizing control

[0024]The control system is the same as above, and the process is as follows: First, the system transports the original rubber, water, additives, curing agent, etc. to their respective storage tanks through the gear pump, and keeps the original rubber at normal temperature (generally 20°C) by controlling the temperature adjustment device; Then the system continuously and automatically measures according to a certain ratio according to the process formula through independent metering systems such as respective pipelines, speed-regulating pumps, and flow meters. The glue mixing tank is connected with the output pipeline, and the glue is sent to the fiber glue mixing machine or the drying pipeline through the speed-regulating pump and flow meter, so as to realize quantitative continuous online sizing according to the proportion of raw materials. The fiber weighing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com