Brushes for a dynamo-electric machine

A brush, commutated motor technology, applied to circuits, current collectors, electrical components, etc., can solve the problems of increasing the thermal load of the commutator and sliding contact system, unevenness of the motor, heating of the commutator, etc., to improve the surface Pressure curve graph, shorten start-up time, avoid tilting/topping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

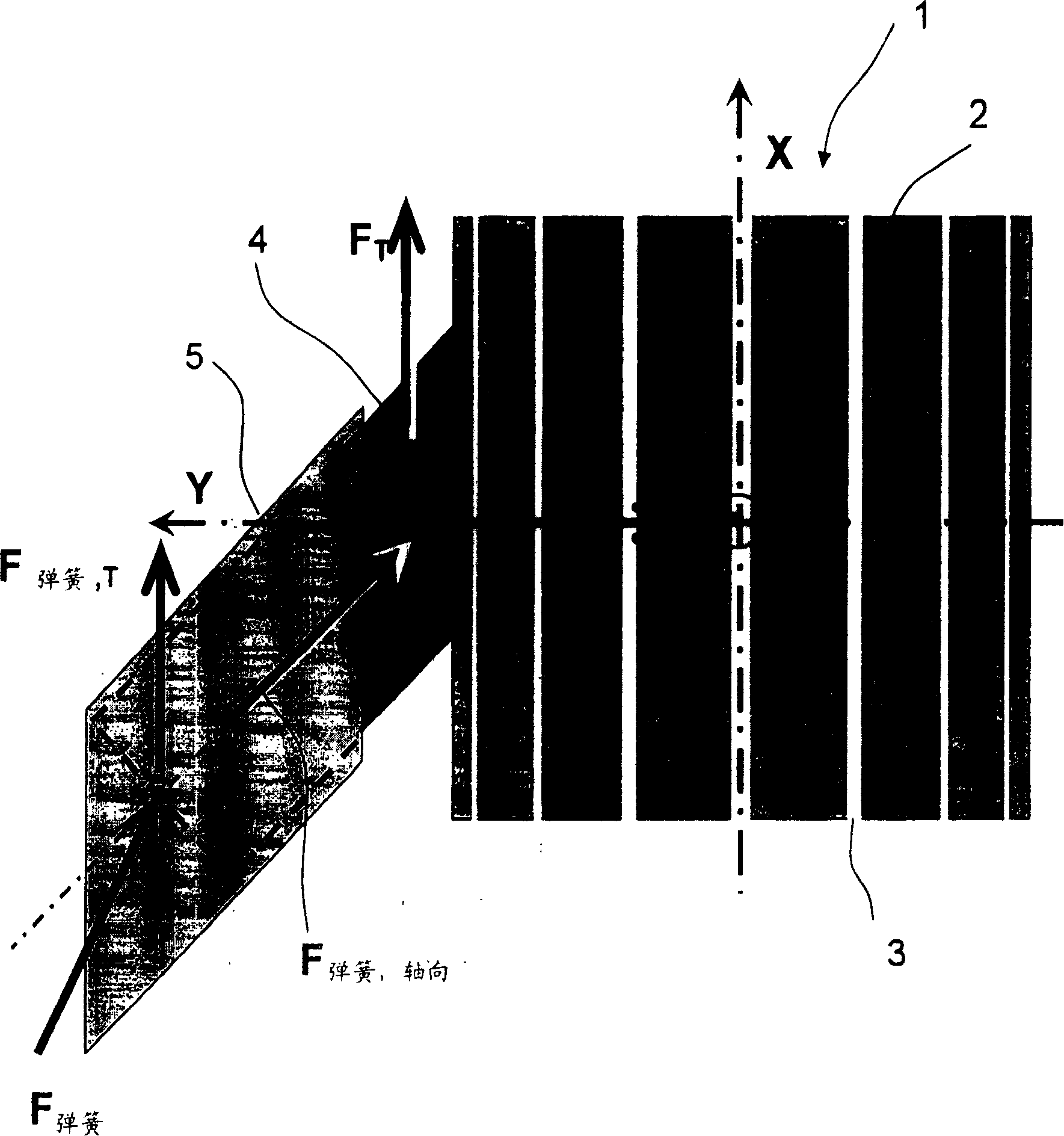

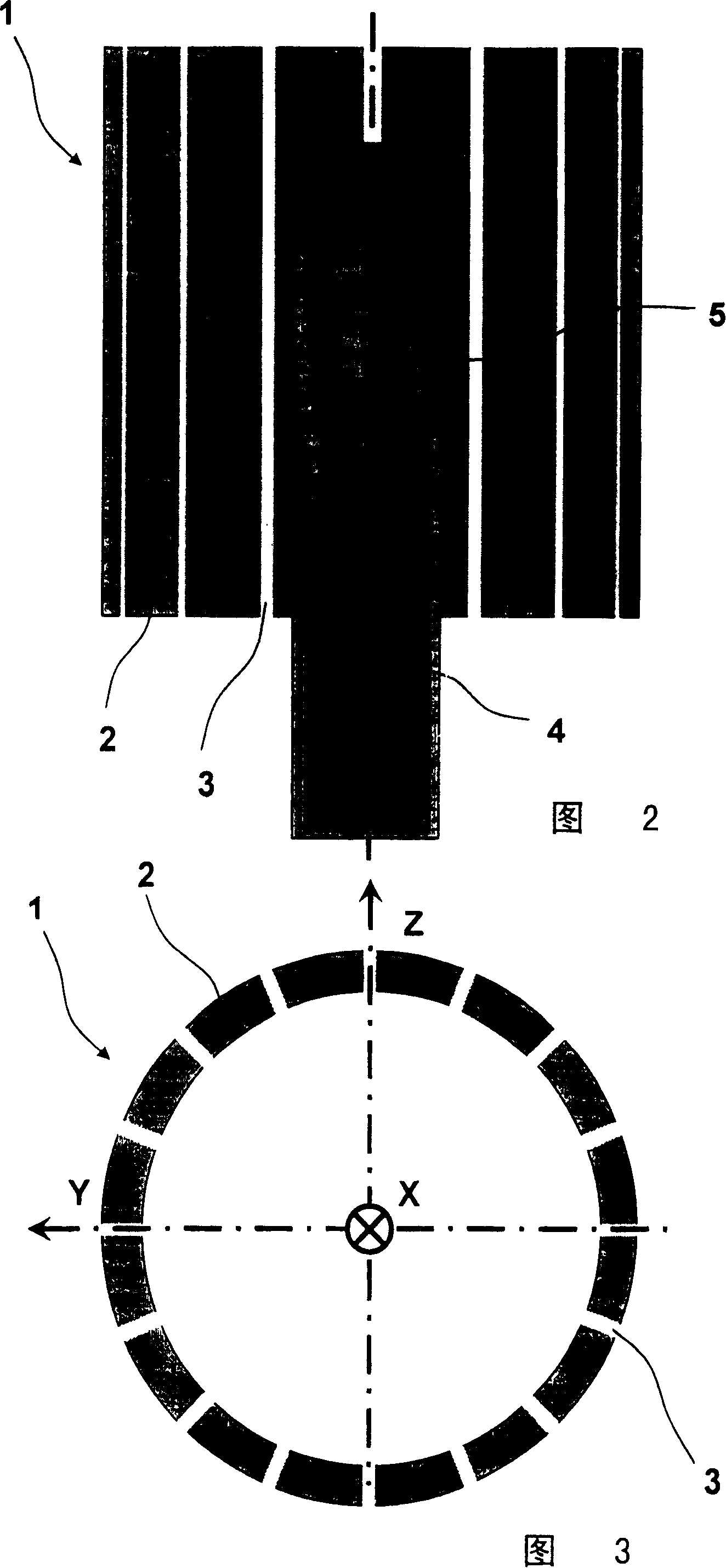

