Protective method for metal surface wearing and stream erosion resistance

A metal surface, cavitation technology, applied to the components of pumping devices for elastic fluids, non-variable-capacity pumps, pump devices, etc., can solve problems such as cavitation and surface wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] This method is described in conjunction with accompanying drawing: method comprises the following steps:

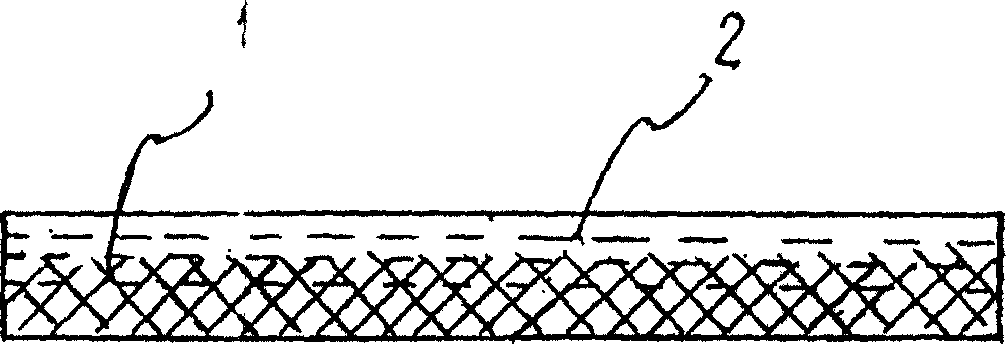

[0012] 1) by figure 1 As shown, the glass cloth (1) of a certain thickness is pressed into the polymer material (2) by hot pressing, and combined with the polymer material, the side of the polymer material layer reinforced by the grid glass cloth A thin layer of wear-resistant and cavitation-resistant reinforced polymer material veneer is formed, and the other side is exposed to a grid glass cloth with a thickness of 0.1-0.8mm. The polymer material can be ultra-high molecular weight polyethylene UHMW-PE, and the grid glass cloth is glass fiber;

[0013] 2) Brush the metal surface to be anti-corrosion and scrub it with acetone;

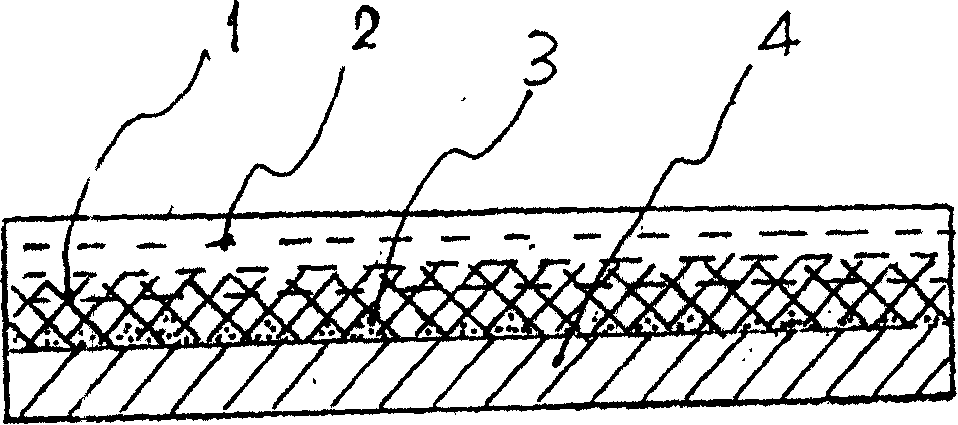

[0014] 3) by figure 2 As shown, the grid glass cloth (1) exposed on the side of the polymer material is pasted on the metal surface (4) to be protected through epoxy resin (3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com