Atomizing ironing garment post treatment apparatus and treatment technique

A post-processing device and post-processing solution technology are applied in the directions of spray/jet textile material processing, solvent processing, textile material processing, etc., to achieve the effects of reducing post-processing costs, simplifying equipment and increasing economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

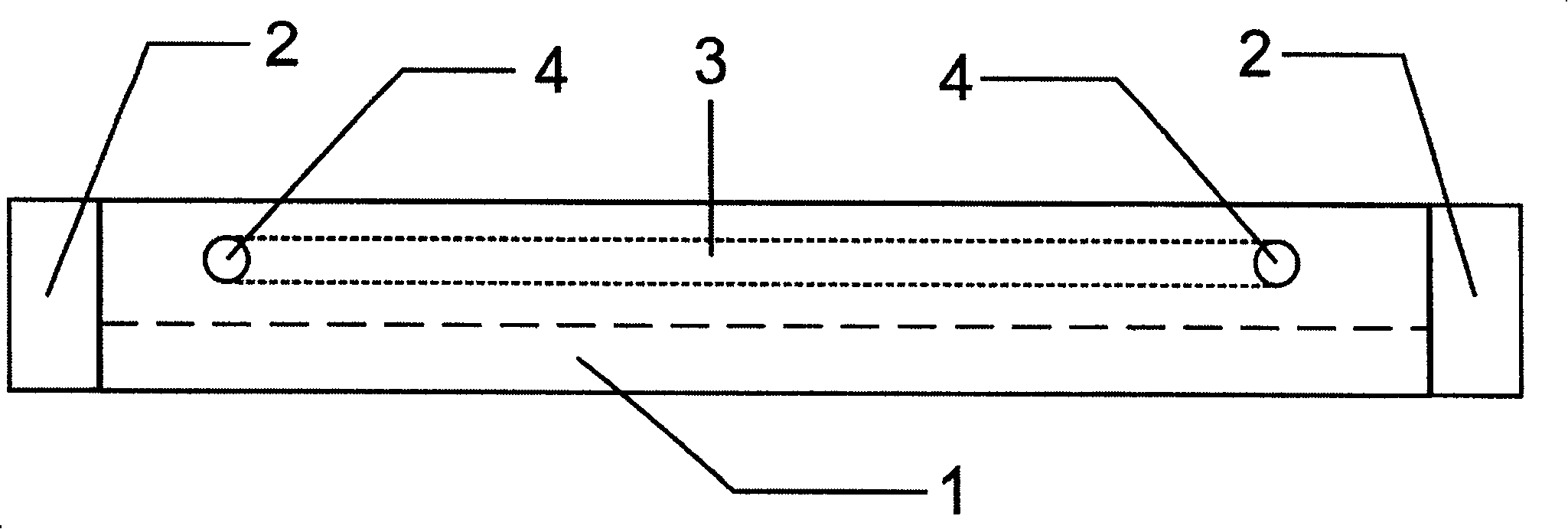

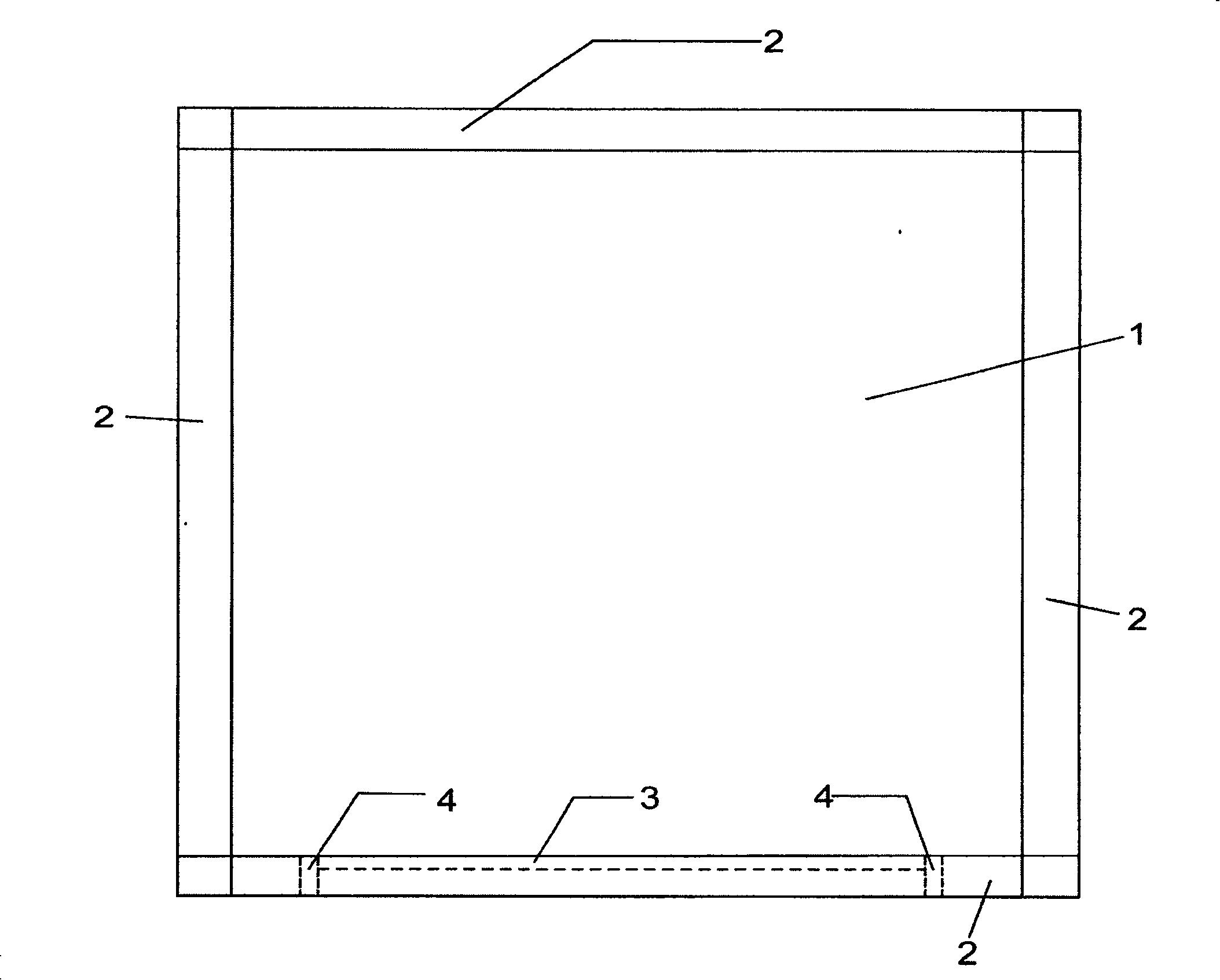

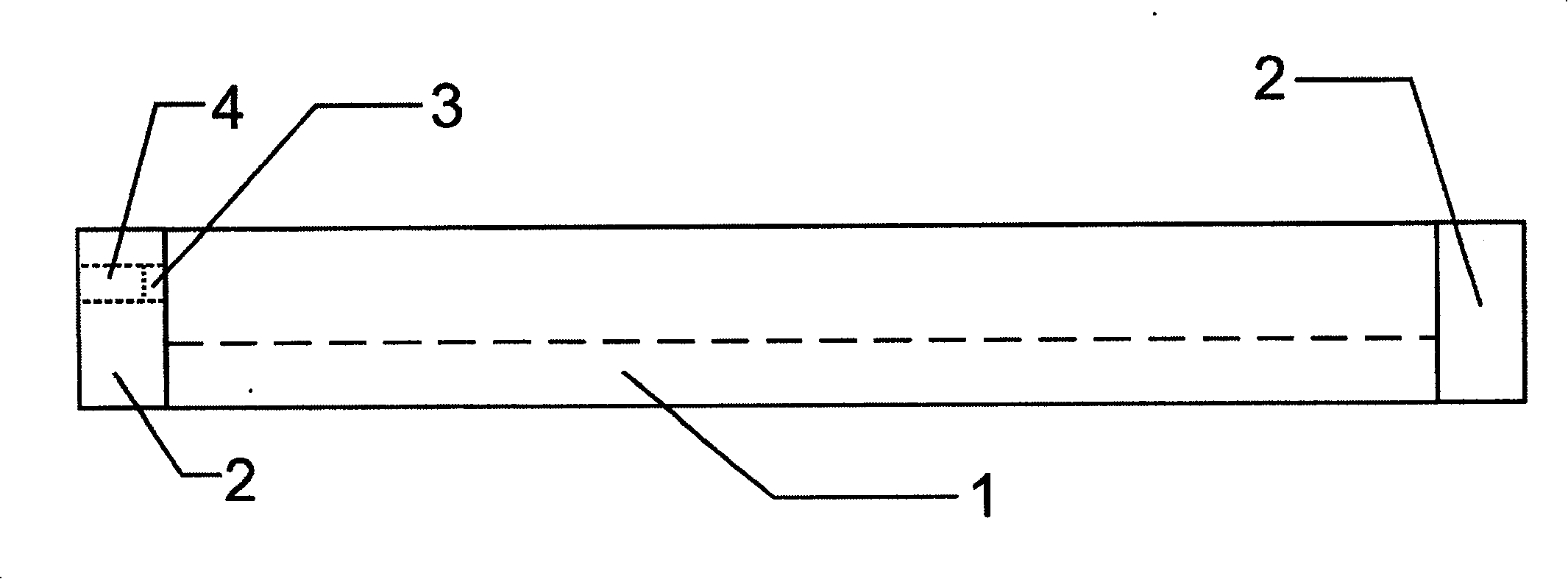

[0015] A spray ironing garment post-processing device, comprising a processing box and a rolling plate used in conjunction with the processing box. The processing box is composed of a garment box-shaped processing plate 1 and barriers 2 around it, on the inner side of the barrier There are diversion grooves 3 and diversion holes 4 communicating with the outside at both ends of the diversion grooves. The rolling plate slides on the clothing box type processing plate of the processing box, and the clothing on the clothing box type processing plate 1 is processed Light rolling.

[0016] A handle is installed on the rolling plate. The garment box type processing board is made of stainless steel plate or plastic plate or processed smooth wood. The side of the box-shaped processing board 1 that contacts the clothing is a smooth surface, with a length of 40-80 cm, a width of 50-90 cm, a thickness of 0.2-0.5 cm, and a height of 3 cm to 5 cm. , and the thickness is between 0.2-0.5 ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com