Continuous chloroparaffin production apparatus

A production device, chlorinated paraffin technology, applied in the field of continuous chlorinated paraffin production device, can solve the problems of high chlorine content, production accidents, low chlorine conversion rate, etc., and achieve the effect of avoiding production accidents and preventing excessive heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

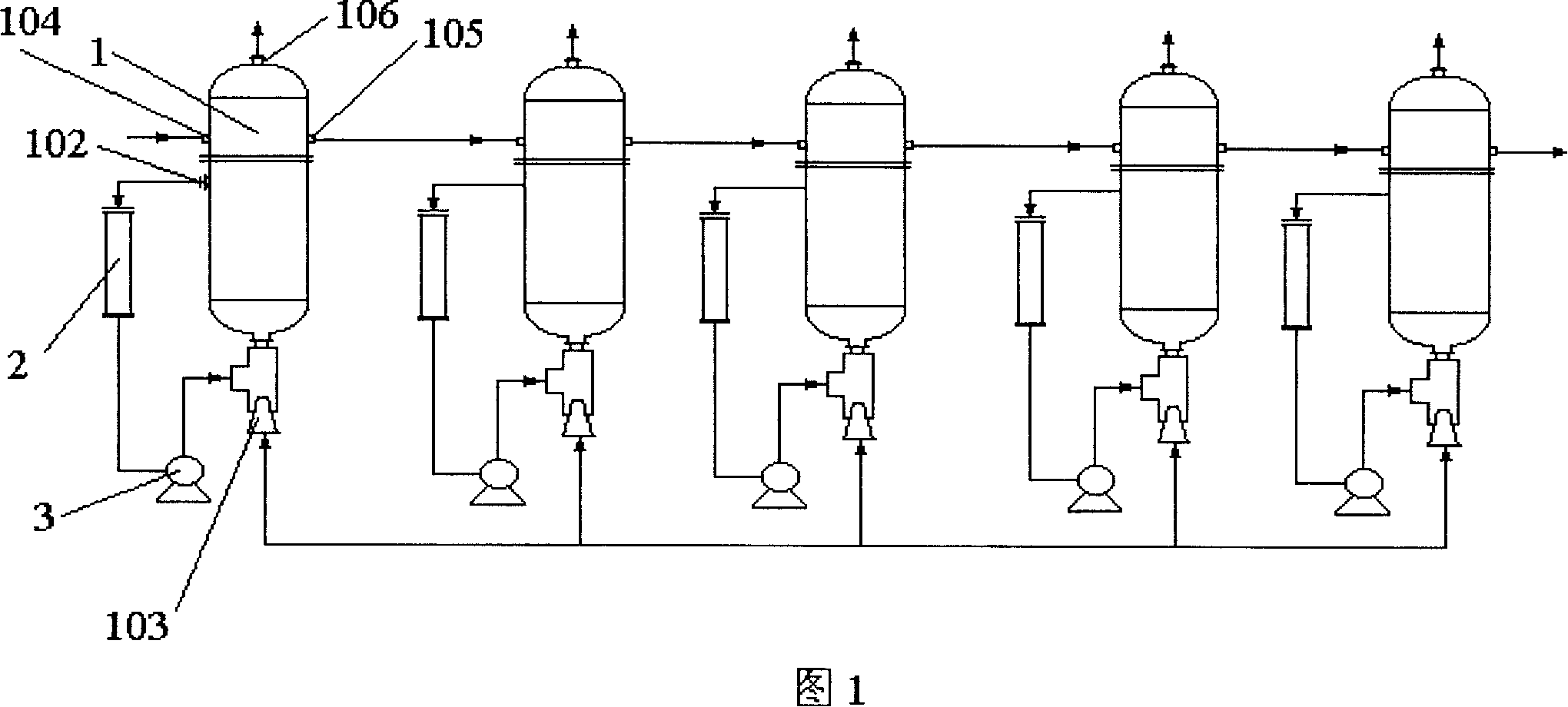

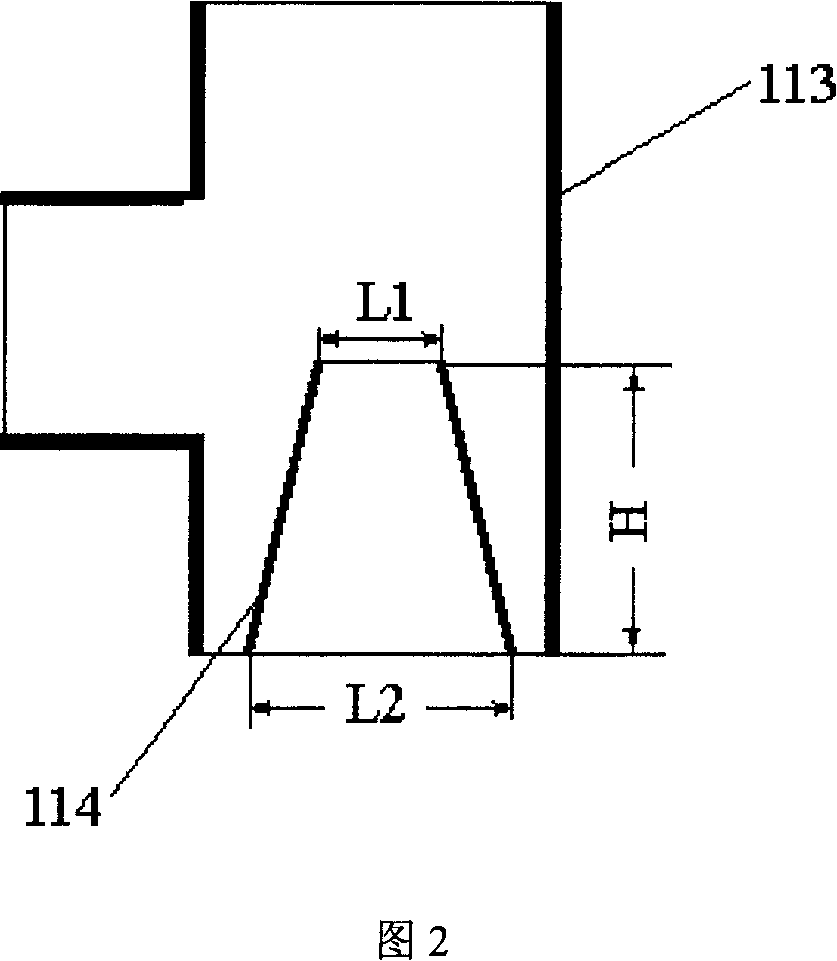

[0030] Adopt the device of Fig. 1, the reactor of Fig. 2 and the nozzle of Fig. 3, there are 5 reactors, prepare chlorinated paraffin.

[0031] The height H of the trapezoidal tube is 300 mm, the length of the upper bottom L1 is 50 mm, and the length L2 of the lower bottom is 100 mm.

[0032] The paraffin oil enters the reactor continuously through the paraffin oil inlet, and the chlorine gas enters the reactor from the bottom of the reactor through the circulating material and the chlorine gas inlet device. Under the catalysis of the ultraviolet light emitted by the ultraviolet lamp, the chlorination reaction is carried out, and the reaction product of the upper stage Enter the reactor of the next stage to continue the reaction. The reaction product of the last reactor enters the subsequent section for refining, and the hydrogen chloride produced by the reaction enters the tail gas treatment system from the tail gas outlet at the top of the reactor;

[0033] The reaction prod...

Embodiment 2

[0041] Adopt the device identical with embodiment 1, prepare chlorinated paraffin, select 3 reactors for use.

[0042] The technological conditions of the reaction are as follows: the reaction temperature is 105°C, the reaction pressure is 0.04Mpa, and the flow rate of paraffin oil is 1.875m 3 / h, the flow rate of chlorine gas is 800m 3 / h, the volume ratio of circulating material to chlorine gas is:

[0043] Circulating material: chlorine = 1:20;

[0044] The residence time of the material in the reactor is 25 hours,

[0045] The power of the ultraviolet lamp is 5 kW;

[0046] The average chlorine content gradient of the materials between each reactor is 20%, so as to ensure that the discharge of the last reactor reaches the specified index, and the specific gravity of the materials of each reactor is as follows:

[0047] The second reactor: 18 (70°C Bomido), the third reactor: 27 (70°C Bomido); the molecular weight of paraffin oil is 200. The conversion rate was 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com