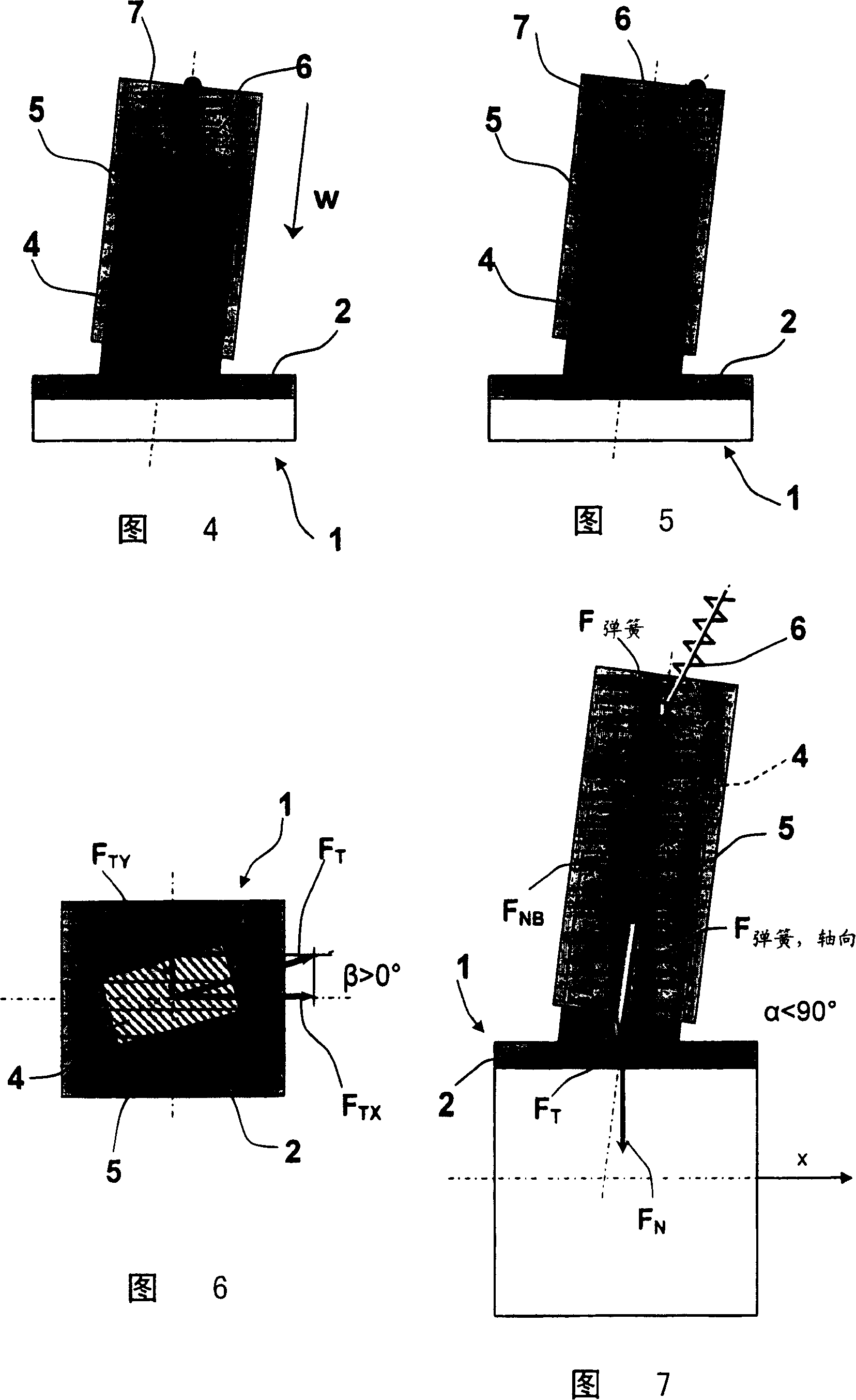

[0029] A motor, especially a commutator ( figure 1 to 3) There are a plurality of commutator segments 2 which extend longitudinally, ie parallel to the axis of rotation x of the electric motor, on the outer circumference of the commutator 1 . The commutator segments 2 are separated from one another by slots or grooves 3 . The brushes 4 bear against the commutator segments 2 in the y-direction. The brushes 4 are pressed against the commutator segments 2 by a brush guide 5 . Pressure is applied to the commutator segment 2 by a spring element, in particular a spring 6 ( FIGS. 4 , 5 ).

[0030] Such as figure 1 As shown, the brush 4 rotates about the z-axis in the xy plane, so that the brush 4 presses against the commutator segment 2 in an oblique direction w. Relative to the direction w, a spring force F 弹簧 Continue to tilt in the xy plane. A spring 6 ( FIGS. 4 , 5 ) presses the brush 4 against the commutator segments 2 of the commutator 1 .

[0031] So the spring force F ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com