Apparatus for full optical fiber Q-switched laser by using butt joint loss variety

A loss-changing, all-fiber technology, which is applied in the direction of lasers, laser components, and the structure/shape of active media, can solve problems such as increasing the insertion loss of resonators, increasing the difficulty of practical promotion, and reducing overall performance, so as to increase transmission loss. , Reduce mechanical stability requirements, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

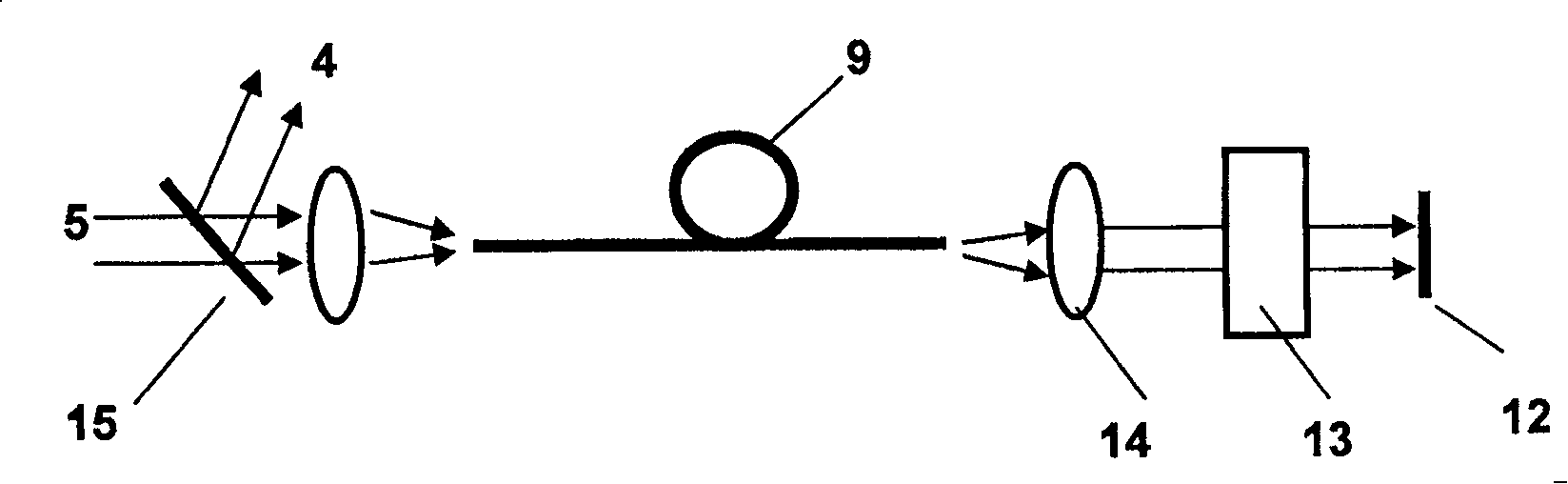

[0036] The invention provides a method for generating all-fiber Q-switched laser by utilizing the change of butt loss, and its specific steps are as follows:

