Replacing method of valv device, processing system and sealing components

A technology for sealing parts and gate valves, applied in valve devices, lift valves, sliding valves, etc., can solve the problems of prolonging the vacuuming time, reducing production capacity, and reducing the utilization rate of devices, and achieving the effect of improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

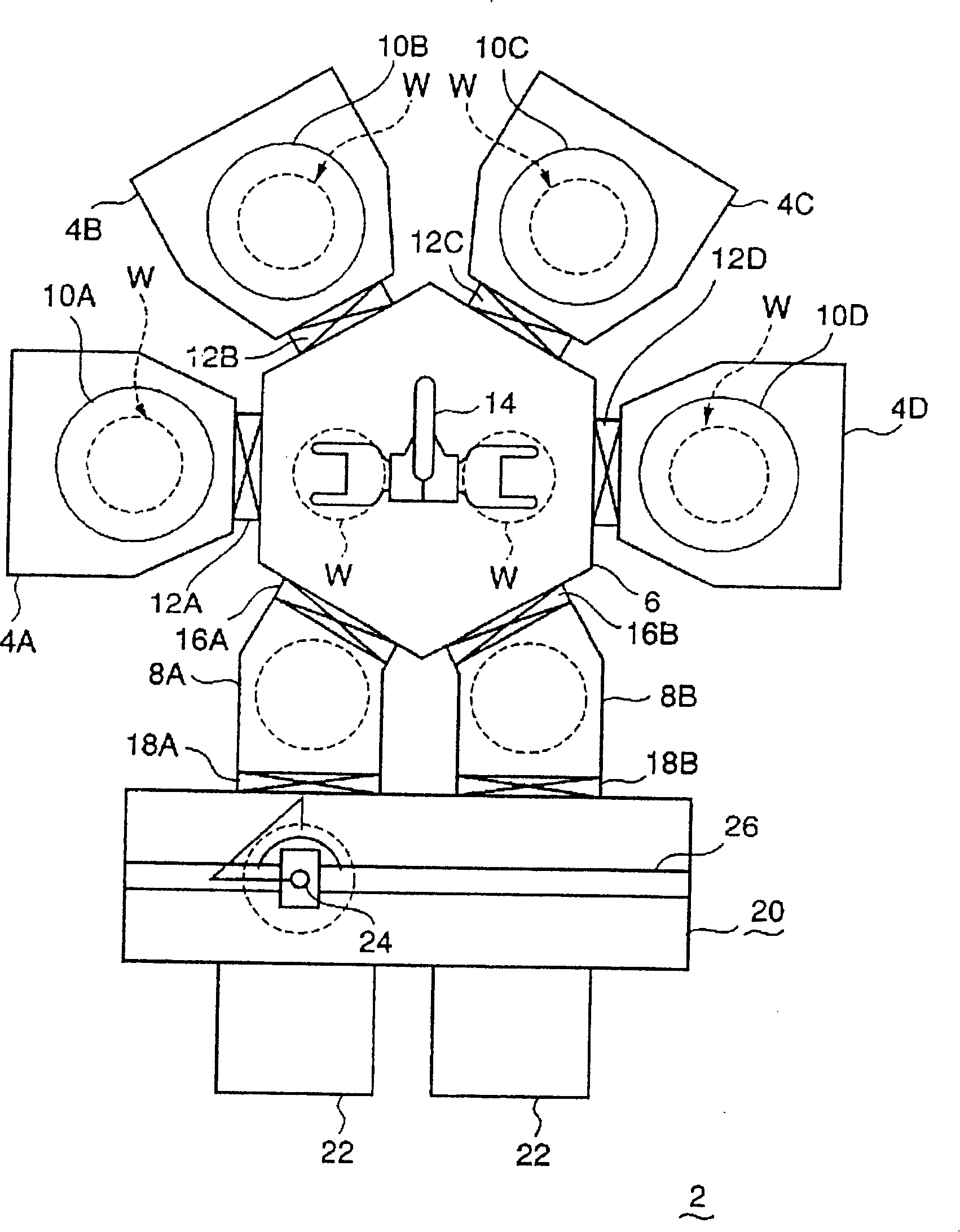

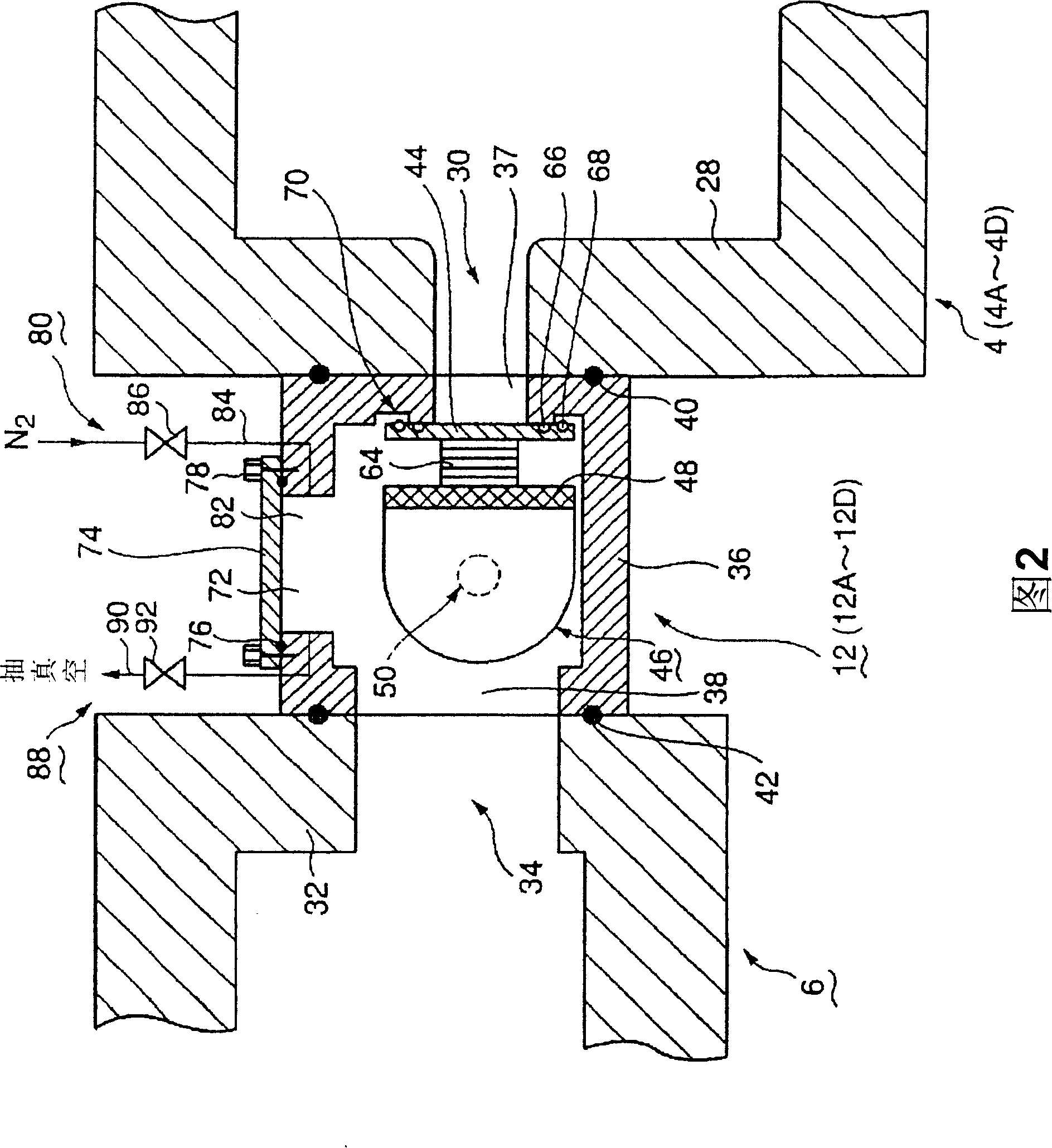

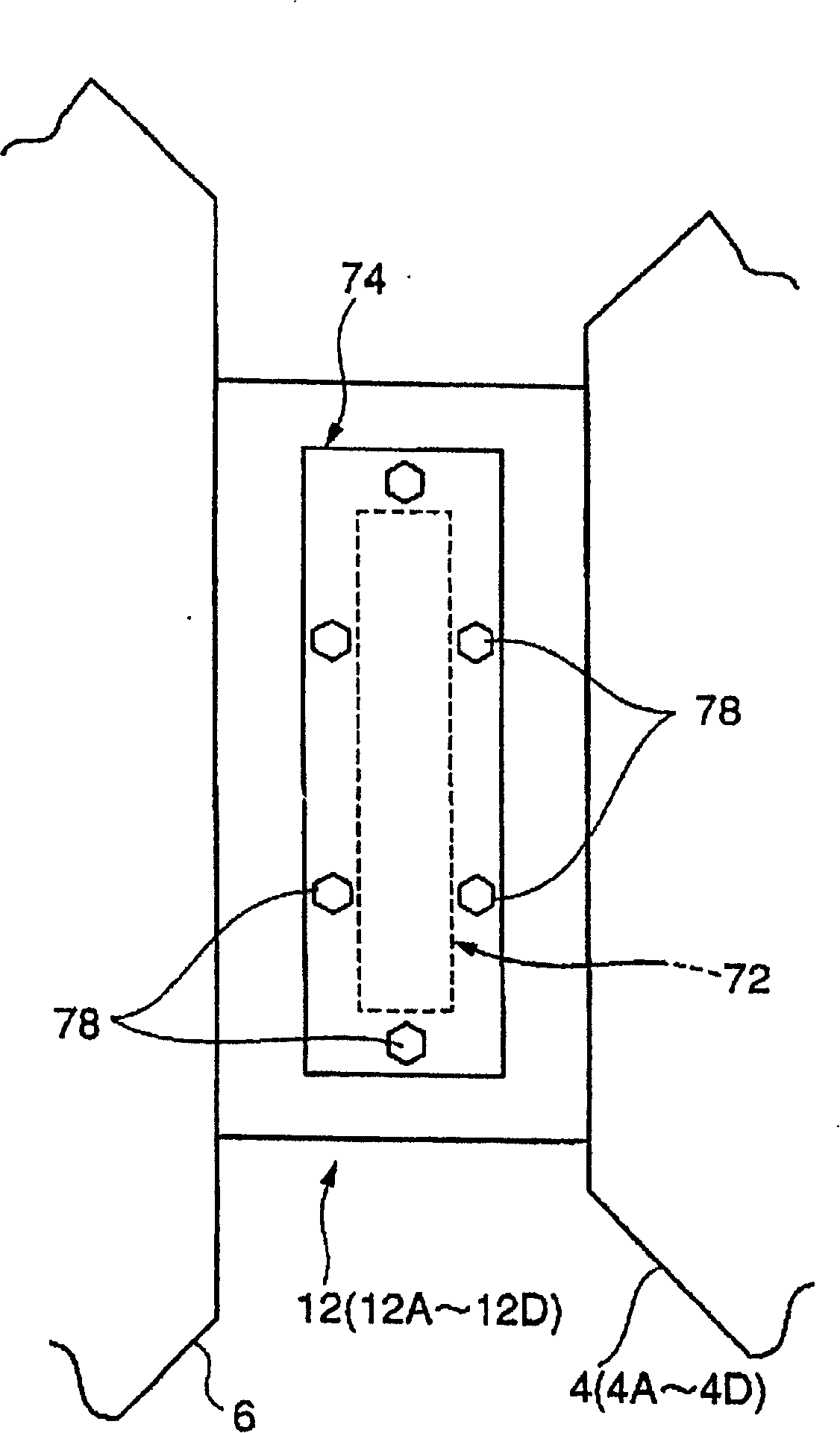

[0078] figure 1 It is a plan view showing an example of a processing system using the gate valve device of the present invention; FIG. 2 is an enlarged cross-sectional view showing the installation state of the first embodiment of the gate valve device of the present invention; image 3 It is the top view (top view) of the gate valve device; Figure 4 It is a perspective view showing the installation state of the valve body and the valve body drive mechanism from the front; Figure 5 It is a perspective view showing the installed state of the valve body and the valve body driving mechanism from the rear; FIG. 6 is an action explanatory diagram for explaining the action of the first embodiment of the gate valve device; Figure 7 It is a process chart showing the flow of seal member replacement.

