Method for preparing dimethyl dichlorosilane through cracking

The technology of dimethyldichlorosilane and methylchlorosilane is applied in the field of preparation of dimethyldichlorosilane, can solve the problems of harsh reaction conditions, high catalyst price and high reaction temperature, and achieves easy reaction, simple process, The effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

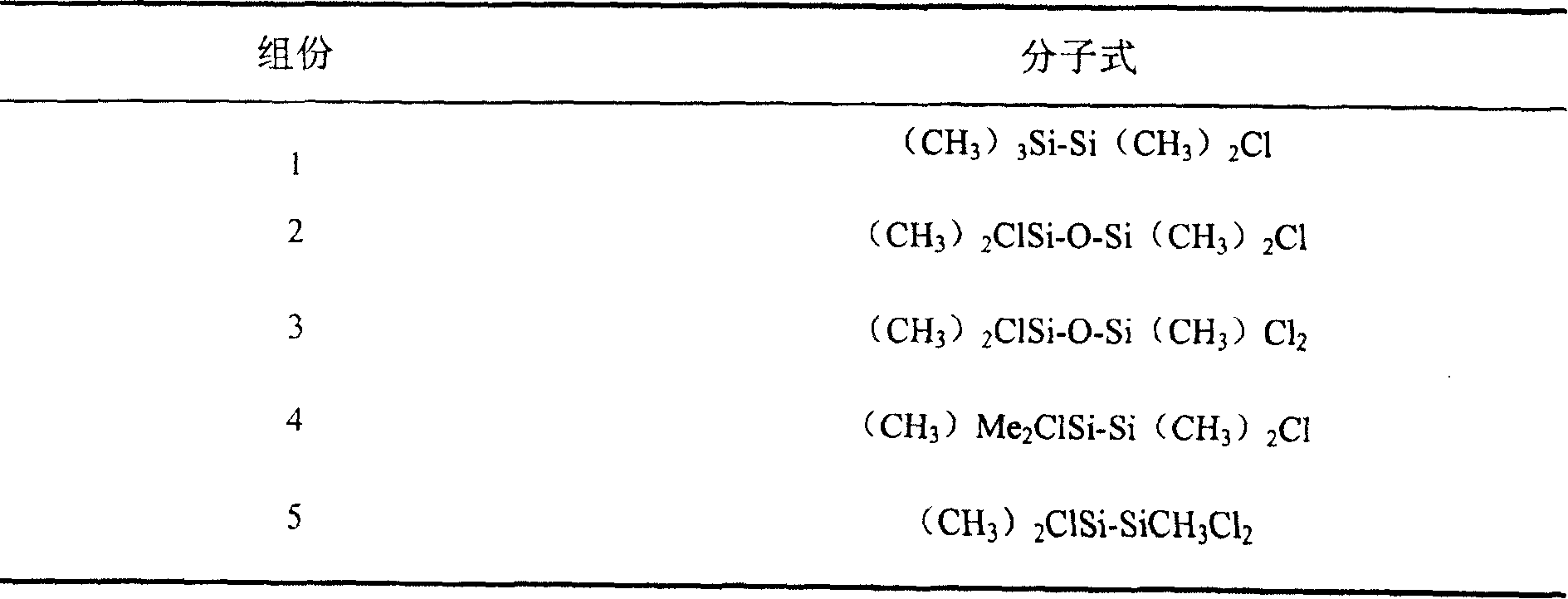

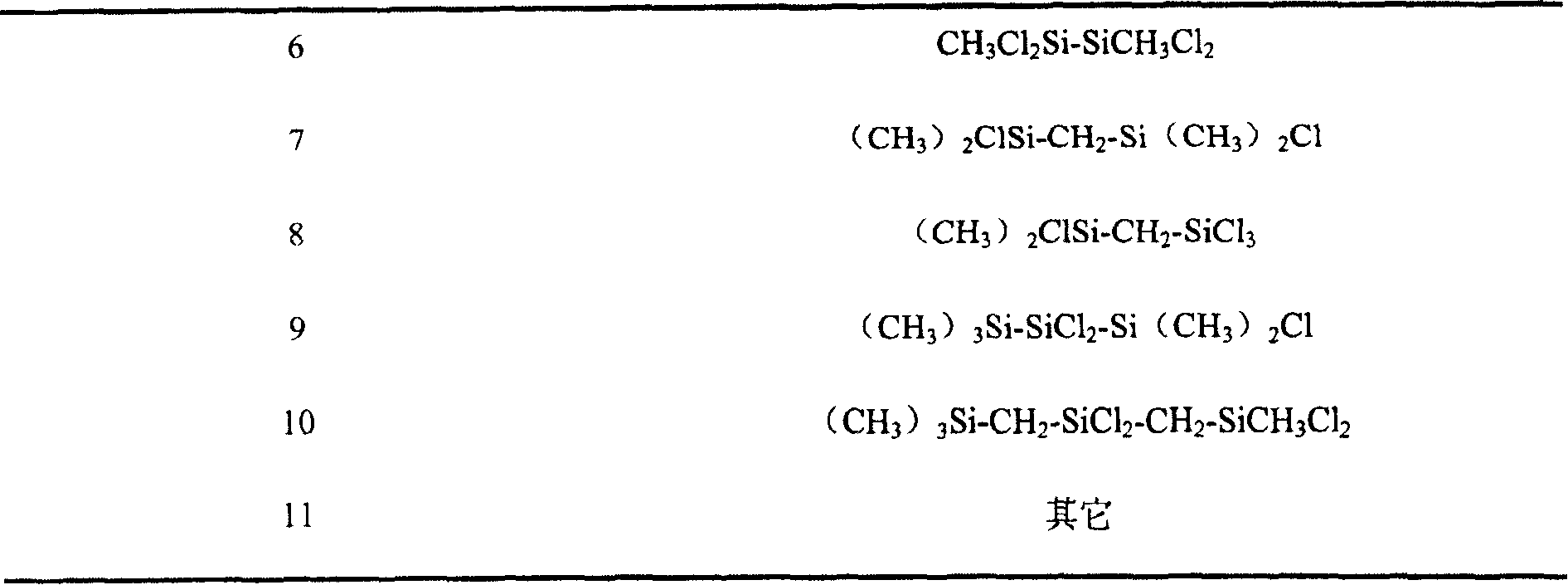

[0036] 100 g of high boilers (see Table 1 for composition), 10 g of concentrated sulfuric acid, and 5 g of aluminum powder were added to the autoclave. Raise the temperature to the reaction temperature. At 220°C, the reaction time is 3-5 hours, and the pressure is maintained at 1.0-2.5 MPa. The composition of the lysate is shown in Table 2. (The product contains part of the boiling point lower than CH 3 HSiCl 2 components, the content is about 3%)

[0037] Table 2 Product Gas Chromatography Analysis

[0038]

Embodiment 2

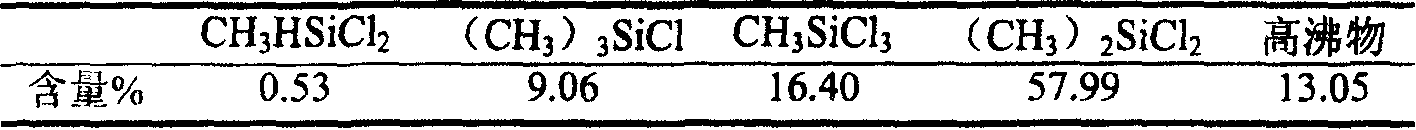

[0040] Reaction process is the same as embodiment 1, and high boiler is 100g, and concentrated sulfuric acid is 15g, and aluminum powder is 10g, is warming up to reaction temperature, and at 230 ℃, reaction time is 3~5 hours, and pressure is maintained at 1.0~2.5MPa. The composition of the lysate is shown in Table 3. (Contain part boiling point lower than MeHSiCl in the product 2 components, the content is about 3%)

[0041] Table 3 Product Gas Chromatography Analysis

[0042]

Embodiment 3

[0044] The reaction process is the same as in Example 1. The high boiler is 100g, the concentrated sulfuric acid is 20g, and the aluminum powder is 15g. The temperature is raised to the reaction temperature. At 230° C., the reaction time is 3 to 5 hours, and the pressure is maintained at 1.0 to 2.5 MPa. The composition of the lysate is shown in Table 4. (Contain part boiling point lower than MeHSiCl in the product 2 components, the content is about 3%)

[0045] Table 4 Product Gas Chromatography Analysis

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com