Method for manufacturing metallic products and product thereof

A manufacturing method and metal technology, applied in the metal product manufacturing method and its product field, can solve the problems of unsightly, increased production cost, and uneven surface roughness, so as to improve the quality rate and productivity, reduce the rework rate, and reduce the paint The effect of layer burst defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

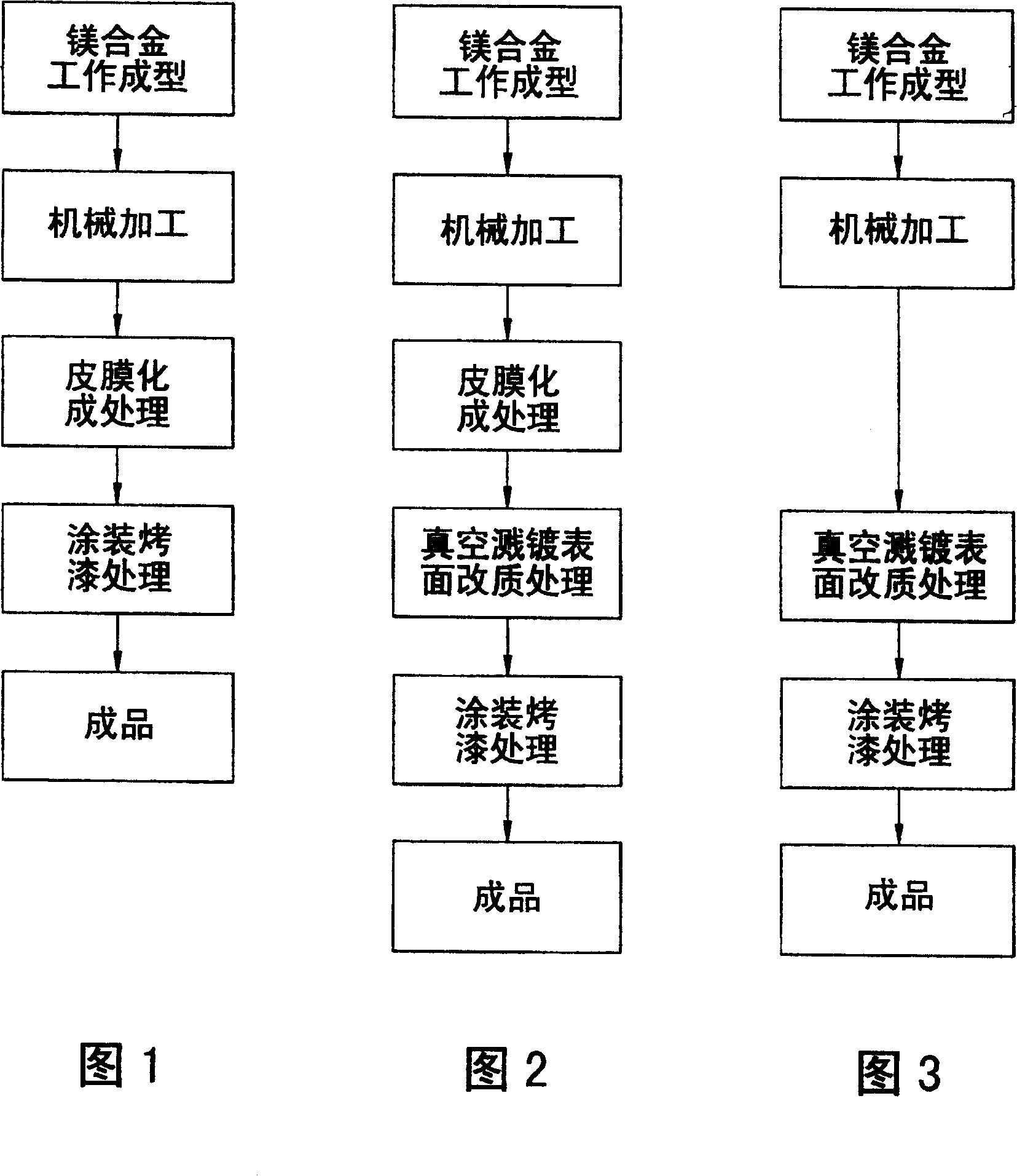

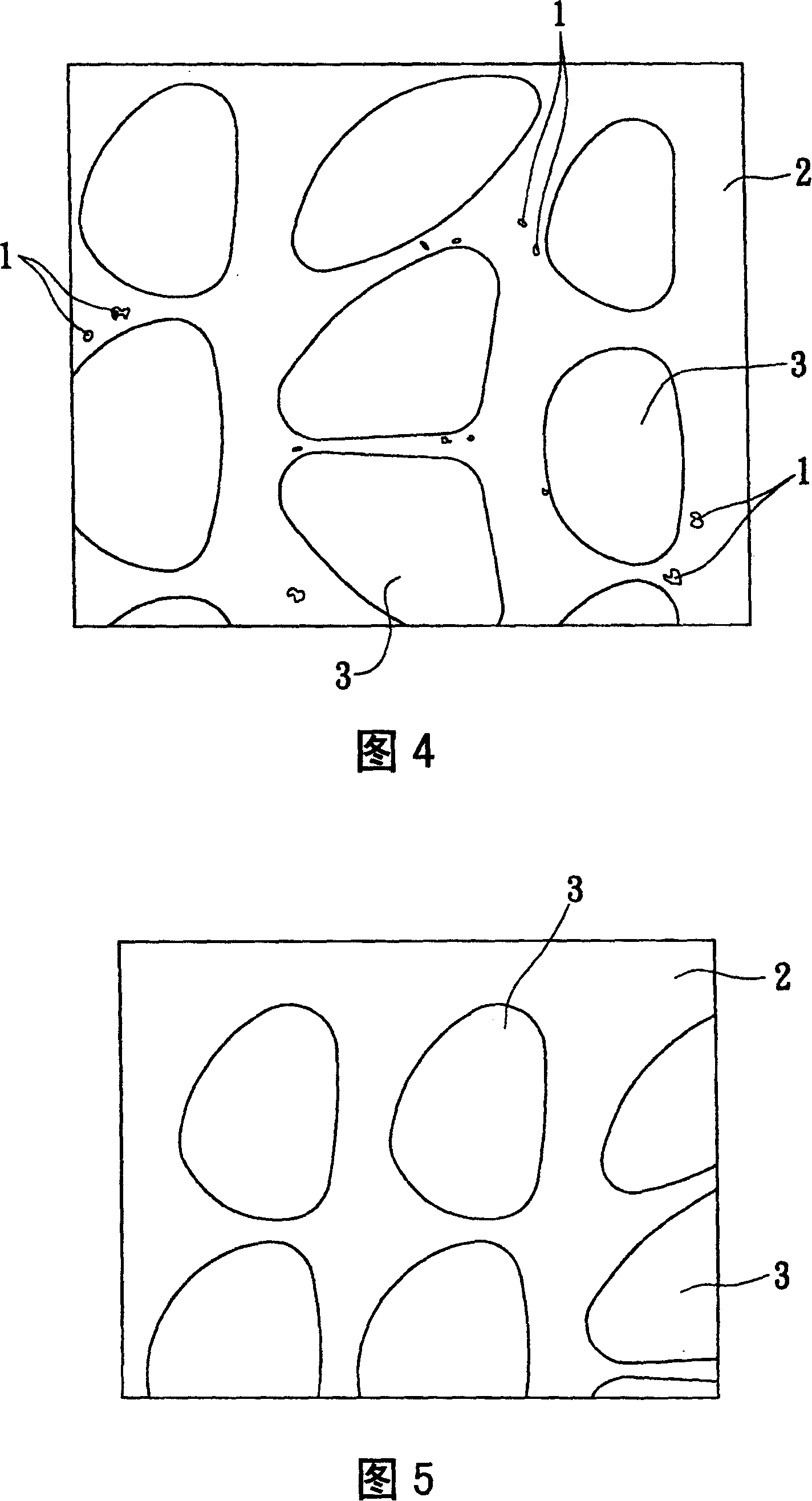

[0038] As shown in Fig. 1, Fig. 2 and Fig. 3, it is the production process of magnesium alloy workpiece after the traditional film formation and paint baking treatment, and the vacuum sputtering introduced by the present invention is applied after the film formation and before the paint baking treatment. A schematic diagram of the process of surface modification, and then the final coating and baking paint treatment. As shown in Figure 5 (the surface of the product of the present invention) and Figure 4 (the surface of the known product), it is a schematic diagram of the final product obtained by the two processes, wherein the surface defect 1 shown in Figure 4 will cause coating and baking paint defects . The magnesium-aluminum alloy body 2 may be a structure with a complex shape, such as a hollow portion 3 and the like. Therefore, from the comparison of FIG. 4 and FIG. 5 , the effect of the present invention for improving the surface properties of magnesium alloy products c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com