Water system corn protein pseudo-emulsion and its preparation method

A corn gluten and corn technology, applied in the field of water-based corn gluten pseudoemulsion and its preparation, can solve problems such as no successful reports, and achieve the effects of avoiding inflammability and explosion, wide application, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Take the components in the following parts by weight (in grams):

[0042] Corn protein 10

[0043] Ethanol 56

[0044] Glycerin 2

[0045] distilled water 34

[0046] Wherein, the above-mentioned zein is gliadin extracted from corn.

[0047] Complete the preparation of water system corn gluten pseudo-emulsion with the following steps:

[0048] (1) zein is dissolved in ethanol with described weight portion, is made into zein alcohol solution;

[0049] (2) the zein alcohol solution was mixed with the glycerin of the weight portion, stirred for 0.5 hour, and obtained the plasticizer-containing zein alcohol solution;

[0050] (3) Mix the plasticizer-containing zein alcohol solution with the water by weight, stir for 0.5 hour, and filter in a conventional method to obtain a water-based zein pseudo-emulsion.

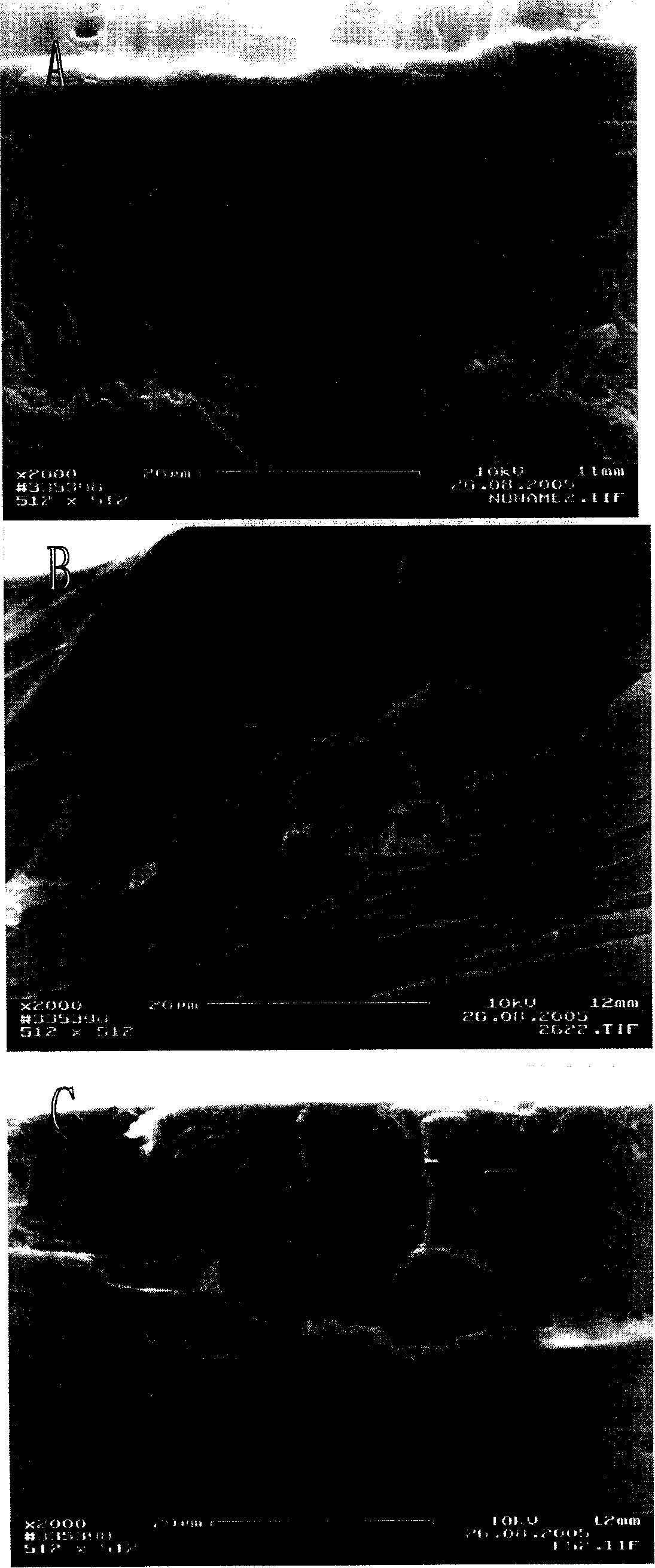

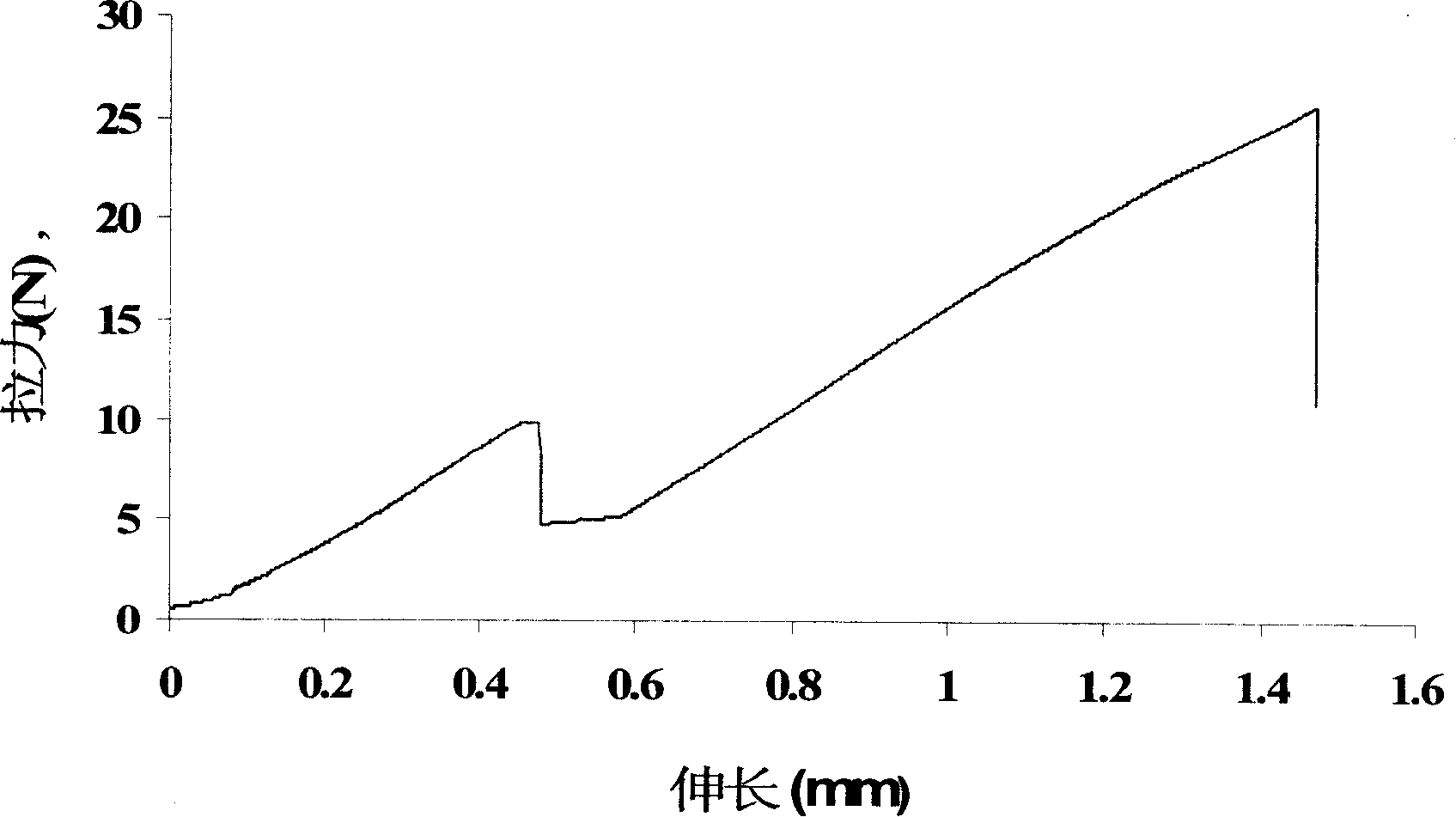

[0051] The above-mentioned aqueous corn protein pseudo-emulsion filtrate can also be poured into a Teflon mold, dried in an oven, and the solvent is evaporated to...

Embodiment 2

[0053] Take the components in the following parts by weight (in grams):

[0054] corn protein 2

[0055] Ethanol 20

[0056] Polyethylene glycol 400 0.1

[0057] distilled water 77

[0058] Wherein, the above-mentioned zein is gliadin extracted from corn.

