Preparation process and application of water resistant starch-base timber adhesive

A wood adhesive, starch-based technology, applied in the direction of adhesives, adhesive application devices, adhesive types, etc., can solve problems such as poor water resistance, and achieve the effects of improved water resistance, stable three-dimensional structure, and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Synthesis of starch-vinyl acetate cross-linked graft copolymer, using starch as raw material, after preparing starch emulsion with a concentration of 30-40% by mass, using hydrochloric acid as a catalyst and ammonium persulfate as an initiator, at pH 3-40 Within the range of 5, slowly add vinyl acetate monomer accounting for 75% to 85% of the mass ratio of starch to carry out graft copolymerization reaction, the grafting reaction temperature is 60-70°C, and the grafting reaction time is 2-4 hours; After 1-2 hours of grafting reaction, N,N'-methylenebisacrylamide cross-linking agent is added with a mass ratio of 0.2%-0.4% of starch and a mass concentration of 1%-2%. Both feeding and reaction are carried out under stirring, and the reaction product is starch-vinyl acetate cross-linked graft copolymer.

[0016] The mixing of starch-vinyl acetate cross-linked graft copolymer and auxiliary agent, using the synthesized starch-vinyl acetate cross-linked graft copolymer as the ...

Embodiment 2

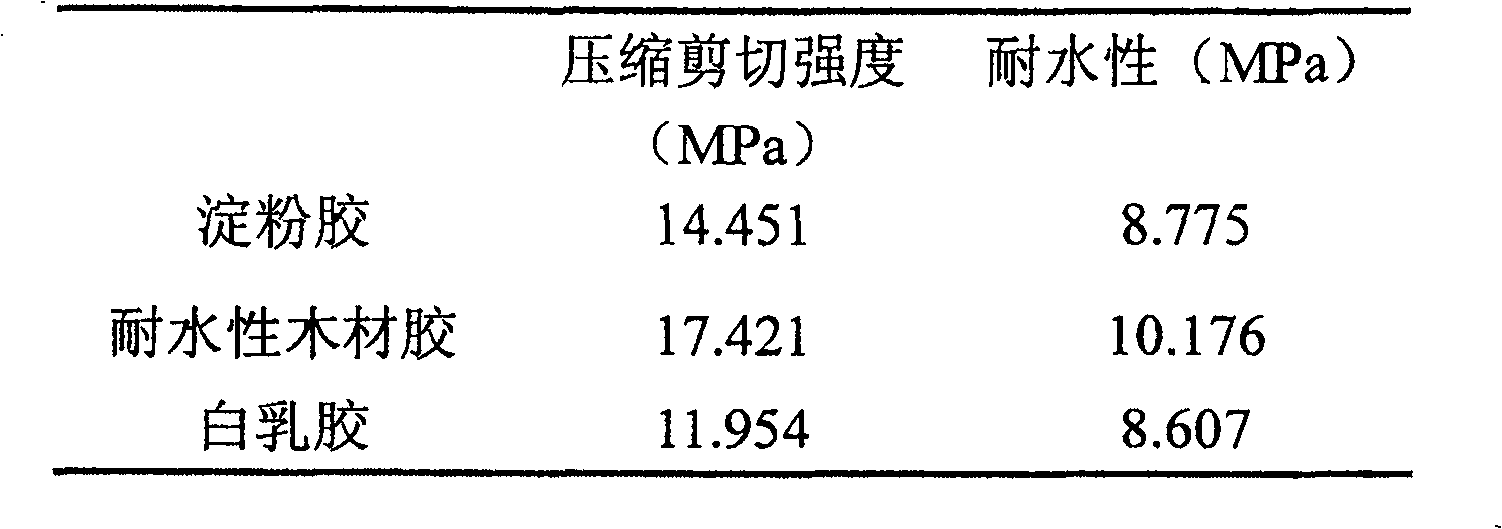

[0018] Commercially available white latex, starch glue and the compressive shear strength of water-resistant wood glue of the present invention and water resistance compare, can find from table 1, the compressive shear strength of water-resistant wood glue of the present invention and water resistance are all higher than commercially available. Sale of white latex and starch glue.

[0019] Table 1 Comparison of compressive shear strength and water resistance of three kinds of adhesives

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com