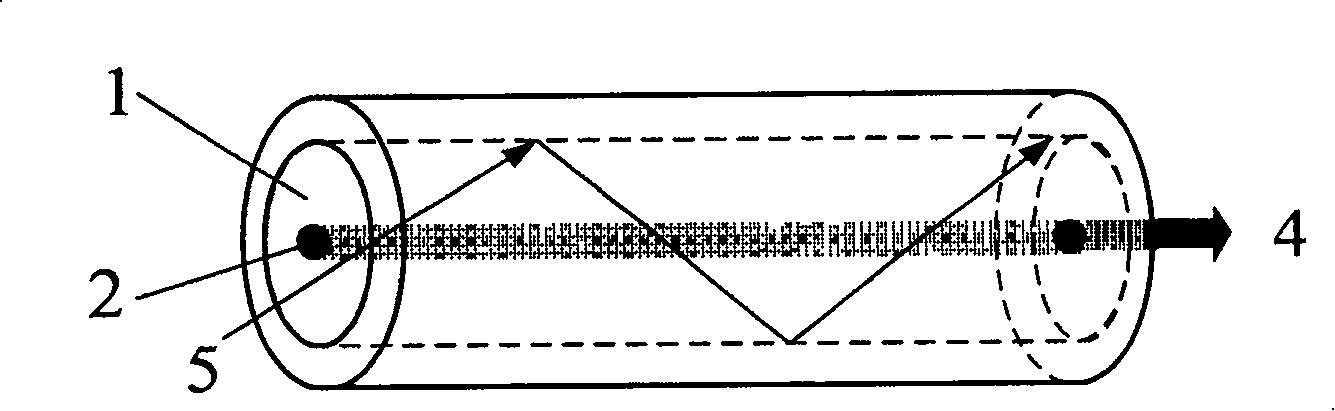

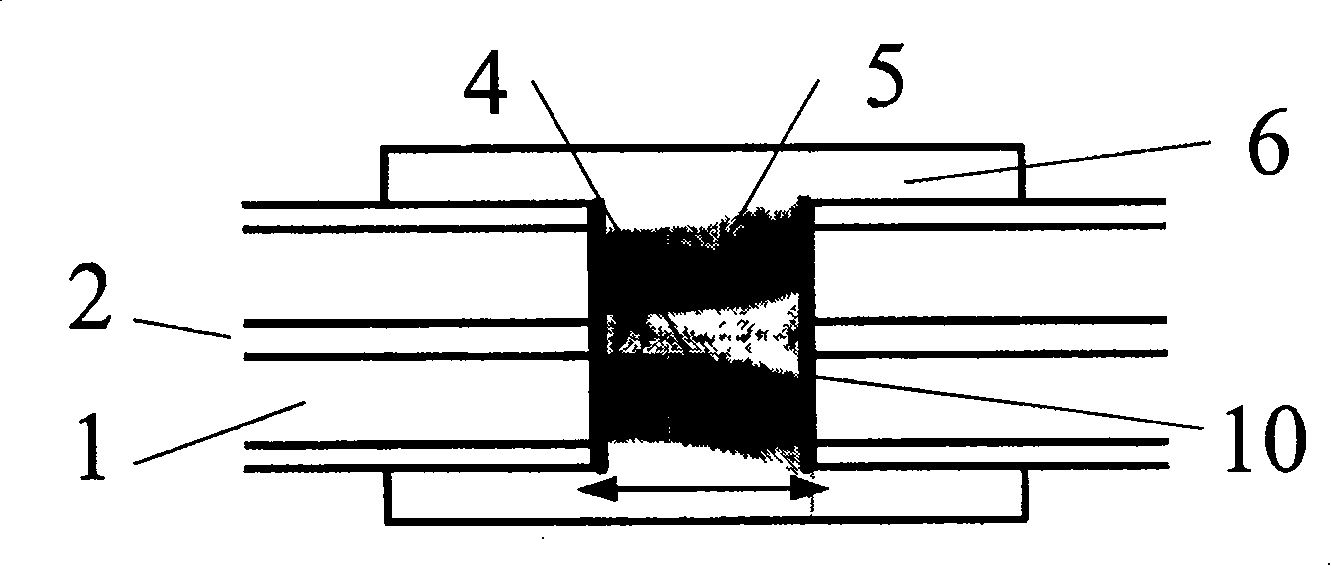

[0037]1) In the fiber laser, two or more sections of optical fiber are horizontally butt-jointed, and the two ends are bonded together, so that the fiber laser is in a high-Q state; the optical fiber used is double-clad optical fiber 1, or non-doped ordinary optical fiber 3 , the end face of the optical fiber is a plane or a spherical surface that is ground or polished vertically or at an angle, and the angles of grinding and polishing are the same during the angle grinding and polishing. When adjusting, you can choose the following ways to adjust:

[0038] a) The axial adjustment method is used to adjust the axial relative distance between the two butt end faces, which affects the gap loss of coupling transmission between optical fibers, and realizes Q-switching of fiber lasers;

[0039] b) Use the radial adjustment m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com