Method for preparing phenethylene through dehydrogenation of ethyl benzene

A technology for the dehydrogenation of ethylbenzene and styrene, applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of poor low-temperature performance of catalysts, high energy consumption of water vapor diluents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Composition of 0.1 g weight of 20% Cr 2 o 3 / 80%Al 2 o 3 The catalyst was loaded into a stainless steel reactor with a diameter of 5 mm, and the temperature was programmed to 500 °C at a rate of 20 °C / min. The catalyst was pretreated for 2 hours under N2 atmosphere, ethylbenzene was vaporized by a saturated steam generator, and then mixed with CO 2 Mixed to form raw material gas enters the catalyst bed layer for reaction. The reaction was carried out at 500 ° C, the pressure was normal pressure, CO 2 The molar ratio with ethylbenzene is 20:1, and the ethylbenzene flow rate is 0.42 mmol / hour, and its weight composition and investigation performance are shown in Table 1 and Table 2.

Embodiment 2~4

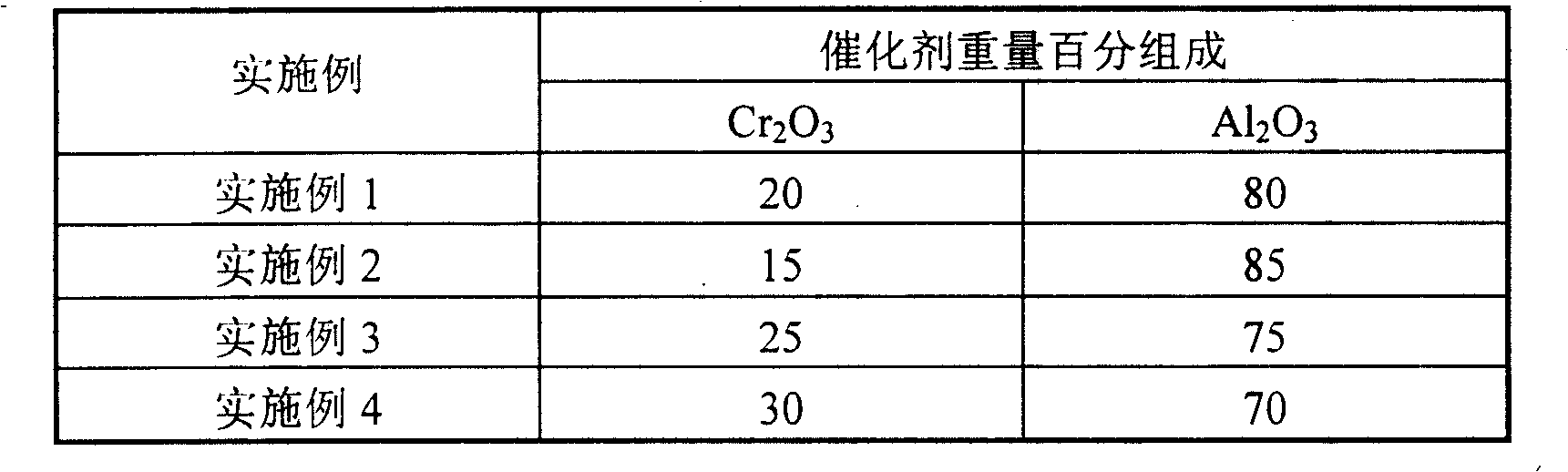

[0020] Prepare and evaluate catalyst by each steps and condition of embodiment 1, just change Cr 2 o 3 and Al 2 o 3 Component content, weight percent composition of catalyst, dehydrogenation performance and catalyst stability under carbon dioxide atmosphere are shown in Table 1 and Table 2 respectively.

