High property magnetic rheological fluid using carbon nono tube as anti-sedimentation agent and its preparation method

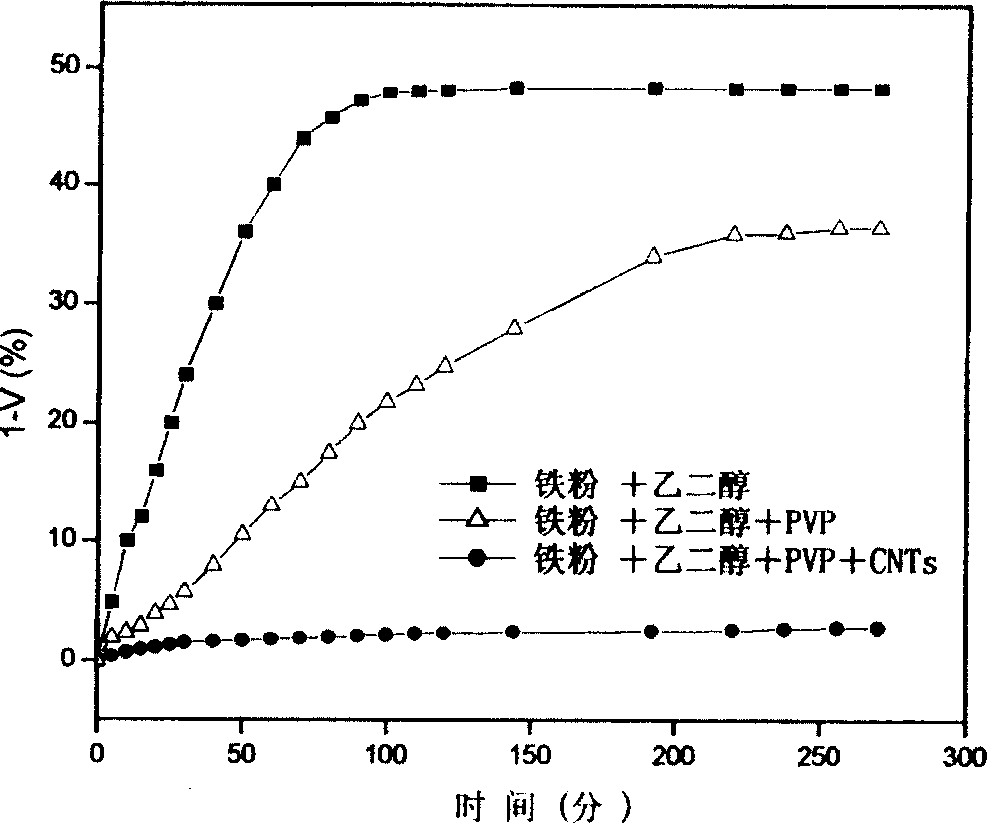

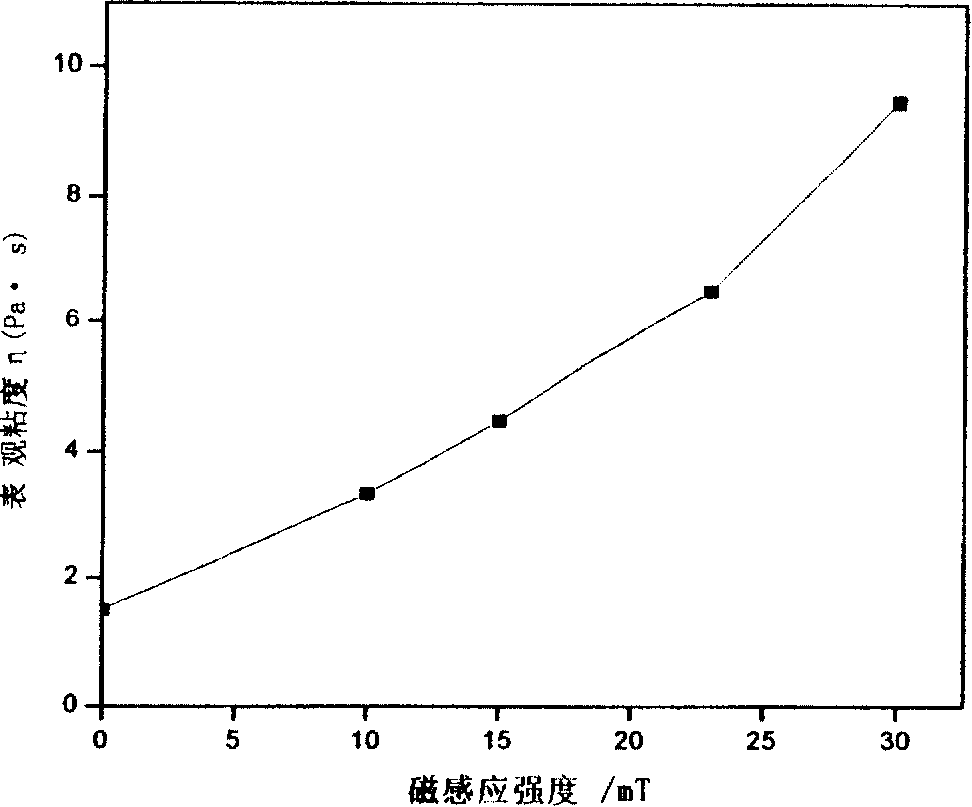

A magnetorheological fluid and anti-sedimentation agent technology, applied in the direction of magnetic fluid, inductor/transformer/magnet manufacturing, electrical components, etc., can solve the problem of reducing shear yield stress, increasing zero-field viscosity of magnetorheological fluid, and reducing thermal stability To solve the problems of chemical stability and other issues, achieve the effect of high shear stress, low zero-field viscosity and good sedimentation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The raw materials used in the embodiment are as follows:

[0027] Reduced iron powder (analytical grade) was provided by China National Pharmaceutical (Group) Shanghai Chemical Reagent Company.

[0028] Ethylene glycol (analytical grade) was provided by Shanghai Sanaisi Reagent Co., Ltd.

[0029] Carbon nanotubes (CNTs), Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences, tube diameter 8-15nm, tube length about 50μm, purity>95wt%, specific surface area>233m 2 / g.

[0030] Polyvinylpyrrolidone (PVP), number average molecular weight 2500, product of Polymer Science Company.

[0031] Graphite powder (industrial grade), Qingdao Yanyu Graphite Chemical Co., Ltd.

[0032] The ratio of raw materials used is as follows:

[0033] 61 parts (weight) of reduced iron powder

[0034] 34 parts (weight) of ethylene glycol

[0035] Carbon nanotube 0.6 part (weight)

[0036] 4.4 parts (weight) of polyvinylpyrrolidone (PVP)

[0037] Preparation of magnetorheological ...

Embodiment 2

[0046] The ratio of raw materials used is as follows:

[0047] 70 parts (weight) of reduced iron powder

[0048] 22.2 parts (weight) of ethylene glycol

