Production method of in-out dual purpose gas-liquid conveying hose and solid core rod mould used in production

A technology for conveying hoses and molds, which is applied in the field of combined hard mandrel molds and the production of flexible hoses with the same, can solve the problems of difficulty in releasing the hard mandrel mold, poor negative pressure resistance of hoses, and high energy consumption of vulcanization equipment , to achieve the effect of saving power equipment, good resistance to positive and negative pressure, reducing pollution and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

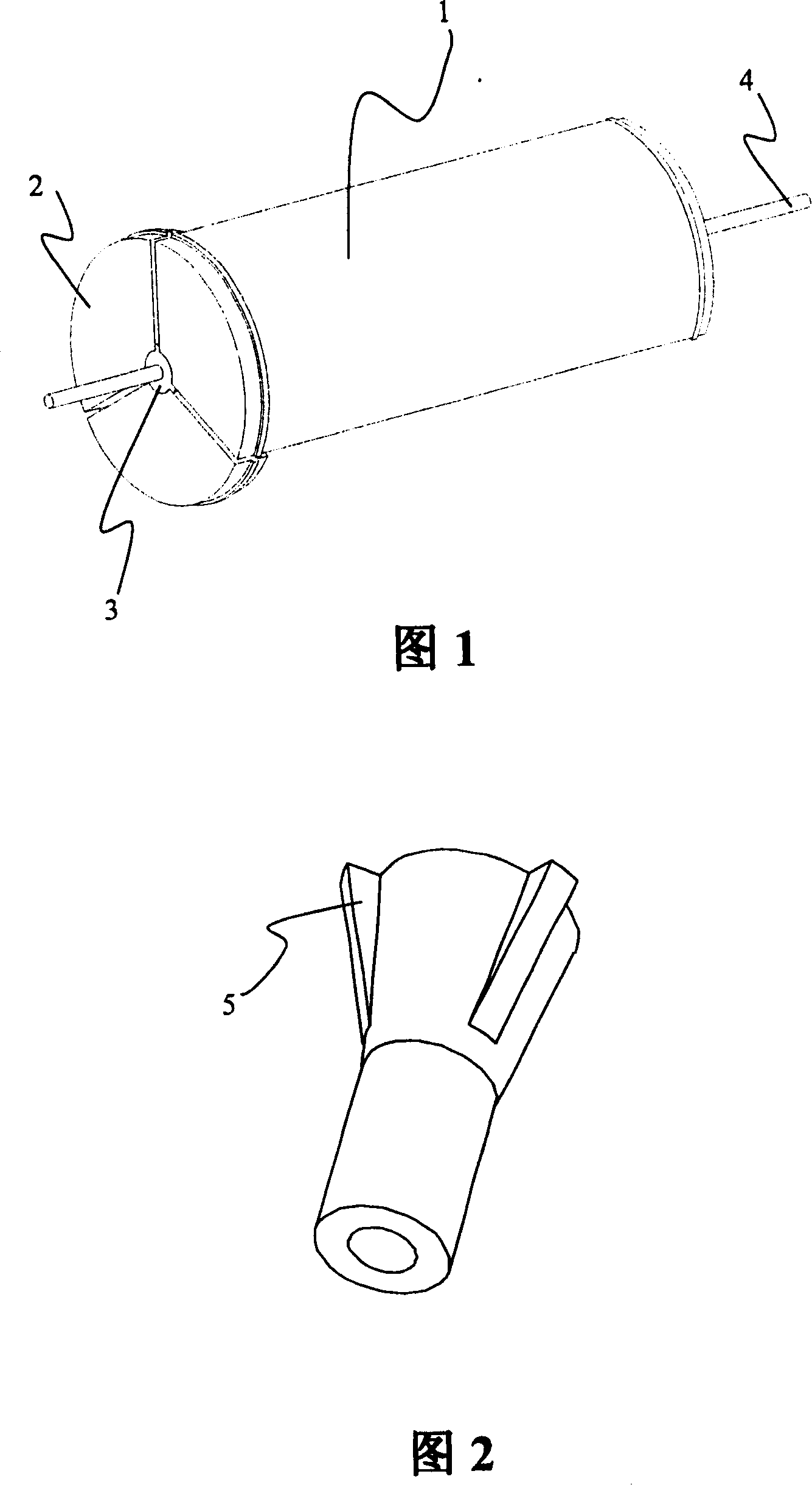

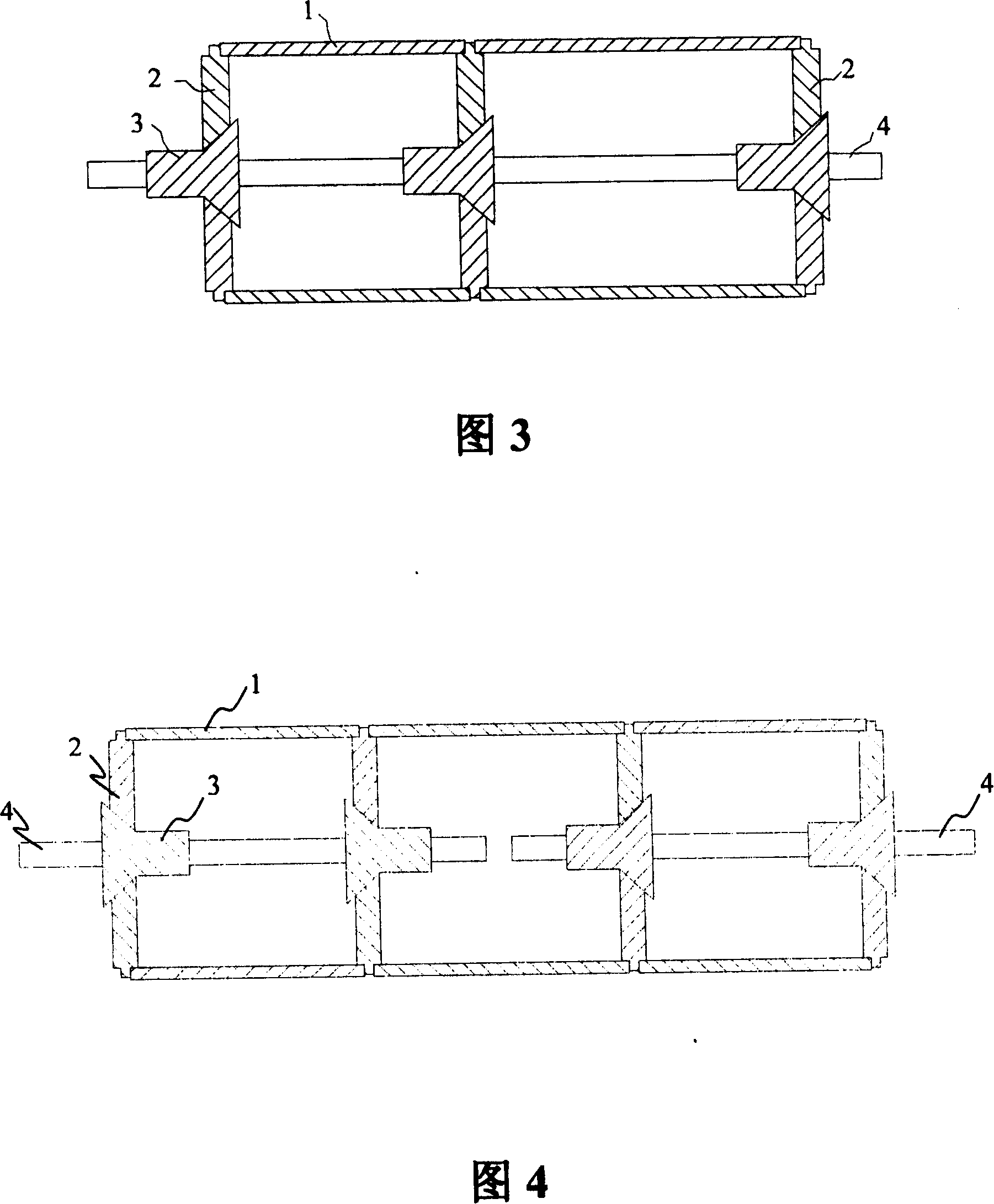

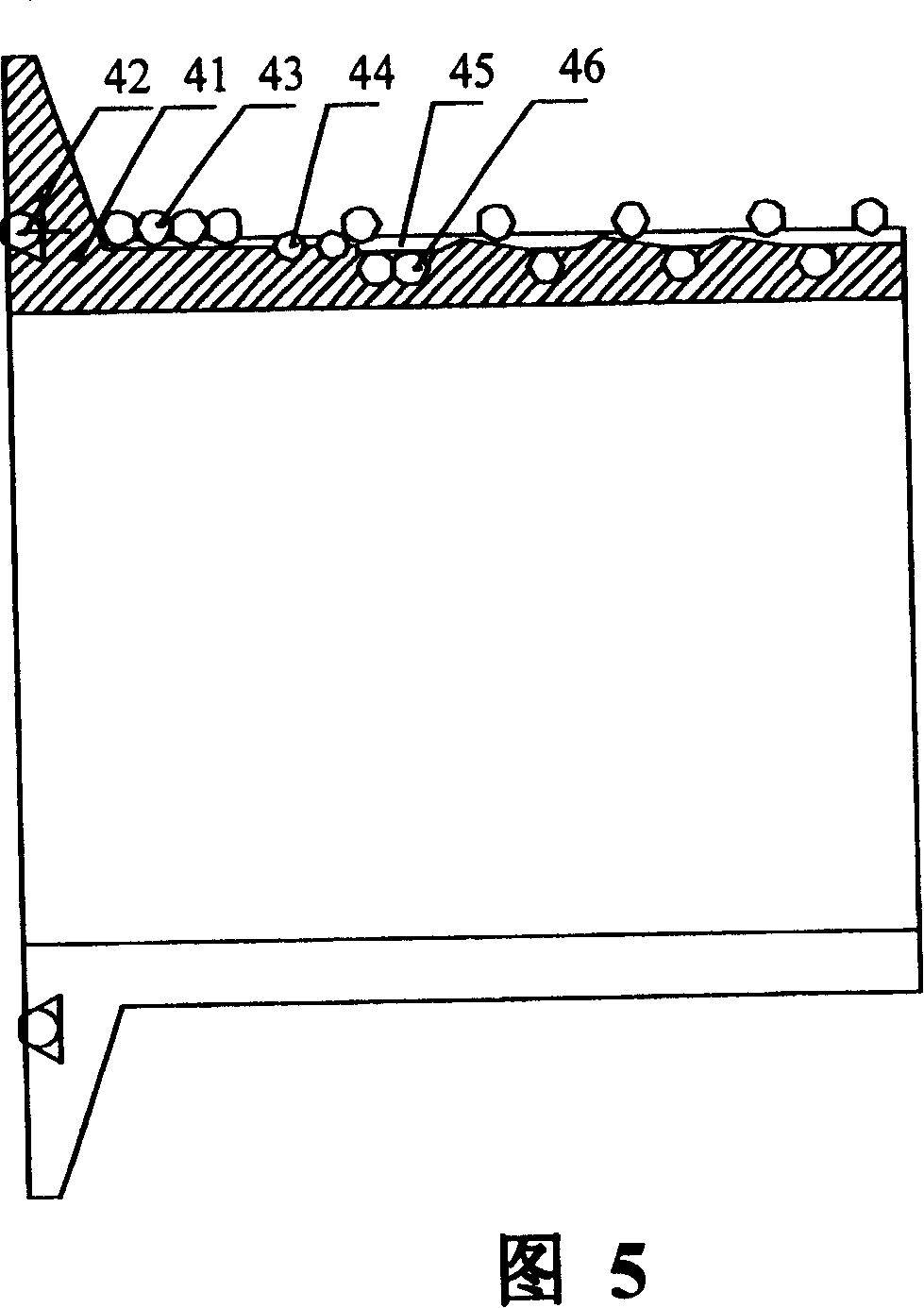

[0037] The invention discloses a hard mandrel mold for producing a dual-purpose gas-liquid conveying flexible hose. Fig. 1 is a schematic diagram of an embodiment of the hard mandrel mold of the present invention. The mandrel mold is a three-lobed type. Mainly include in Fig. 1: 120 ° arc-shaped steel plate 1, 120 ° fan-shaped connecting steel piece 2, positioning cone 3, connecting rod 4, Fig. 2 is the positioning cone schematic diagram of hard mandrel mold embodiment of the present invention, comprises Locate the bump 5.

[0038] Figure 2 is a schematic diagram of the positioning cone of the embodiment of the combined hard mandrel mold of the present invention. The conical surface of the positioning cone 3 is provided with three positioning projections 5, and the fan-shaped connecting steel block 2 is located between the two positioning projections 5. Each fan-shaped connection steel block corresponds to a fixed connection with an arc-shaped steel plate, and the fixed conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com