[0059] Complete the preparation of water system corn gluten pseudo-emulsion with the following steps:

[0060] (1) zein is dissolved in ethanol with described weight portion, is made into zein alcohol solution;

[0061] (2) Zein prion alcohol solution was mixed with the polyethylene glycol 400 of described weight part, stirred for 0.8 hour, obtained containing plasticizer zein urein alcohol solution;

[0062] (3) Mix the plasticizer-containing zein alcohol solution with the water by weight, stir for 0.8 hours, and filter in a conventional method to obtain a water-based zein pseudo-emulsion.

[0063] The above-mentioned aqueous corn protein pseudo-emulsion filtrate can also be poured into a Teflon mold, dried in an ove...

Embodiment 3

[0065] Take the components in the following parts by weight (in kilograms):

[0066] Corn protein 20

[0067] Ethanol 65

[0068] Plasticizer 2

[0069] distilled water 20

[0070] Wherein, the above-mentioned zein is gliadin extracted from corn.

[0071] Complete the preparation of water system corn gluten pseudo-emulsion with the following steps:

[0072] (1) zein is dissolved in ethanol with described weight portion, is made into zein alcohol solution;

[0073] (2) the zein alcohol solution is mixed with the plasticizer (glycerin and polyethylene glycol 1500 is a 1: 1 mixed solution by volume ratio) of said weight portion, stirred for 1 hour to obtain the plasticizer-containing zein alcohol solution;

[0074] (3) Mix the plasticizer-containing zein alcohol solution with the water of the weight portion, stir for 1 hour, and filter in a conventional method to obtain a water-based zein pseudo-emulsion.

[0075] The above-mentioned aqueous corn protein pseudo-emulsion fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com