[0049] Carbon nanotube 0.8 part (weight)

[0050] 7 parts of PVP (weight)

[0051] 1 part of graphite powder (weight)

[0052] Preparation of magnetorheological fluid:

[0053] Divide ethylene glycol into two parts, add PVP to one part, and stir to fully dissolve it. Disperse the reduced iron powder and carbon nanotubes into another part of ethylene glycol, stir until they are evenly dispersed, and the stirring speed is 200-500rpm. Mix the above two mixed liquids under high-speed stirring for 10-30 minutes, and the stirring speed is 2500-3500 rpm.

[0054] The determination of the properties of the prepared magnetorheological fluid is similar to that of Example 1, and its sedimentation performance and magnetorheological properties are also similar to the results shown in Example 1.

Embodiment 3

[0056] The ratio of raw materials used is as follows:

[0057] 64.8 parts (weight) of reduced iron powder

[0058] 26.1 parts (weight) of ethylene glycol

[0059] Carbon nanotube 0.3 part (weight)

[0060] 5.6 parts (weight) of polylactic acid

[0061] 3.2 parts (weight) of graphite powder

[0062] Preparation of magnetorheological fluid:

[0063]Divide ethylene glycol into two parts, add polylactic acid to one part, and stir to fully dissolve it. Disperse the reduced iron powder, graphite, and carbon nanotubes into another portion of ethylene glycol, and stir until they are evenly dispersed at a stirring speed of 200-500rpm. Mix the above two mixed liquids under high-speed stirring for 10-30 minutes, and the stirring speed is 2500-3500 rpm.

[0064] The determination of the properties of the prepared magnetorheological fluid is similar to that of Example 1, and its sedimentation performance and magnetorheological properties are also similar to the results shown in Examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com