Semiconductor device and manufacturing method of the same

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of decreased electrical bonding area, disconnection, and increased connection resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

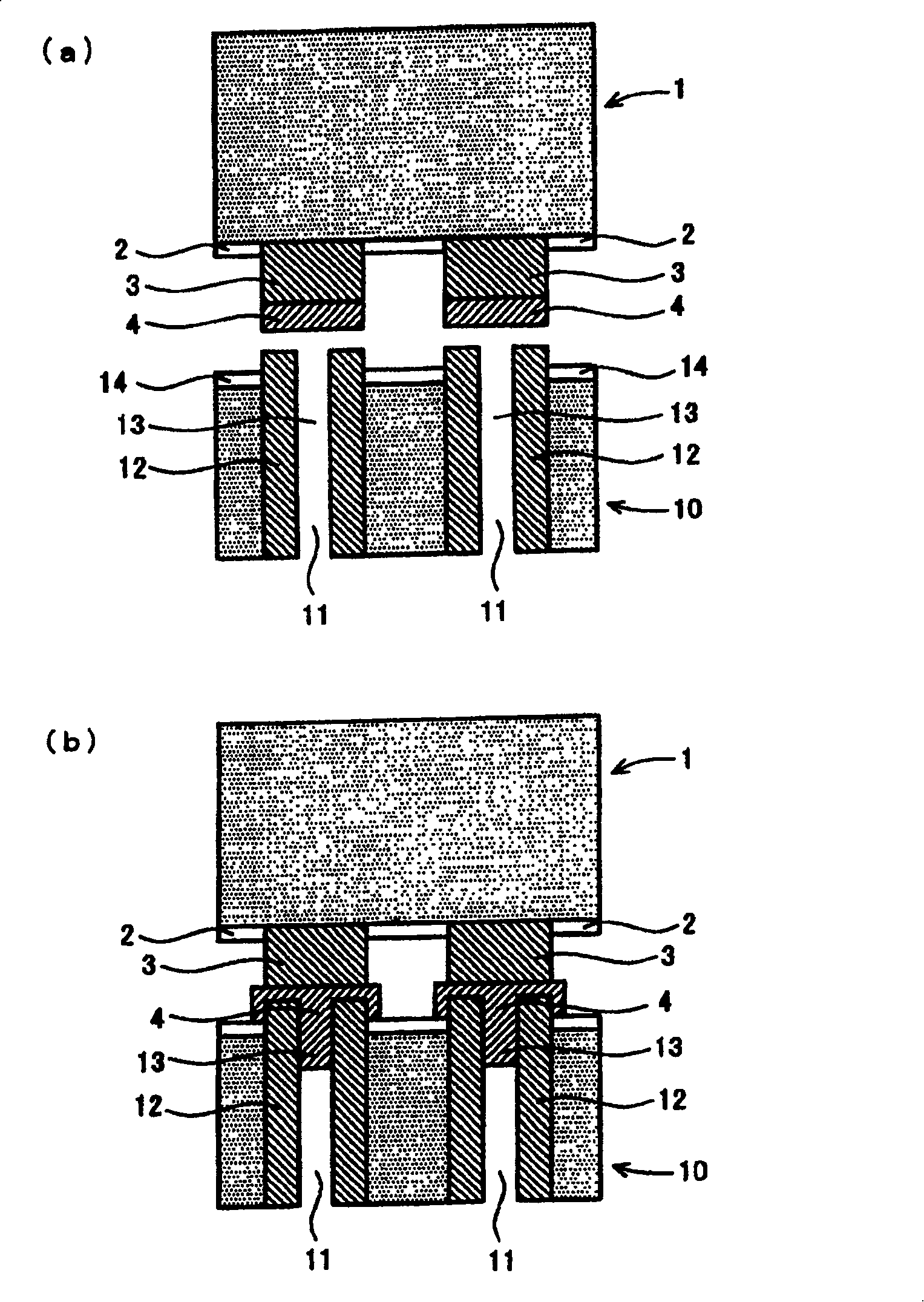

[0027] Such as figure 1 As shown in (a), a semiconductor integrated circuit (not shown) is formed on the surface of the first semiconductor chip 1, and a passivation film 2 made of a silicon nitride film (SiN film) is formed in order to protect the semiconductor integrated circuit. Then, a plurality of bump electrodes 3 are formed on the surface of the first semiconductor chip 1 as terminals for external connection of the semiconductor integrated circuit, and a low-melting point metal member 4 as an electrode connection member is attached to the front end thereof.

[0028] The plurality of bump electrodes 3 are made of metal such as copper, and can be formed using an electrolytic plating method. Its thickness is about 10 μm, and it is arranged at a fine pitch of about 20 μm or less. The low-melting-point metal member 4 is made of a metal different from the metal constituting the bump electrode 3 or the penetration electrode 12 described later, and is made of a different meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com