[0079] Such as figure 1 As shown, the processing system 2 mainly includes: a plurality of (for example, 4) processing chambers 4A, 4B, 4C, 4D, a common hexagonal transfer chamber 6 ...

no. 2 example

[0112] Next, a second embodiment of the gate valve device of the present invention will be described.

[0113] Fig. 8 is an operation explanatory diagram for explaining the operation of the second embodiment of the gate valve device of the present invention. However, the same components as those shown in FIG. 6 are denoted by the same reference numerals, and description thereof will be omitted. In addition, in FIG. 8, only the main part of a gate valve device is shown.

[0114] In the case of the above-mentioned first embodiment, the recessed contact avoiding step 70 is formed on the mounting surface of the loading and unloading port 37 to avoid contact with the sealing member 68 for maintenance when the valve body 44 is assembled. In the second embodiment, the contact-avoiding stepped portion 70 is provided on the surface peripheral portion of the valve body 44 . Wherein, other structures are the same as those of the first embodiment. Specifically, the valve body 44 is for...

no. 3 example

[0117] Next, a third embodiment of the gate valve device of the present invention will be described.

[0118] Figure 9 is a sectional view showing a third embodiment of the gate valve device of the present invention. However, the same components as those described above are denoted by the same reference numerals, and description thereof will be omitted. In addition, in Figure 9 Only the main part of the gate valve device is indicated in .

[0119] In the above-mentioned first and second embodiments, the valve body supporting member 48 of the valve body driving mechanism 46 is rotatable, but in the third embodiment, the valve body supporting member 98 is formed in a rod shape, and can be moved up and down. The structure of the direction of movement. Further, a valve body 44 capable of advancing and retreating is provided at the front end portion of the valve body supporting member 98 . Furthermore, the frame body 36 is extended upward to form a rectangular cross-section,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com