[0021] The weight percent composition of table 1 catalyst

[0022]

[0023] Table 2 Catalyst dehydrogenation performance under carbon dioxide atmosphere

[0024] Example

Embodiment 5

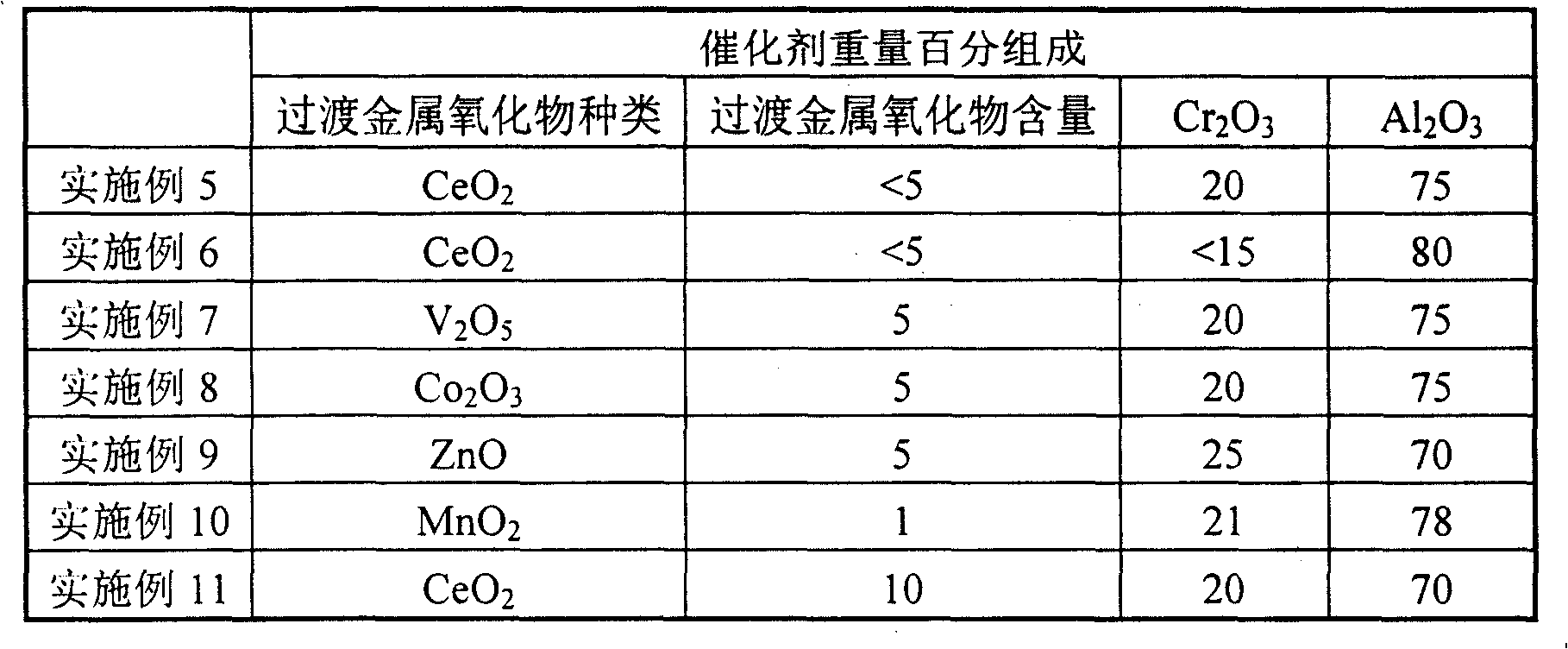

[0026] Composition of 0.1 gram weight percent as 5% CeO 2 / 20%Cr 2 o 3 / 75%Al 2 o 3 The catalyst was loaded into a stainless steel reactor with a diameter of 5 mm, the temperature was programmed to 500 ° C, and the heating rate was 20 ° C / min. The catalyst was in N 2 Under the atmosphere pretreatment for 2 hours, ethylbenzene was vaporized by a saturated steam generator, and then mixed with CO 2 Mixed to form raw material gas enters the catalyst bed layer for reaction. The reaction was carried out at 500 ° C, the pressure was normal pressure, CO 2 The molar ratio with ethylbenzene is 20:1, and the ethylbenzene flow rate is 0.42 mmol / hour, and its weight composition, evaluation results and performance are shown in Table 3, Table 4 and Table 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com