Method for measuring parallel beam injection angle

A technology of injection angle and measurement method, applied in the field of parallel beam injection angle measurement, to achieve the effects of easy operation, accurate measurement and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail below in conjunction with specific embodiment:

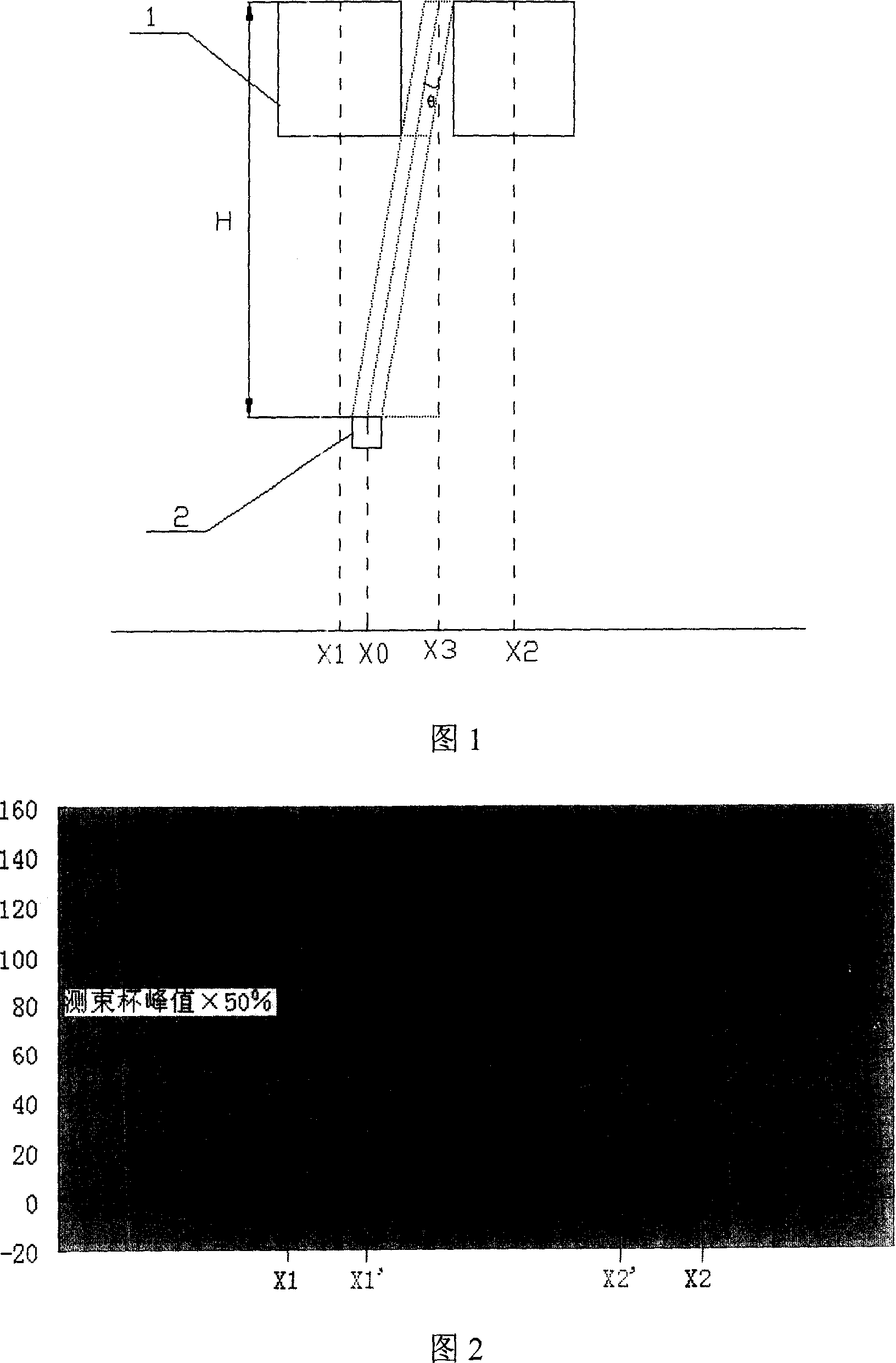

[0015] As shown in Figure 1, after the ion beam is swept away by the scanning power supply, it comes out of the parallel beam lens and the accelerating field and is injected into the wafer. One or more measuring beam Faraday 2s are set at the wafer position, and the Faraday 1 beams are moved from left to right. Move to the right, according to the parallel beam angle measurement formula, the parallel beam injection angle at the Faraday position of the measuring beam can be measured.

[0016] Parallel beam angle measurement formula:

[0017] As shown in Figure 1, the moving Faraday 1 moves from left to right. When the moving Faraday 1 moves to the position X1, the beam current measured by the measuring beam Faraday 2 begins to decrease. When the moving Faraday 1 moves to the position X2, the measuring beam Faraday 2 The measured beam current returns to its maximum value....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com